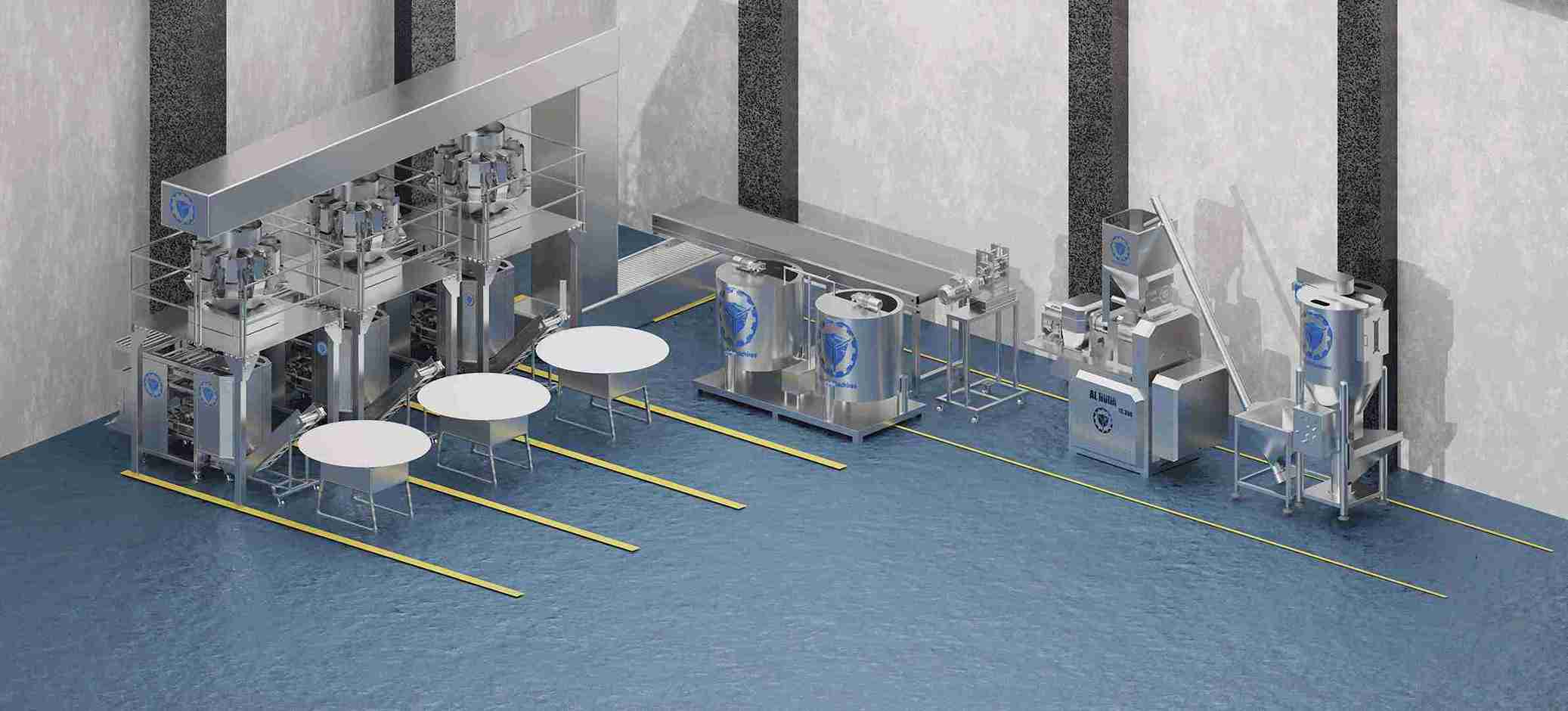

chocolate stuffed corn chips production line

🍫🌽 Chocolate Stuffed Corn Chips Production Line An innovative production line used to produce crunchy, hollow corn chips, then filled with chocolate or various creams such as vanilla, hazelnut, or strawberry.

✅ Brief working mechanism:

1️⃣ Made from corn.

2️⃣ Extrusion: The corn is formed into hollow fingers using a special extrusion machine.

3️⃣ Filling: Chocolate is precisely injected into the fingers.

4️⃣ Cooling: The product is cooled before packaging to preserve its texture and taste.

5️⃣ Packaging: The fingers are packaged in airtight bags to maintain their quality.

✨ Line Features: An innovative product that is very popular with children. Oil-free (oven-baked, not fried). A delicious taste that combines crunchiness with a chocolate filling. The filling can be changed upon request (chocolate, vanilla, strawberry).

