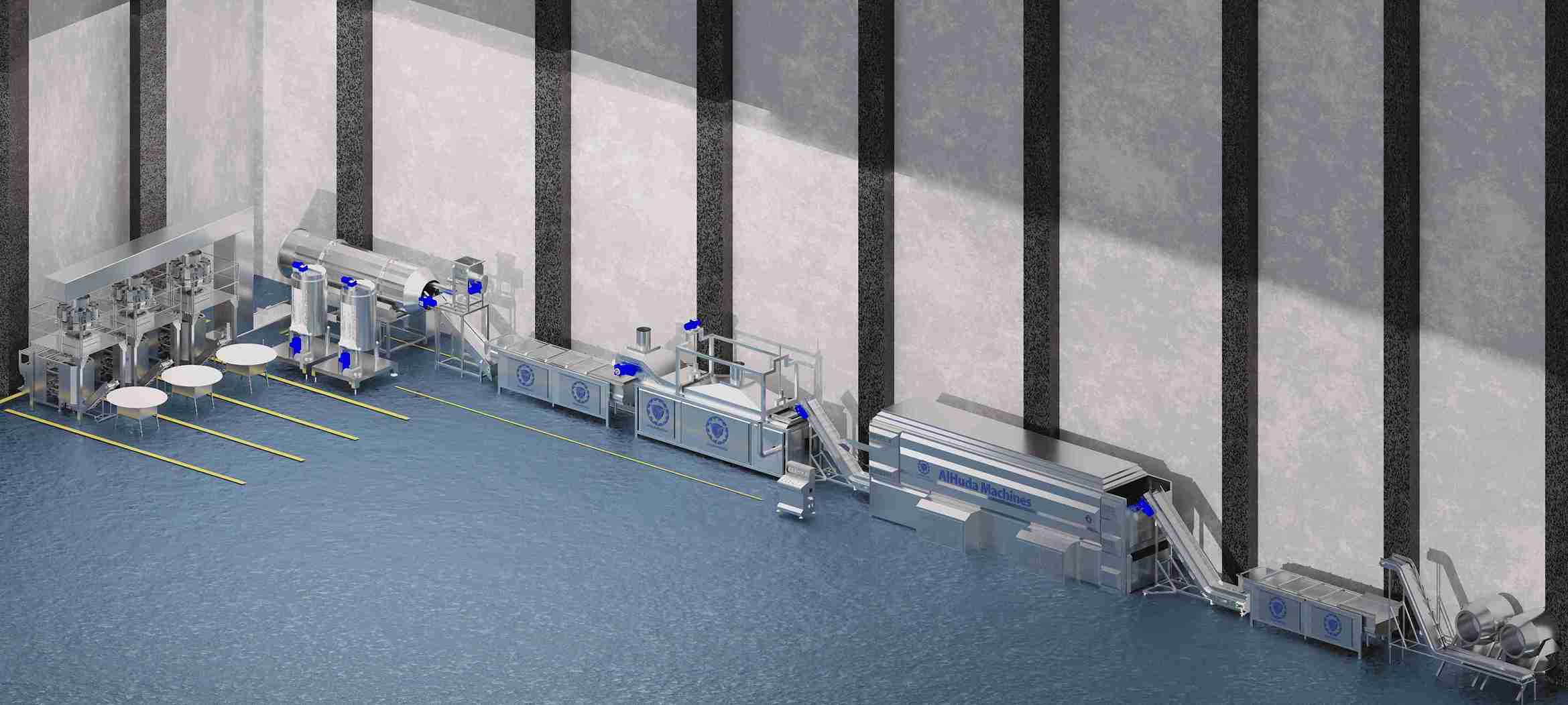

Candied peanut production line like Karak Kanaker

🥜🔥 Cracker Peanuts Production Line – Coated and Fried Peanuts

🔹 Overview: The cracker peanuts production line is an industrial system designed to prepare peanuts coated with a flavorful batter and then fried to create a crispy, delicious snack.

This line can be used to produce cracker peanuts in various flavors, such as cheese, barbecue, paprika, ketchup, chili, lemon, and more.

✅ Features of the Cracker Peanuts Line: Suitable for producing medium to large quantities. Flexible for changing flavors and coatings.

Produces a high-quality, crispy final product.

Fully or semi-automatic operation, depending on customer requirements.

Ability to use multiple flavorings.

