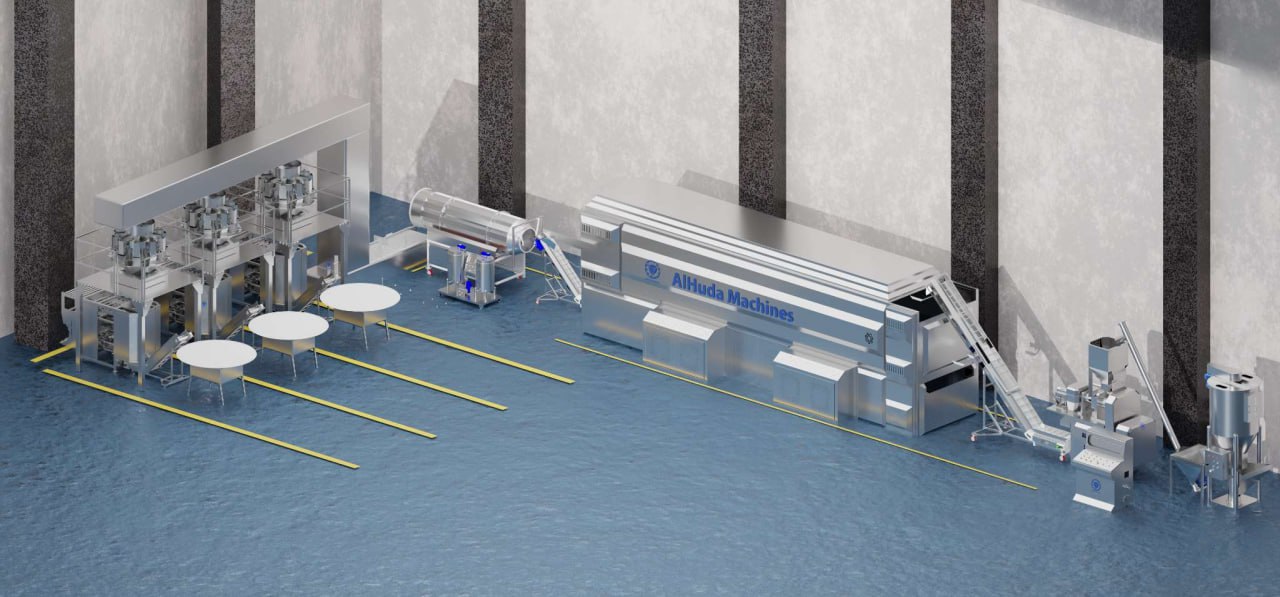

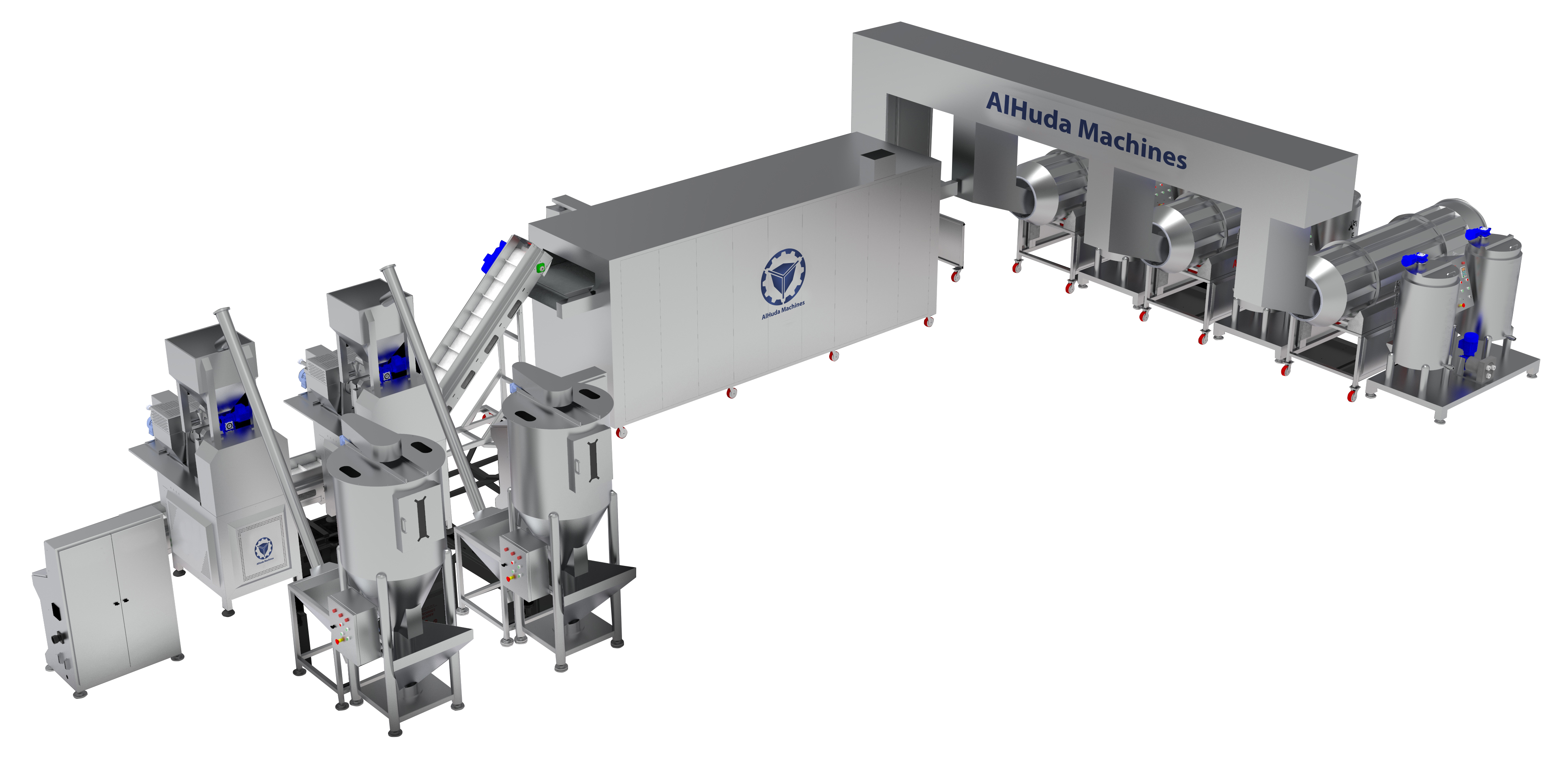

A fully automated corn chips production line that includes three filling and wrapping machines and a weighing system with a production capacity of 200 kg.

🌽 Automatic Corn Chips Production Line – Clean, Hand-Free Production This line is used to produce corn chips (puffs or snacks) completely without any manual intervention.

The process begins with mixing the corn flour, then shaping it inside an extruder. It is then dried, flavored, and automatically packaged into bags.

✅ The line operates fully automatically – from the beginning of production to packaging.

✅ Complete hygiene and high quality – no human contact is required during production.

✅ Designed according to global health standards – ideal for modern factories.

✅ Easy and fast production – with just the push of a button, operation begins.