The line consists of the following parts

1 – Corn Moisturizing Mixer // 400 kg capacity //

2 – Spiral Feeder

3 – Extruder (blasting and shaping head) with automatic feeding device

4 – Two Chip Finger Cutter

5 – Product receiving conveyor from the cutter

6 – Chocolate cooking tank convector

7 – Chocolate softener

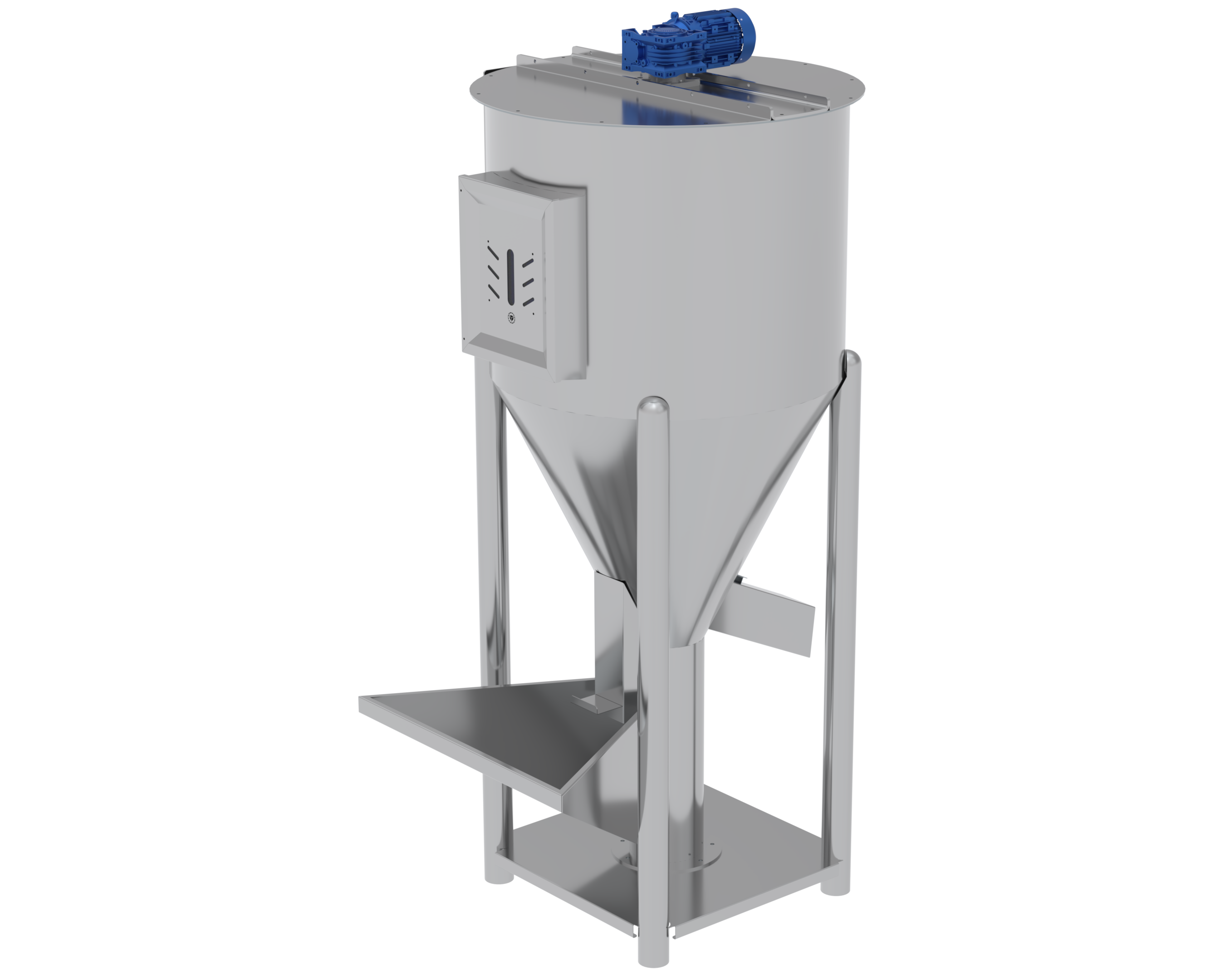

Corn mixer

Homogeneous mixing and precise moisture control – Hygienic design and reliable performance! This mixer is used in the corn preparation stage before shaping or frying. It homogeneously mixes the corn while controlling the desired moisture content, contributing to improved product quality. The mixer features a sturdy body made entirely of food-grade 304 stainless steel, with a design that takes into account safety, ease of operation, and maintenance.

⚙️ Working mechanism:

1️⃣ Homogeneous mixing of corn

✔️ Equipped with a powerful 5-horsepower Turkish-made main motor, ensuring efficient rotation and homogeneous mixing of materials.