The line consists of the following parts

1. Flour mixer

2. Flour coating pans

3. Vibrating feeder/dispenser

4. Frying machine

5. Conveyor belt to the oven

6. Peanut roasting and baking oven

7. Product conveyor belt

8. Sorting and cooling vibrator

9. Seasoning/flavoring machine

10. Flavor coating drum

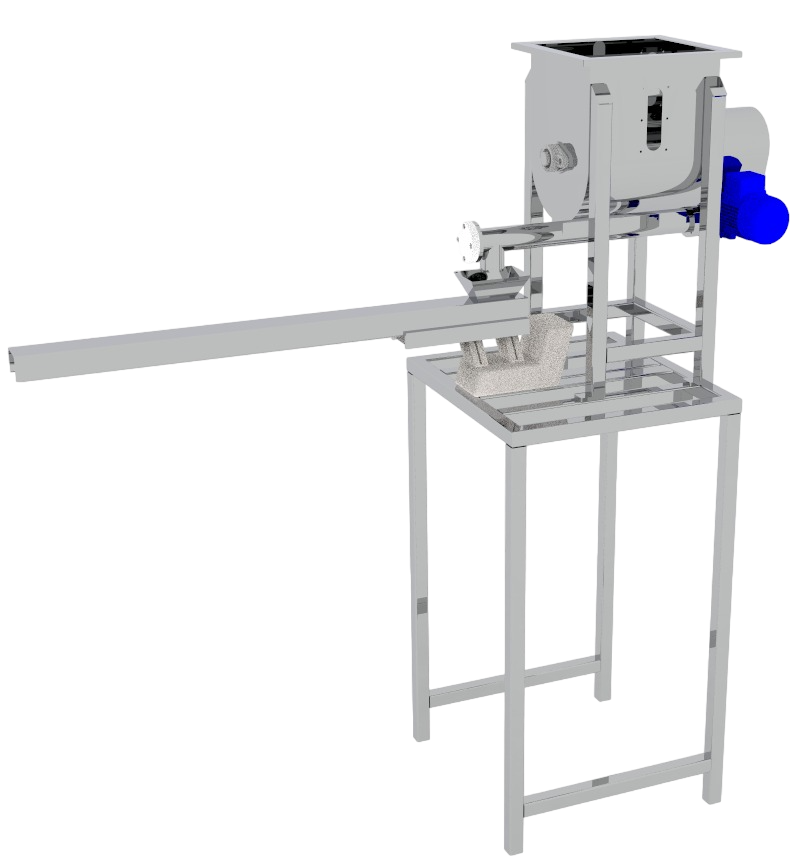

Flour mixer

High mixing efficiency for a homogeneous flour mixture of superior quality. The cylindrical flour mixer is specifically designed to be an essential part of the preparation stages in food production lines. It thoroughly mixes flour with water and other additives, ensuring precise and efficient preparation of dough or coatings for products such as coated peanuts, etc. Working principle and technical features:

1️⃣ Hygienic design made of food-grade 304 stainless steel. The mixer is entirely constructed from food-grade 304 stainless steel, which is resistant to rust and corrosion, making it ideal for the food industry. It offers: high resistance to acids and moisture; easy cleaning and sanitization; and a long lifespan without any color or taste alteration.

2️⃣ Homogeneous mixing function. The mixer is designed to effectively combine flour with water and additives (such as flavors, stabilizers, or colorants), ensuring a uniform and lump-free mix. Its rotating mechanism achieves perfect distribution of ingredients within the cylindrical tank.

3️⃣ Easy discharge via a screw conveyor. The bottom outlet allows the finished mixture to be discharged directly into a screw conveyor (available separately or as part of the production line), facilitating quick and clean transfer to subsequent production stages, eliminating the need for manual emptying.

4️⃣ Easy cleaning and maintenance. The mixer features an open top design and a smooth interior surface, making it easy to wash and clean after each production run. All corners are rounded to prevent material or bacterial buildup.

5️⃣ High electrical efficiency and flexible control. This mixer operates with a power of 3.75 kW, at a voltage of 380/220 V and a frequency of 50 Hz, ensuring strong and consistent mixing under all operating conditions. It can be connected to an inverter to adjust the mixing speed as needed. Technical specifications:

Material: Food-grade 304 stainless steel

Thickness: 2 mm

Power: 3.75 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 100 cm

Width: 90 cm

Height: 140 cm

Machine number: 001

Model: THV-2025AL-T

Country of origin: Turkey

Features of the flour mixer:

✔️ Hygienic and safe design made of food-grade stainless steel.

✔️ Efficient and rapid mixing of dry and liquid ingredients.

✔️ Easy emptying through a dedicated bottom outlet.

✔️ Ideal for coating mixes or initial preparation in peanut and chip production lines.

✔️ Easy to clean and maintain.

✔️ Economical energy consumption with excellent performance.

✔️ Suitable for continuous operation in food processing plants.

💡 The ideal mixer for ensuring high homogeneity and precise preparation in modern production lines – a combination of durability, hygiene, and industrial efficiency.