The line consists of the following parts

1. Corn mixer

2. Spiral conveyor

3. Extruder

4. Product conveyor belt

5. Hot air broiler

6. Flavor mixing tank assembly

7. Flavor pump

8. Seasoning cylinder

9. Line for feeding filling machines

10. Packaging machines

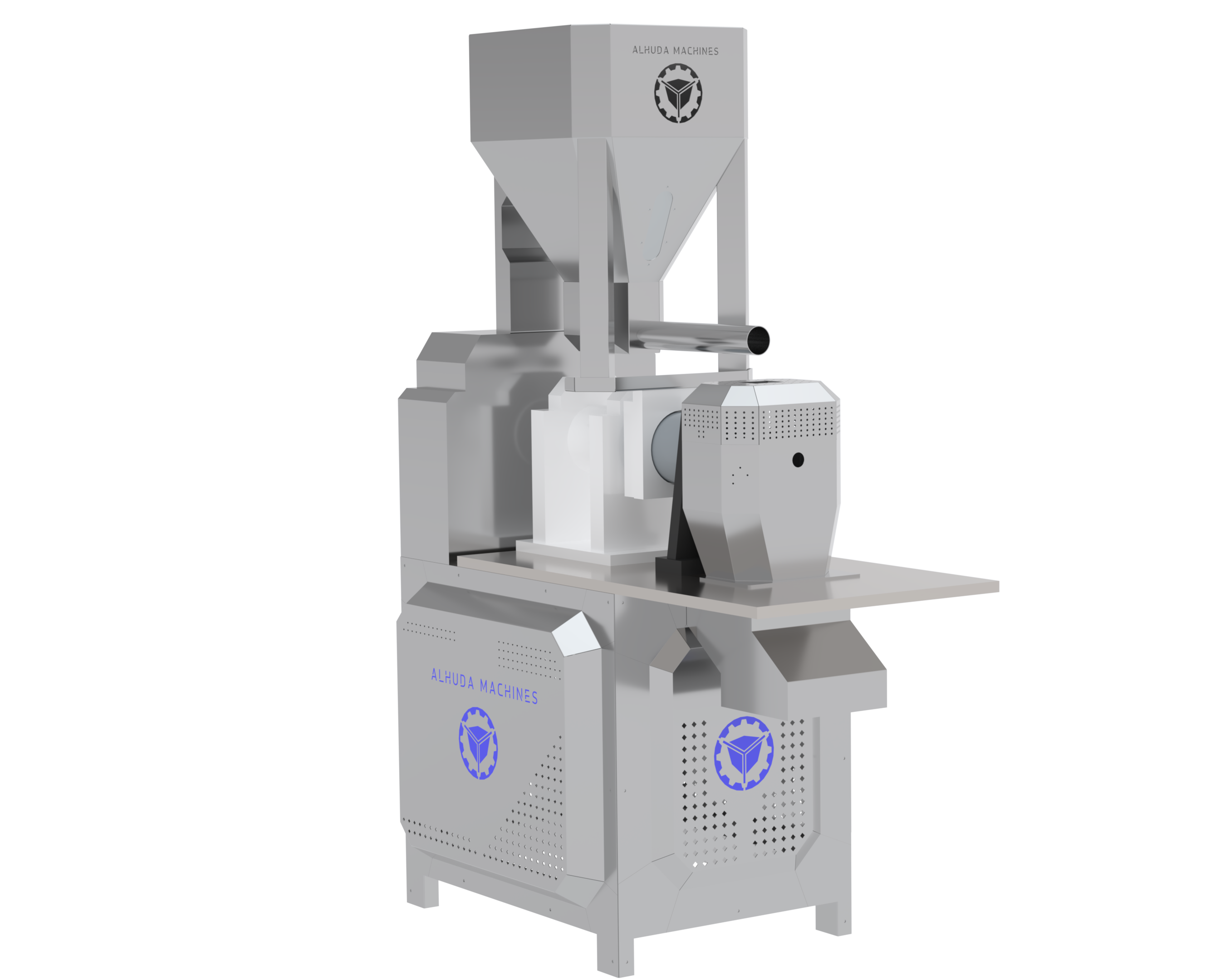

Corn mixer

Homogeneous and precise mixing of corn to the highest quality standards. The corn mixer is an essential piece of equipment for preparing corn before the manufacturing process. It achieves perfect homogeneity in the corn mixture by adding the precise moisture content, ensuring even distribution and professional preparation of the final product. Advanced Operation Mechanism

1️⃣ Large capacity and high-quality manufacturing materials. Capacity: 400 kg, allowing for efficient processing of large quantities of corn. Material: Made entirely of 2 mm thick food-grade 304 stainless steel, ensuring rust resistance and maintaining product hygiene.

2️⃣ Powerful motor to ensure perfect mixing. Main motor: 5 HP, Turkish-made, ensuring stable performance and high mixing efficiency. A homogeneous mixing mechanism ensures optimal distribution of ingredients within the mixer.

3️⃣ Precise moisture control. Equipped with a built-in water tank, it allows for precise control of the corn moisture content to achieve the desired consistency. A water level indicator helps accurately adjust the quantity during the mixing process.

4️⃣ A high-security worker safety system equipped with mechanical protection (metal mesh) that prevents workers from entering the mixer during operation, ensuring a safe working environment.

5️⃣ A smooth unloading and process control system equipped with a standard unloading port that allows easy product removal without clumping or loss of raw materials. Equipped with a monitoring and cleaning port, this allows for monitoring the mixing process and ensuring the cleanliness of the mixer after each use.

6️⃣ Effective removal of metal impurities: The mixer basin contains a powerful magnet that removes any metal impurities from the corn, ensuring the purity of the final product and preventing unwanted materials from entering subsequent production lines. Technical Specifications: ✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Electrical Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 180 cm

Width: 120 cm

Height: 230 cm

✅ Machine Number: 001

✅ Model: THV-2025PV-Z

✅ Country of Manufacture: Turkey – High-quality manufacturing according to European standards. Durable construction and high-efficiency performance.