2️⃣ Corn moisture control

✔️ Includes a dedicated water tank to control the moisture content, with a water level indicator.

3️⃣ Safety and ease of use

✔️ Equipped with mechanical protection (metal mesh) to prevent operators from entering the mixer.

✔️ Includes a standard drain hole, as well as a monitoring and cleaning hole.

4️⃣ Removing Impurities

✔️ The blender bowl is equipped with a magnet to remove any metal impurities from the corn.

5️⃣ Hygienic Materials

✔️ The blender is made entirely of 2mm thick, food-grade 304 stainless steel to ensure hygiene and long-lasting durability.

📏 Technical Specifications:

✅ Machine Type: Industrial Corn Mixer

✅ Capacity: 400 kg

✅ Material Type: 304 food grade stainless steel – 2 mm thick

✅ Motor: 5 HP – Made in Turkey

✅ Electric Power: 3.75 kW

✅ Voltage: 380/220 VAC – 50 Hz

✅ Dimensions:

✔️ Length: 180 cm

✔️ Width: 120 cm

✔️ Height: 230 cm

✅ Machine Number: 001

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey

💡 Why is this mixer an essential component in corn processing?

✔️ Because it ensures homogeneous mixing and optimal moisture control.

✔️ Because it is made of hygienic, safe, and easy-to-clean materials.

✔️ Because it is equipped with safety and operator comfort systems.

✔️ Because it contributes to raising the quality of the final product and improving the performance of the production line.

Screw conveyor

Precise automatic feeding with a hygienic and safe design! The screw conveyor is used to automatically and consistently feed materials (such as corn) into the extruder, ensuring continuous operation and consistent production, while adhering to hygiene and food safety standards. It features a robust design made of 304 food-grade stainless steel, with mechanical and magnetic protection to ensure safe operation and product quality.

⚙️ Working Mechanism:

1️⃣ Automatic Extruder Feeding

✔️ It has a 100 kg capacity tank that automatically and evenly feeds materials into the extruder.

2️⃣ Hygienic and Safe Design

✔️ The tank and body are made of 2 mm thick 304 food-grade stainless steel.

✔️ It has a bottom opening for cleaning, allowing for easy maintenance and cleaning.

3️⃣ Operator Protection and Product Quality

✔️ It has a mechanical guard (metal mesh) to prevent the operator's hand from entering the mixer during operation.

✔️ It has a special magnetic mechanism to remove metal impurities from the incoming material.

📏 Technical Specifications:

✅ Device Type: Spiral Conveyor for Extruder Feeding

✅ Capacity: 100 kg

✅ Material Type: Food-grade 304 stainless steel - 2 mm thick

✅ Protection System: Mechanical Protection + Magnetic for Metal Impurity Removal

✅ Voltage: 380/220 VAC - 50 Hz

✅ Power: 1.25 kW

✅ Dimensions:

✔️ Length: 350 cm

✔️ Width: 100 cm

✔️ Height: 300 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey

💡 Why is this spiral conveyor an essential part of the production line?

✔️ Because it ensures consistent automatic feeding to the extruder.

✔️ Because it is made of hygienic and easy-to-clean materials.

✔️ Because it is equipped with effective protection systems to ensure worker and product safety.

✔️ Because it helps improve the continuity and efficiency of the production line.