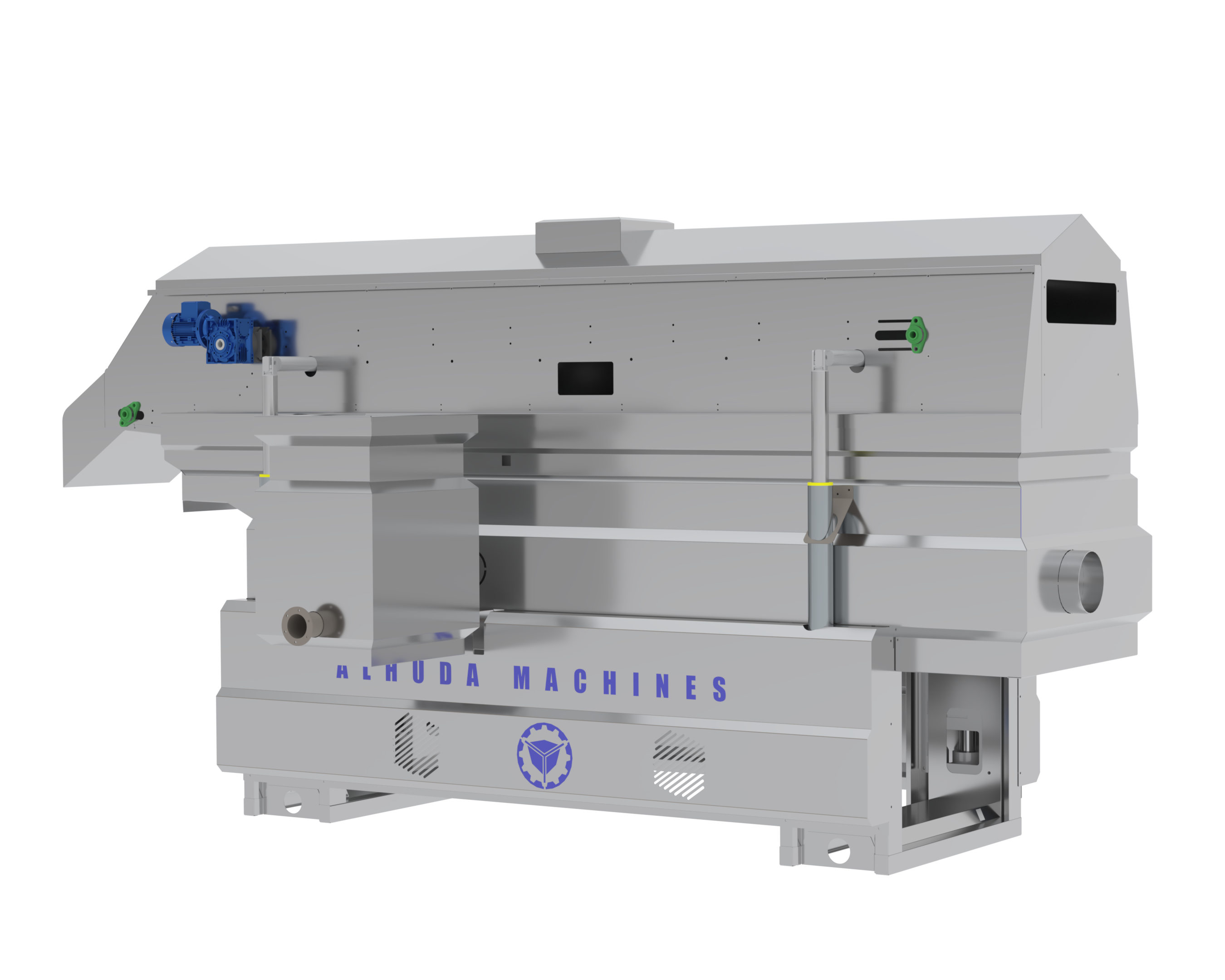

Flour coating and coating pan

The ideal solution for coating peanuts precisely and efficiently. The cylindrical coating mixer is a key component of any peanut coating production line. It uniformly coats the peanuts with liquid ingredients such as flour, flavorings, or sugar, in a hygienic, enclosed environment that ensures cleanliness and quality. The mixer is integrated with a conveyor belt to facilitate material movement during operation and increase production efficiency. Working Mechanism and Technical Features:

1️⃣ Hygienic cylindrical design made of food-grade 304 stainless steel. The mixer is entirely constructed from 304 stainless steel, which is resistant to heat and corrosion, making it ideal for the food industry where the highest standards of hygiene and durability are required.

2️⃣ Uniform coating function. The mixer precisely and evenly coats the peanuts through the continuous rotation of the cylindrical drum, distributing the liquid coating material uniformly over the entire surface of the peanuts. This process is essential for achieving a consistent final product in terms of appearance and taste.

3️⃣ Integrated conveyor belt for easy automatic transport. The mixer is equipped with a built-in conveyor belt that facilitates the loading and unloading of the peanuts, streamlining the production process and saving time and effort.

4️⃣ Dedicated discharge outlet for coated peanuts. The mixer features a bottom outlet that allows the coated peanuts to be discharged directly to the next stage of the production line (such as frying or drying).

5️⃣ Easy maintenance and cleaning. The mixer is designed for easy cleaning; the drum can be easily washed after each production batch. All internal surfaces are smooth and free of sharp corners to prevent residue buildup.

6️⃣ Energy-efficient performance: This mixer operates on 3.75 kW of electrical power, providing consistent and reliable performance 24/7. It can be equipped with an inverter to control the mixing speed according to the product type or coating viscosity.

Technical Specifications:

Material: Food-grade 304 stainless steel

Tank thickness: 2 mm

Power: 3.75 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 260 cm

Width: 150 cm

Height: 130 cm

Machine Number: 002

Model: THV-2025AL-T

Country of Origin: Turkey

Features of the Coating Mixer:

✔️ Hygienic design made of food-grade, rust-resistant stainless steel.

✔️ High capacity for evenly distributing the coating on the kernels.

✔️ Integrated conveyor belt for easy product transfer and reduced manual handling.

✔️ Bottom discharge for easy product removal.

✔️ Energy-efficient operation with continuous performance.

✔️ Easy to clean and maintain.

💡 This coating mixer is an essential piece of equipment for producing attractively coated peanuts with a balanced flavor and high-quality finish, meeting the demands of both local and international markets.

Vibrator for individualizing and feeding materials

The ideal solution for coating peanuts precisely and efficiently. The cylindrical coating mixer is a key component of any peanut coating production line. It uniformly coats the peanuts with liquid ingredients such as flour, flavorings, or sugar, in a hygienic, enclosed environment that ensures cleanliness and quality. The mixer is integrated with a conveyor belt to facilitate material movement during operation and increase production efficiency. Working Mechanism and Technical Features:

1️⃣ Hygienic cylindrical design made of food-grade 304 stainless steel. The mixer is entirely constructed from 304 stainless steel, which is resistant to heat and corrosion, making it ideal for the food industry where the highest standards of hygiene and durability are required.

2️⃣ Uniform coating function. The mixer precisely and evenly coats the peanuts through the continuous rotation of the cylindrical drum, distributing the liquid coating material uniformly over the entire surface of the peanuts. This process is essential for achieving a consistent final product in terms of appearance and taste.

3️⃣ Integrated conveyor belt for easy automatic transport. The mixer is equipped with a built-in conveyor belt that facilitates the loading and unloading of the peanuts, streamlining the production process and saving time and effort.

4️⃣ Dedicated discharge outlet for coated peanuts. The mixer features a bottom outlet that allows the coated peanuts to be discharged directly to the next stage of the production line (such as frying or drying).

5️⃣ Easy maintenance and cleaning. The mixer is designed for easy cleaning; the drum can be easily washed after each production batch. All internal surfaces are smooth and free of sharp corners to prevent residue buildup.

6️⃣ Energy-efficient performance: This mixer operates on 3.75 kW of electrical power, providing consistent and reliable performance 24/7. It can be equipped with an inverter to control the mixing speed according to the product type or coating viscosity.

Technical Specifications:

Material: Food-grade 304 stainless steel

Tank thickness: 2 mm

Power: 3.75 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 260 cm

Width: 150 cm

Height: 130 cm

Machine Number: 002

Model: THV-2025AL-T

Country of Origin: Turkey

Features of the Coating Mixer:

✔️ Hygienic design made of food-grade, rust-resistant stainless steel.

✔️ High capacity for evenly distributing the coating on the kernels.

✔️ Integrated conveyor belt for easy product transfer and reduced manual handling.

✔️ Bottom discharge for easy product removal.

✔️ Energy-efficient operation with continuous performance.

✔️ Easy to clean and maintain.

💡 This coating mixer is an essential piece of equipment for producing attractively coated peanuts with a balanced flavor and high-quality finish, meeting the demands of both local and international markets.

continuous fryer

High-tech design for consistent, 24-hour frying quality. This peanut roasting machine is specifically designed for efficient and continuous operation, meeting the demands of high-volume industrial production while maintaining superior quality. It ensures perfect roasting of the peanuts, while preserving the oil's properties and temperature throughout the day. Advanced operating mechanism:

1️⃣ Efficient oil heating via heat exchanger (indirect heating): The oil is heated outside the fryer by a heat exchanger (boiler), preventing oil burning and maintaining a consistent temperature. This system ensures: no change in oil properties; preservation of color and quality; and a stable frying process and final product quality.

2️⃣ Intelligent temperature and speed control: Equipped with a PID temperature control system that maintains a stable temperature throughout the frying process. The speed of the agitator and conveyor belt is controlled by frequency inverters for precise adjustment of the frying time.

3️⃣ Continuous stirring and complete peanut immersion: Continuous stirring ensures that all peanuts are evenly immersed in the hot oil, resulting in an ideal texture and flavor.

4️⃣ Smart safety system for emergencies: In case of electrical malfunction or power outage, the system automatically removes the peanuts from the fryer to prevent burning or damage.

5️⃣ Three-stage oil filtration system: The oil is continuously filtered during the frying process using: a three-stage filter to remove impurities; and a powerful 10,000 L/h pump for efficient oil circulation and filtration.

6️⃣ Integrated oil management system:

✅ Oil capacity: 400 liters ✅ A new (fresh) oil tank with a capacity of 400 liters, double-jacketed and equipped with heaters to maintain the oil temperature.

✅ A tank for recovering used oil, with the same capacity and also equipped with heaters.

✅ A system for draining used oil, easy to access and maintain.