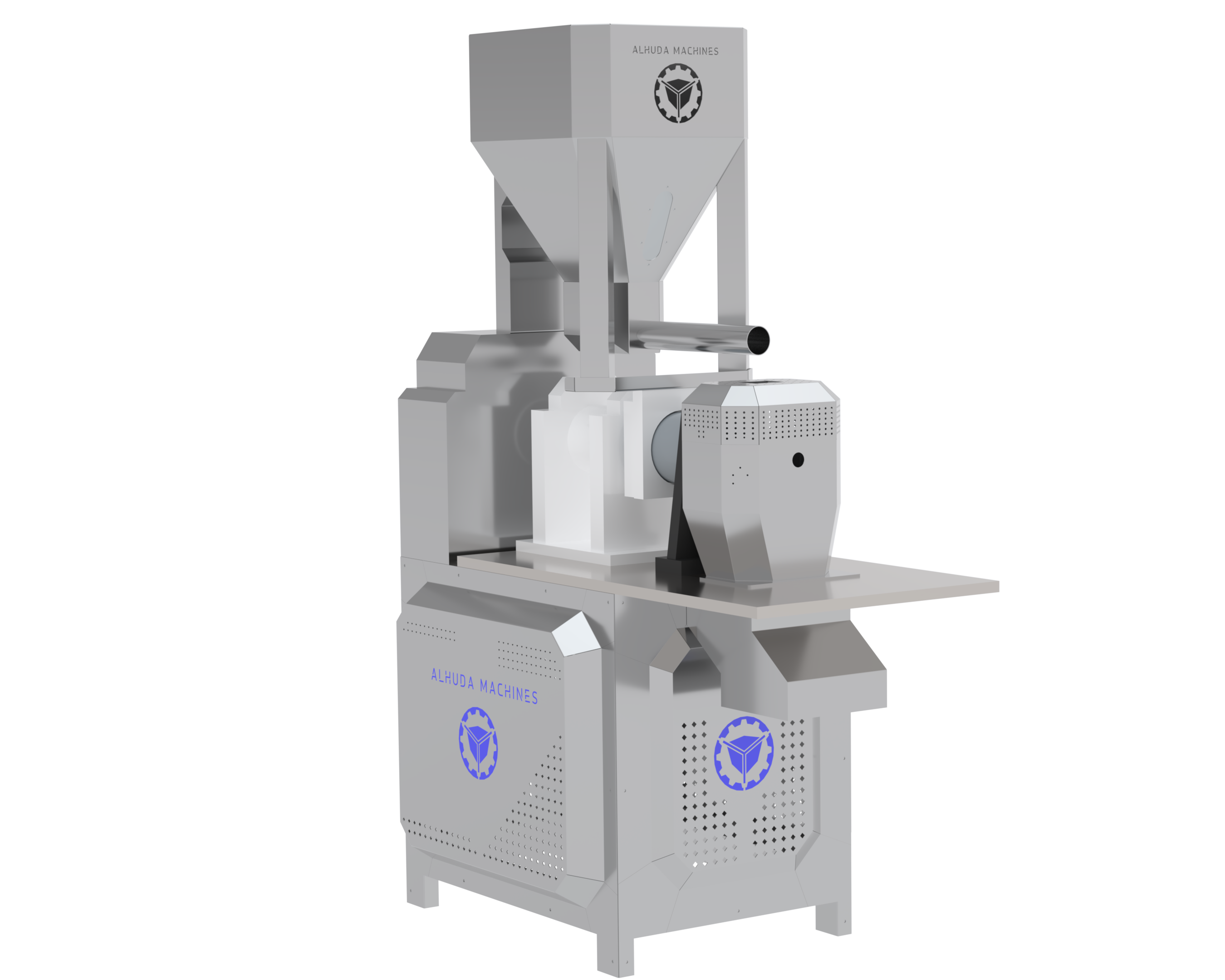

Chocolate Stuffed Corn Chips Extruder

Sürekli üretim ve yüksek kalitede doldurulmuş mısır çekirdeği şekillendirme - profesyonel endüstriyel tasarım ve eşsiz performans! Bu ekstruder çikolatalı mısır cipsi üretmek için kullanılır. Sürekli ve hassas çalışmayı garanti altına almak için yüksek üretim kapasitesi, sağlam yapı ve ileri teknolojiye sahiptir. En yüksek endüstriyel performans standartlarını karşılayacak şekilde tasarlanan bu cihaz, akıllı kontrol paneli ve dayanıklı, yüksek kaliteli malzemelerden üretilen gövdesiyle tüm fonksiyonların tamamen elektronik olarak kontrol edilmesini sağlıyor.

⚙️ Etki mekanizması:

1️⃣ Doldurulmuş tahılın hassas bir şekilde şekillendirilmesi

✔️ İstenilen tane şekline bağlı olarak 175 ile 200 kg/saat arasında üretim kapasitesi ile çalışmaktadır.

✔️ Tanenin uzunluğu elektronik değişken hızlı bıçak (invertör) ile kontrol edilir.

2️⃣ Güçlü mekanik yapı

✔️ Ana sehpa ısıl işlemli çelikten, ayaklar ise Continuous production and high-quality filling of stuffed corn kernels – Professional industrial design and unparalleled performance! This extruder is used to form chocolate-filled corn kernels. It features high production capacity, a robust construction, and advanced technology that ensures continuous and precise operation. Designed to meet the highest industrial performance standards, it features fully electronic control of all functions via an intelligent control panel and a frame made of resistant, high-quality materials.

⚙️ Working mechanism:

1️⃣ Precise filling of the kernel

✔️ Operates at a production capacity ranging from 175 to 200 kg/hour, depending on the desired kernel shape.

✔️ The kernel length is controlled by an electronic variable-speed inverter.

2️⃣ Robust mechanical structure

✔️ The main carrier is made of heat-coated steel, with standard steel legs.

✔️ The extruder is insulated with a 304 food-grade stainless steel outer layer for easy cleaning.

✔️ Approximate weight: 1300 kg.