7️⃣ Safe and environmentally friendly thermal design: The fryer is fully insulated with 12 cm thick fiberglass on all sides to ensure: heat loss prevention, protection of workers from contact with hot surfaces, and energy saving.

8️⃣ Hydraulic system for safely raising and lowering the moving part: The fryer is equipped with 4 hydraulic cylinders to ensure smooth and safe movement of the moving part during cleaning and maintenance.

9️⃣ Hygienic design that meets occupational safety standards: The fryer has two vents for steam and oil, preventing moisture buildup and maintaining a safe and clean working environment.

Technical Specifications:

Material: Food-grade stainless steel 304 and 310, resistant to high temperatures.

Electrical power: 11.75 kW | 380/220 V | 50 Hz

Number of motors: 8 motors with speed control inverters.

Dimensions: Length: 750 cm

Width: 120 cm

Height: 210 cm

Oil capacity: 400 liters

Machine number: 004

Model: THV-2025AL-T

Country of origin: Turkey

High-quality fryer components:

✔️ Inner oil tank: 5 mm thickness

✔️ Tank support profile: 15×15 cm | 5 mm thickness

✔️ Tank base: H-shaped steel beam | 10 mm thickness

✔️ Outer casing: Stainless steel | 3 mm thickness

✔️ Rotating drum (conveyor): 5 mm thickness

✔️ Main support frame: 10x10 cm chrome-plated profile | 5 mm thickness Features of the coated peanut roaster:

✔️ Indirect heating via a heat exchanger to maintain optimal oil quality.

✔️ Continuous stirring of the peanuts for even heat distribution.

✔️ Intelligent safety system for emergency situations.

✔️ Three-stage continuous oil filtration system.

✔️ Full thermal insulation for energy efficiency and worker safety.

✔️ Hygienic design that complies with industrial safety standards.

✔️ Suitable for continuous operation 24/7.

💡 The ideal solution for producing high-quality coated peanuts with exceptional operational efficiency, while protecting the environment and ensuring worker safety!

Conveyor line to OVEN

An essential link for the safe and smooth transport of peanuts to the roasting stage. The mesh conveyor belt is a vital piece of equipment in the peanut processing line. It transports the peanuts from the coating or frying station to the oven smoothly and consistently, while maintaining product integrity and quality. How it works and its features:

1️⃣ Safe and consistent transport: The mesh belt is specifically designed for efficient peanut transport, preventing clumping or spillage during movement and ensuring a continuous and uninterrupted production process.

2️⃣ Robust and durable construction of food-grade 304 stainless steel: The entire conveyor belt is made of 304 stainless steel, making it ideal for food applications, easy to clean, and corrosion-resistant.

3️⃣ Reliable and energy-efficient electric motor: The conveyor belt is powered by a 1.5 kW electric motor, providing sufficient power to operate the belt efficiently with low energy consumption.

4️⃣ Practical and easy-to-maintain design: The open-frame design allows easy access to the mechanical components, facilitating quick and easy routine maintenance, as well as easy cleaning of the conveyor belt.

Technical Specifications:

Material: Food-grade 304 stainless steel

Power: 1.5 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 300 cm

Width: 80 cm

Height: 180 cm

Machine Number: 005

Model: THV-2025AL-T

Country of Origin: Turkey

Features of the conveyor belt to the oven:

✔️ Continuous and consistent peanut transport without clumping or interruption.

✔️ A robust conveyor belt that withstands heat and humidity, protecting the product.

✔️ A corrosion-resistant, easy-to-clean frame.

✔️ A hygienic, safe, and easy-to-maintain design.

✔️ A reliable motor with low energy consumption.

💡 This conveyor belt ensures seamless integration between different stages of the production line, guaranteeing a smooth transfer of peanuts to the roasting stage without compromising their quality or integrity.

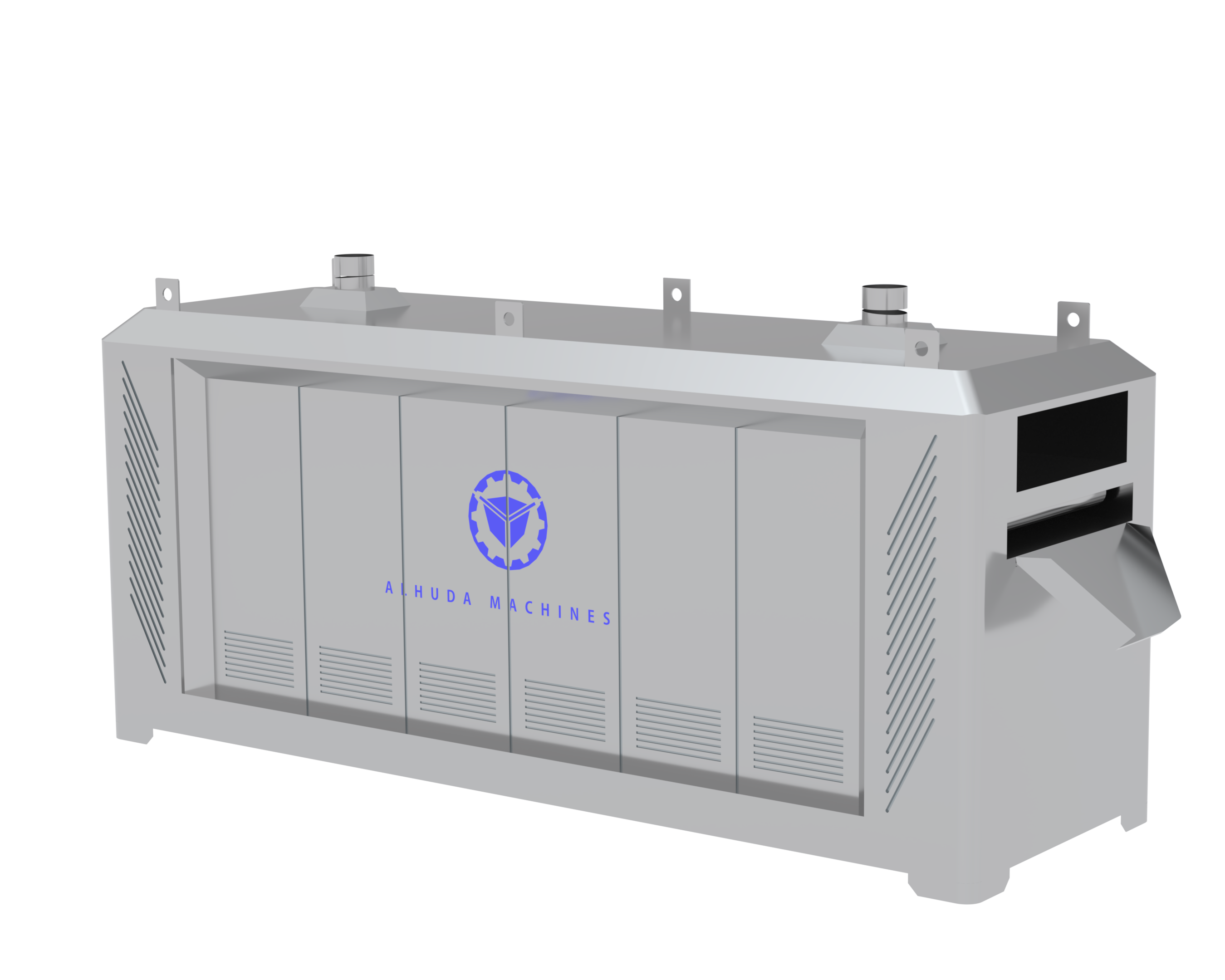

Roasting oven

Professional roasting with high quality and excellent production efficiency. The roasting oven is a key piece of equipment in peanut and nut processing lines. It roasts various types of nuts, such as peanuts, sunflower seeds, hazelnuts, almonds, pistachios, cashews, chickpeas, and more, using a hot air system that ensures even heat distribution for a consistently crisp and fresh high-quality product. Operating mechanism and technical features:

1️⃣ Hot air roasting system: The oven uses precisely distributed hot air to ensure even roasting of all nuts, preventing burning or uneven color and texture.

2️⃣ Excellent production capacity: The oven can produce 300 kg of roasted nuts per hour with consistent quality, making it suitable for medium to large-scale production lines.

3️⃣ Flexible fuel options: The oven can operate using either diesel or natural gas (LPG), providing flexibility to meet the customer's needs.

4️⃣ Automatic conveyor belt cleaning system: The oven is equipped with an automatic cleaning mechanism for the conveyor belt, maintaining cleanliness without frequent shutdowns.

5️⃣ Smart and precise control: Features a digital touchscreen for programming temperatures and full control of the oven. Includes programmable, accurate temperature sensors. Features an inverter for controlling the speed of the internal conveyor belt. Includes an automatic fault detection system that displays alerts as text messages on the screen.

6️⃣ Hot air circulation fans: These ensure even heat distribution within the roasting chamber and are controlled by inverters to guarantee optimal energy consumption.

7️⃣ Removable dual heating chambers: The oven is equipped with two integrated, removable heating chambers for easy maintenance.

8️⃣ Full thermal insulation: The oven is insulated on all sides with 12 cm of fiberglass to maintain internal temperature, reduce energy consumption, and protect operators.

9️⃣ Independent, removable control panel: The oven features an independent control panel with a separate, removable housing, facilitating installation, maintenance, and cleaning.

Technical Specifications: Material: Food-grade 304 stainless steel

Power: 9.75 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 650 cm

Width: 150 cm

Height: 200 cm

Machine Number: 006

Model: THV-2025AL-T

Country of Origin: Turkey

Features of the Roasting Oven:

✔️ Uniform, high-quality roasting using hot air.

✔️ High capacity suitable for medium and large-scale production.

✔️ Available with gas or diesel operation (optional).

✔️ Digital touchscreen with fault diagnostics.

✔️ Self-cleaning conveyor belt.

✔️ Removable and easily maintained dual heating chambers.