3️⃣ Advanced screw system

✔️ Screws are made of premium metals, treated using vacuum furnace technology.

✔️ Equipped with a main screw to feed the compressor screw, with speed control via an inverter.

✔️ 50 hp / 35 kW compressor screw motor, made in Turkey or Italy, with premium copper windings.

4️⃣ Professional gearbox

✔️ American Extrusion main gearbox, designed to withstand 24-hour continuous operation.

✔️ SKF bearings and bearings – Swedish and Japanese.

5️⃣ Efficient cooling and heating

✔️ Equipped with a start-up heater, electronically controlled via a temperature gauge.

✔️ Dual cooling system: closed-circuit water cooling + air cooling, ensuring stable operating temperatures.

6️⃣ Advanced Control Panel

✔️ Independent control panel made of 304 stainless steel, with a special ventilation system for hot environments.

✔️ Equipped with 3 ventilation filters + 3 cooling fans + dust protection.

✔️ Equipped with a classic control panel for complete control.

✔️ Automatic fault reading system + automatic program storage + detailed electrical diagram.

✔️ Equipped with wheels for easy movement and cleaning.

📏 Technical Specifications:

✅ Machine Type: Chocolate-Filled Corn Chips Extruder

✅ Production Capacity: 175 to 200 kg/hour, depending on the grain shape

✅ Material: 304 food-grade stainless steel outer frame

✅ Cooling System: Closed-Circuit Water Cooling + Air Cooling

✅ Number of Inverters: 3 Speed Controllers

✅ Main Motor: 50 HP (35 kW) - Turkish or Italian Made with Copper Coils

✅ Electrical Voltage: 380/220 VAC - 50 Hz

✅ Electrical Power: 39.75 kW

✅ Dimensions:

✔️ Length: 180 cm

✔️ Width: 120 cm

✔️ Height: 240 cm

✅ Machine Number: 003

✅ Model: THV-2025PV-Z

✅ Country of Origin: Türkiye

💡 Why is this? Is the extruder the ideal choice for producing chocolate-filled corn chips?

✔️ Because it operates at high, continuous production capacity.

✔️ Because it allows precise control over the length and shape of the kernel.

✔️ Because it is designed from durable, easy-to-clean materials.

✔️ Because it provides an efficient cooling and heating system that maintains product stability.

✔️ Because it is equipped with an intelligent control panel and an integrated protection system to ensure optimal industrial performance.