✔️ Fully insulated design for efficiency and safety.

✔️ Hygienic and easy-to-clean design, meeting the highest safety standards.

💡 The ideal solution for producing high-quality roasted nuts with a delicious taste and perfect texture, while ensuring excellent and reliable performance.

Conveyor belt for the product

Efficient peanut transfer after frying to the flavoring station for flavor distribution. The conveyor belt is a key component in the flavored peanut production line, transporting the fried peanuts from the fryer or cooling station to the flavoring machine, where they are coated with various flavors such as cheese, paprika, ketchup, and others. Working Mechanism and Technical Features:

1️⃣ Food-grade PVC conveyor belt: Made of food-grade PVC, resistant to oil, heat, and abrasion, making it ideal for transporting food products after frying.

2️⃣ 304 food-grade stainless steel frame: The entire conveyor frame is made of 304 food-grade stainless steel, which is rust-resistant and safe for food contact, ensuring easy cleaning and maintaining high hygiene standards in food processing plants.

3️⃣ Equipped with casters: The conveyor is fitted with swivel casters for easy movement within the facility for cleaning or rearranging, providing great operational flexibility.

4️⃣ High-efficiency electric motor: Equipped with a powerful electric motor with low energy consumption. It can be integrated into the main control system or operated independently.

Technical Specifications:

Material: 304 food-grade stainless steel

Conveyor belt: Food-grade PVC

Power: 1.125 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 200 cm

Width: 90 cm

Height: 120 cm

Machine Number: 007

Model: THV-2025 AL-T

Country of Origin: Turkey

Conveyor Belt Features:

✔️ Made of safe and durable food-grade PVC.

✔️ Stainless steel frame, resistant to oil and moisture.

✔️ Swivel wheels for easy movement and cleaning.

✔️ Suitable for use with peanut and nut processing lines.

✔️ Hygienic design that meets the highest quality and safety standards.

💡 The ideal solution for efficient product transport, offering ease of operation and cleaning, and flexibility for use in modern production lines.

Sorting and cooling vibrator

Cleaning and cooling peanuts after seasoning to ensure final quality. The sorting and cooling vibrator is an essential post-seasoning stage for peanuts. It removes excess seasoning, crumbs, and unwanted pieces, while simultaneously cooling the product before packaging, thus preserving its optimal texture and flavor. Mechanism and Technical Features:

1️⃣ Four-stage sorting and cleaning: The machine uses a four-stage, progressive vibration system to gradually sort the product, ensuring the removal of any remaining seasoning, small pieces, or other unwanted materials.

2️⃣ Effective cooling: During the vibration process, the product is naturally cooled through ventilation, preventing excess moisture and maintaining crispness and flavor, making it ready for immediate packaging.

3️⃣ Made of food-grade 304 stainless steel: The entire vibrator frame is made of corrosion-resistant, food-grade 304 stainless steel, ensuring easy cleaning and long-lasting durability.

4️⃣ Reliable electrical system: Equipped with a powerful motor and a 380/220V three-phase power supply, with adjustable vibration speed to suit the product type.

Technical Specifications:

Material: Food-grade 304 stainless steel

Number of vibration stages: 4 progressive stages

Power: 3.75 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 300 cm

Width: 90 cm

Height: 80 cm

Machine number: 008

Model: THV-2025 AL-T

Country of origin: Turkey

Features of the sorting and cooling vibrator:

✔️ Ensures precise removal of excess salt and flavors.

✔️ Sorts out unwanted pieces to maintain product quality.

✔️ Helps cool the peanuts before packaging.

✔️ Made entirely of food-grade, safe, and hygienic materials.

✔️ Practical, ergonomic design and easy maintenance.

💡 An ideal machine for preparing the final product to the highest quality, and an essential step in obtaining clean, seasoned, and chilled peanuts ready for packaging.

Flavoring device spice

A professional flavoring powder distribution system for perfectly coated peanuts and nuts. The flavoring powder coating machine is a crucial part of the production line, as it directly impacts the final taste and product quality. This machine precisely mixes, stirs, and distributes the flavoring powder to ensure a uniform coating on each peanut or nut.

Operating Mechanism and Technical Specifications:

1️⃣ Tank with integrated mixer: The machine features a food-grade 304 stainless steel tank with an internal mixer that continuously stirs the flavoring powder, preventing clumping and maintaining a consistent mixture.

2️⃣ Precise horizontal auger feeder: The flavoring powder is transported from the tank to the spray nozzle via a horizontal auger, ensuring a continuous and consistent flow of the required amount of flavoring.

3️⃣ Electronic control system and inverter: Equipped with an inverter for precise control of the flavoring flow rate, and a smart electronic control circuit for automatic adjustment of the distribution process according to the desired settings.

4️⃣ Highly precise spray system: The flavoring powder is sprayed onto the peanuts using a specially designed spray nozzle, ensuring even distribution without waste or clumping, resulting in perfectly flavored nuts.