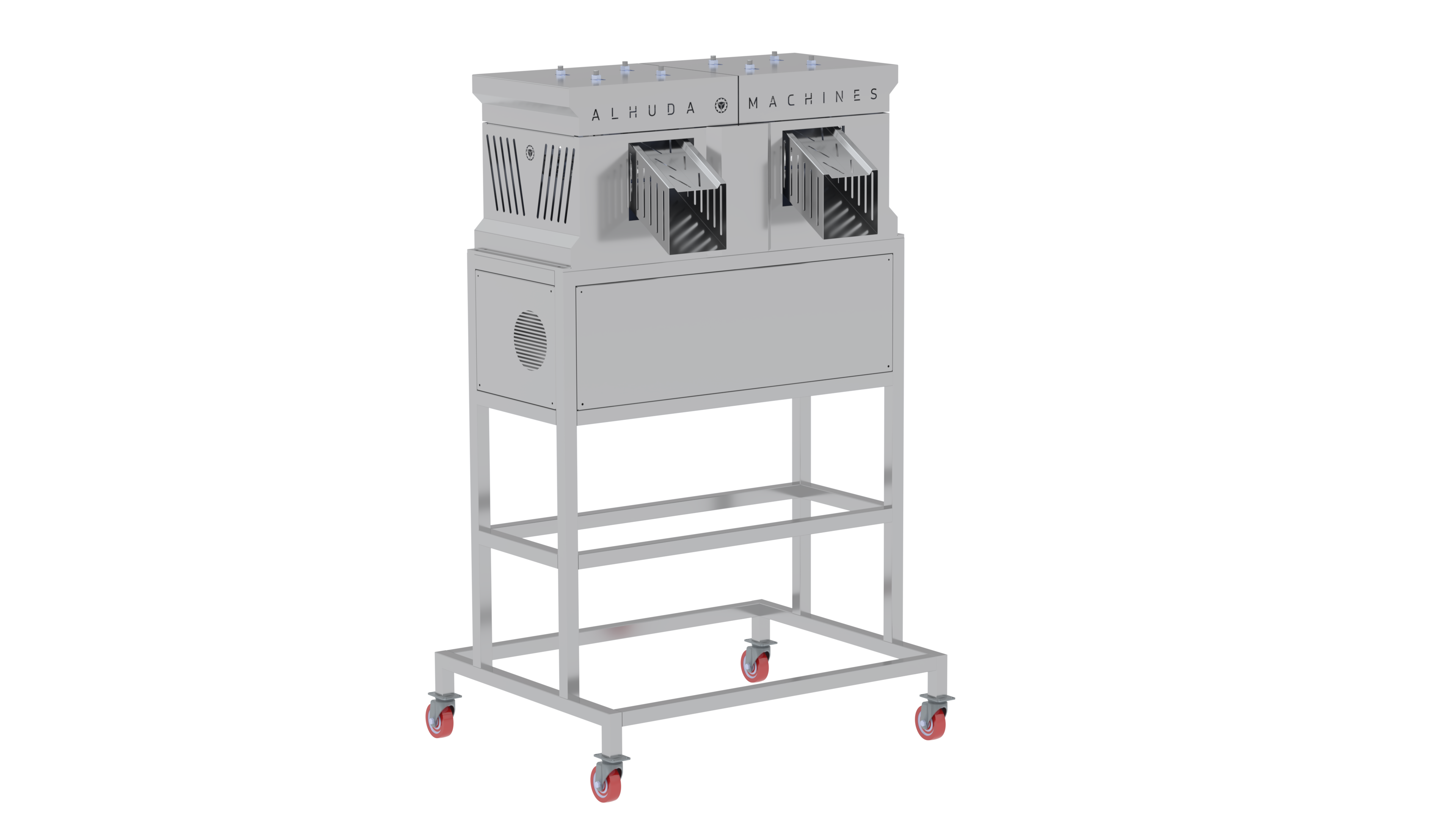

Potato fingers slicer

Perfect control of chip length – precise cutting and quality design! This cutter is used in the post-forming stage, cutting corn chips (puffs) to the desired length with precision and smoothness. It features electronic kernel length adjustment via an inverter, making it ideal for meeting various production requirements.

⚙️ Working mechanism:

1️⃣ Adjustable precision slicing

✔️ The cutter speed is electronically controlled via an inverter.

✔️ The kernel length can be set from 2 cm to 15 cm with high precision.

2️⃣ Hygienic and durable design

✔️ The outer body is made entirely of food-grade 304 stainless steel, ensuring product safety and easy cleaning.

📏 Technical Specifications:

✅ Device Type: Corn Chips Cutter

✅ Cutting Mechanism: Motorized with Inverter for Length Adjustment

✅ Adjustable Length: From 2 cm to 15 cm

✅ Material: Food-grade 304 stainless steel

✅ Voltage: 380/220 VAC – 50 Hz

✅ Power: 1.25 kW

✅ Dimensions:

✔️ Length: 120 cm

✔️ Width: 90 cm

✔️ Height: 150 cm

✅ Machine Number: 004

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey

💡 Why choose this cutter for your production line?

✔️ Because it offers flexible control of grain length as required.

✔️ Because it is made of hygienic materials suitable for the food industry.

✔️ Because it is easy to operate and clean and suitable for continuous work in production lines