Technical Specifications:

Material: Food-grade 304 stainless steel

Power: 2.25 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 190 cm

Width: 70 cm

Height: 100 cm

Machine Number: 009

Model: THV-2025 AL-T

Country of Origin: Turkey

Features of the Flavoring Powder Coating Machine:

✔️ Uniform distribution of flavoring powder across the entire product.

✔️ Continuous mixing to prevent clumping and ensure a consistent texture.

✔️ Precise inverter system for accurate flavor control.

✔️ Engineered to minimize waste and maximize efficiency.

✔️ Made entirely of food-grade, rust-resistant materials that are easy to clean.

💡 The ideal solution for producing peanuts or nuts with a consistent, appealing, and balanced flavor—exactly what consumers expect.

Flavor spray machine

The ideal system for coating peanut kernels with flavorings or other additives evenly. The flavoring machine is designed to ensure a uniform distribution of all flavors or other additives on the peanut kernels, thanks to a carefully designed movement mechanism that guarantees a consistent coating. This machine is essential for achieving the perfect taste of the final product.

Operating Mechanism and Technical Specifications:

1️⃣ Advanced bowl design: The machine features a specially designed flavoring bowl for mixing peanuts with salt, flavorings, or other additives. The peanuts are gently tumbled to ensure a uniform coating of flavor.

2️⃣ Reversible motor: The machine is equipped with a reversible motor, ensuring efficient and precise mixing, and allowing for easy emptying of the contents after the mixing process.

3️⃣ Continuous stirring and even distribution: The stirring process is continuous, guaranteeing that the peanuts are coated evenly and effectively with salt, flavorings, or other additives.

Technical Specifications:

Material: Food-grade 304 stainless steel

Power: 5.25 kW | 380/220 VAC | 50 Hz

Dimensions:

Length: 150 cm

Width: 120 cm

Height: 140 cm

Machine Number: 010

Model: THV-2025 AL-T

Country of Origin: Turkey

Features of the Flavoring Machine:

✔️ Uniform mixing of salt or other additives onto peanut kernels.

✔️ Reversible motor for efficient mixing and easy emptying.

✔️ Innovative pan design ensures even salt distribution.

✔️ Made from food-grade, rust-resistant material that is easy to clean.

💡 The perfect solution for preparing peanuts with a variety of flavors and seasonings, ensuring an even coating and enhancing their quality and taste.

Electrical parts and control panels

Circuit breakers: Schneider brand

Contactors: Schneider brand

Control panel: Delta

Inverters: Delta

Motors: GAMAK

Gearboxes: YILMAZ

Or as per customer request

basic information

🥜 Coated Fried Peanut Production Line – Crick Crack: Made in Turkey with German Technology – High Quality and Over 20 Years of Experience

🔹 Line Concept: The Crick Crack production line is a complete industrial system for manufacturing crispy, coated peanuts, commercially known as "Crick Crack."

The peanuts are prepared under the highest hygiene standards, coated with a flavored flour batter, precisely fried, and then coated with your preferred flavorings, resulting in a golden, crispy, and delicious product – ready for packaging and distribution.

⚙️ Main Process Stages:

1. ✅ Peanuts Cleaning and Screening: Removing impurities and foreign objects using specialized equipment to obtain clean, ready-to-process peanuts.

2. ✅ Pre-Roasting (Optional): Improves flavor and prepares the peanuts for the coating process.

3. ✅ Batter Coating Mixer: The peanuts are mixed with a flour, water, and spice batter in a rotating mixer, ensuring each peanut is evenly coated.

4. ✅ Initial Coating Drying: An air dryer is used to set the outer coating before frying.

5. ✅ Automatic Oil Fryer: Precisely fries the peanuts to achieve a golden color and crispy texture without excessive oil absorption.

6. ✅ De-Oiling System: Removes excess oil through vibration or centrifugation to maintain the product's freshness and crispiness.

7. ✅ Flavoring Drum: Sprays various flavors such as cheese, paprika, ketchup, chili, and more – according to customer preference.

8. ✅ Cooling Machine: Cools the product before packaging to maintain crispness and ensure proper packaging integrity. 9. ✅ Packaging: The product is packaged in high-quality bags or containers, ready for distribution.

🏭 Technical Specifications and Required Space:

🔸 Total Line Length: 22 meters

🔸 Width: 3 meters

🔸 Required Operating Area: 250–300 square meters

🔸 Materials Used: Food-grade, rust-resistant 304 stainless steel

🔸 Country of Origin: Turkey – German design and technology

🔸 Line Testing and Commissioning: Performed at Al Huda Company's factory – Gaziantep, Turkey

🎯 Line Features: High-quality, crispy finished product with excellent consistency. Ability to produce multiple flavors. Automatic operation, easy maintenance. Full warranty on the entire line. Ongoing technical support and after-sales service.

📩 For Inquiries and Price Quotes: To learn more about the line, its production capacity, and customization options, please contact us.

🛡️ Al Huda – Generations of experience in the industry, and continuous innovation for the future. Al Huda is your ideal choice… and your partner for success.

Gallery