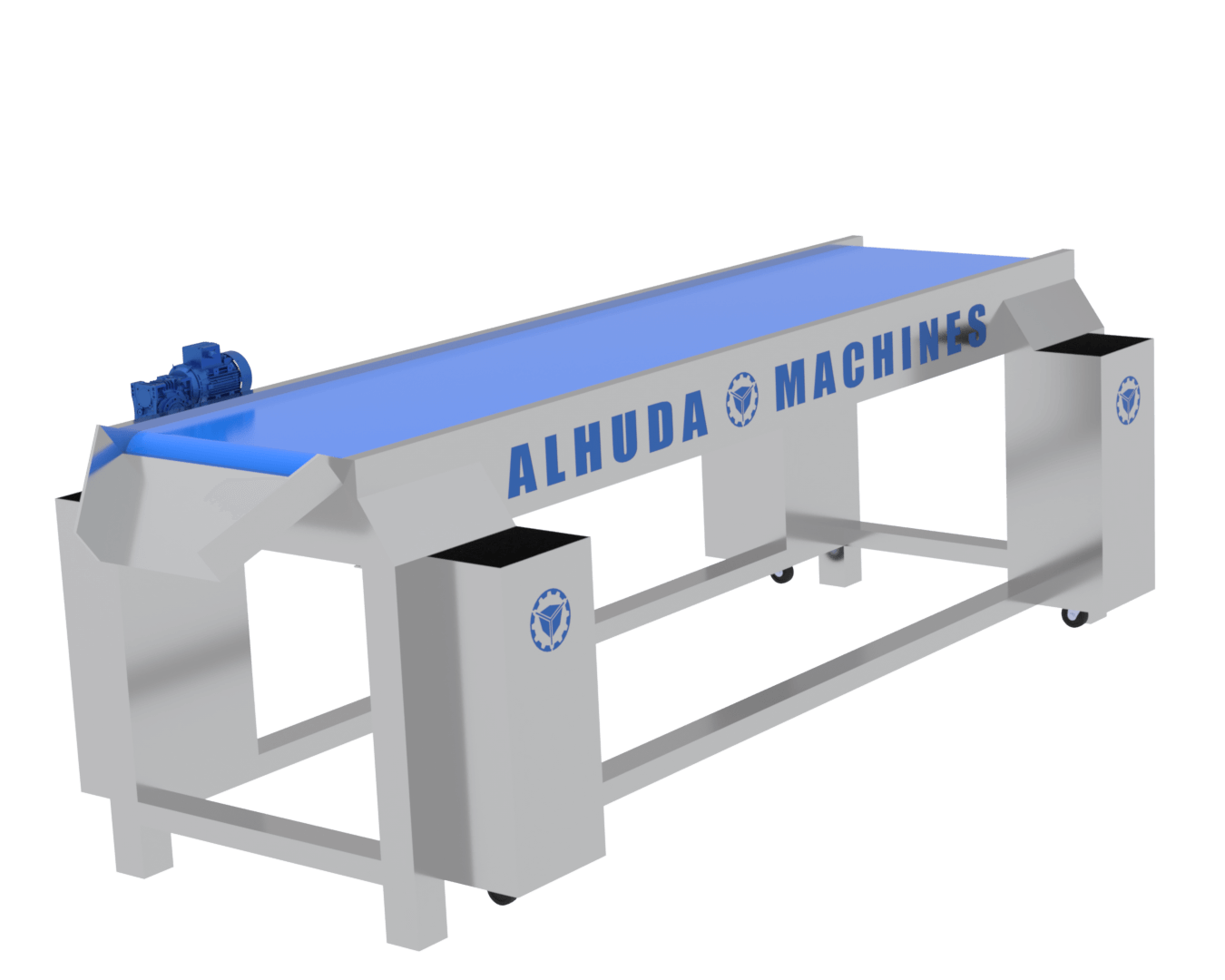

Conveyor belt for the product

Smooth Receiving and Transporting Chip Sticks – Cleanliness and Efficiency at Every Step! This conveyor belt is used in the post-slicing stage, receiving corn chips (stuffed or unstuffed) coming from the cutter. It helps transport and distribute them smoothly and evenly throughout the production line, ensuring smooth and stable product movement.

⚙️ How It Works:

1️⃣ Product Receiving After Cutting

✔️ The line receives the chips directly from the cutter and regulates their movement on the conveyor.

2️⃣ Hygienic and Efficient Conveyor Belt

✔️ The conveyor is made of food-grade PVC or food-grade plastic to ensure hygienic and safe transportation of the chips.

3️⃣ Easy to Move and Clean

✔️ Equipped with wheels for easy movement and cleaning after use.

✔️ It includes automatic cleaning brushes to keep the conveyor clean during operation.

4️⃣ Fully Hygienic Design

✔️ The overall frame is made of 304 food-grade stainless steel, ensuring rust resistance and easy washing.

📏 Technical Specifications:

✅ Machine Type: Conveyor for Chips

✅ Belt: PVC or food-grade plastic

✅ Cleaning System: Automatic cleaning brushes

✅ Equipped with moving wheels

✅ Material: 304 food-grade stainless steel

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

✔️ Length: 400 cm

✔️ Width: 80 cm

✔️ Height: 200 cm

✅ Machine Number: 005

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey

💡 Why is this conveyor necessary in a production line?

✔️ Because it ensures consistent and convenient handling of chips after cutting.

✔️ Because it provides a clean and safe transport surface thanks to the cleaning brushes.

✔️ Because it's easy to move and wash thanks to its smart design and practical wheels.

1/Kong - Chocolate cooking tank

Two integrated solutions for preparing melted chocolate with the highest quality and thermal efficiency! First, the Kong Chocolate Cooker: A professional double-jacket device for melting and grinding chocolate smoothly, equipped with a mixer, internal circulation pump, and metal balls to improve consistency and quality.

⚙️ Technical Specifications – Cooking Unit:

✅ Capacity: 600 kg

✅ Design: Double-walled (Double Jacket) for hot water filling

✅ Heating: Electronically temperature-controlled electric heaters

✅ Chocolate Circulation: Internal pump lifts chocolate from the bottom to the top for better grinding

✅ Grinding: Metal balls inside the tank

✅ Cooling: Double jacket with pump to accelerate water circulation inside the jacket

✅ Walls: Inner wall thickness: 8 mm, Outer wall thickness: 4 mm, Tank floor thickness: 15 mm

✅ Equipped with an electric control panel. Second – Chocolate Comfort Tank (Fanner): A tank designed to maintain the fluidity of chocolate and prevent it from solidifying, thanks to a double-walled heating system and precise electronic control.

⚙️ Technical Specifications – Comfort Tank:

✅ Capacity: 600 kg

✅ Design: Double Jacket for Hot Water Heating

✅ Heating: Electric Heaters with Electronic Control

✅ Hot Water Circulation: Built-in Pump

✅ Walls: Inner Wall Thickness: 4 mm, Outer Wall Thickness: 4 mm, Floor Thickness: 6 mm

✅ Material: Food-grade 304 stainless steel

✅ Equipped with an electric control panel

✅ Voltage: 380/220 VAC – 50 Hz

✅ Power: 10.5 kW

✅ Dimensions:

✔️ Length: 180 cm

✔️ Width: 120 cm

✔️ Height: 170 cm

✅ Machine Number: 006

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey

💡 Why is this system ideal?

✔️ Maintains the quality and smoothness of the chocolate throughout the process.

✔️ Easy to clean and maintain thanks to its hygienic design.

✔️ Precise temperature control to prevent clumping or burning.

✔️ Integrated cooking and ergonomic units provide smoothness and stability in the production line.

Electrical parts and control panels

Schneider breakers

Schneider contactors

Delta control panel

Delta inverters

Gamak motors

Yilmaz gearboxes

Or as per customer request

basic information

🍫🌽 A state-of-the-art production line for chocolate-filled corn chip sticks: Innovative technology for producing a unique snack that combines the crunchiness of corn with the smoothness of chocolate!

🔹 Overview: The chocolate-filled corn chip stick production line is one of the most innovative in the modern snack food industry, combining the crispiness of corn sticks with the deliciousness of a melted chocolate filling. This product reflects current market trends towards creating snacks that offer a combination of texture, flavor, and nutritional value, and is extremely popular with children and teenagers. ⚙️ Production Line Stages:

1️⃣ Corn Mixer – Unit 001

🔹 High-efficiency mixer with a 400 kg capacity

🔹 Precisely mixes semolina, water, and flavorings

🔹 Made of food-grade 304 stainless steel

🔹 Equipped with a water tank and a level indicator for moisture control

🔹 Features a magnet to remove metal impurities

🔹 Powerful 5 HP motor

2️⃣ Screw Conveyor – Unit 002

🔹 Transports materials from the mixer to the extruder

🔹 100 kg hopper capacity

🔹 Continuous automatic feeding

🔹 Equipped with a safety mesh and an additional magnet

3️⃣ Extruder – Unit 003

🔹 The heart of the line, responsible for shaping the hollow, crispy corn snacks

🔹 Output: 175–200 kg/hour

🔹 Electronic control of snack length and cutting speed

🔹 Equipped with cooling systems (air + water)

🔹 Rotating knives for cutting the snacks

🔹 3 inverters for complete control of motor speeds

4️⃣ Snack Cutter – Unit 004

🔹 Controls the length of the snacks (from 2 cm to 15 cm)

🔹 Made of 304 stainless steel

🔹 Equipped with an inverter for precise speed control

5️⃣ Product Conveyor Belt – Unit 005

🔹 Transports the cut snacks to the next stages

🔹 Maintains Arranges the corn sticks and helps them cool down

🔹 Features an automatic cleaning brush

🔹 Food-grade PVC conveyor belt

🔹 Easy to move and clean thanks to the wheels

6️⃣ Chocolate Melting and Holding Tank – Model 006

🔹 Prepares the chocolate for filling into the corn sticks

🔹 Tank: 600 kg capacity, with grinding balls and a double-jacketed heating system

🔹 Holding tank: Maintains a consistent chocolate temperature

🔹 Electronic temperature control system

📐 Dimensions and Required Space:

🔸 Total line length: approximately 12 meters

🔸 Required width: approximately 4 meters

🔸 Total required area: approximately 200 square meters

🌟 General Features of the Line:

✅ Fully hygienic design made of food-grade 304 stainless steel

✅ Fully automated operation system

✅ Advanced electronic control with inverter systems and full programming

✅ High safety for operators with safety nets and protective covers

✅ Easy maintenance and cleaning

✅ High energy efficiency and continuous production

🍫 Final Product: Chocolate-filled corn chips – A unique product combining a crispy outer layer with a rich, melted chocolate filling. Available in various shapes and lengths, packaged in sealed bags or individual wrappers, depending on market needs.

Gallery