✔️ 2 mm thick interior design for corrosion resistance and long-lasting durability.

✔️ Smooth discharge system allows easy control of the corn extraction process after mixing.

✔️ High mechanical protection to ensure worker safety during operation.

✔️ Magnets inside the tub to remove any metal impurities that may affect product quality.

✔️ Precise control of corn moisture through a built-in water tank and level indicator.

✔️ Robust and durable design made entirely of food-grade 304 stainless steel to ensure maximum hygiene.

✔️ High-security system with a metal mesh to prevent hand entry during operation.

✔️ Effective removal of metal impurities using the built-in magnet in the tub.

✔️ Easy emptying and cleaning via dedicated holes.

✔️ High-performance motor to ensure optimal mixing efficiency and highest quality.

💡 The perfect solution to ensure homogeneous mixing and professional preparation of corn with the best quality and operational efficiency!

Screw conveyor

Precise, efficient, and safe automated material conveying. The spiral conveyor is one of the most important pieces of equipment in production lines. It automatically feeds materials into the extruder in a smooth and efficient manner, ensuring a consistent flow and improving production efficiency with the highest levels of safety and quality. Advanced working mechanism

1️⃣ A spacious tank made of high-quality materials. Capacity: 75 kg, allowing sufficient storage of materials to ensure continuous production without interruption. Material: Made entirely of 2 mm thick food-grade 304 stainless steel, providing high rust resistance and ensuring product hygiene.

2️⃣ Automatic extruder feeding to ensure consistent flow. The conveyor automatically feeds materials into the extruder, reducing the need for manual intervention and ensuring efficient work continuity. A precise spiral design ensures smooth material transfer without clumping or interrupting flow.

3️⃣ A high-security worker safety system equipped with a metal mesh as mechanical protection to prevent the operator's hand from entering the conveyor during operation, providing a safe working environment.

4️⃣ Efficient removal of metal impurities. Equipped with an advanced magnetic mechanism that removes any metal impurities that may be present within the materials, preserving the quality of the final product and protecting the machines from damage.

5️⃣ Easy cleaning and maintenance. Equipped with a dedicated bottom opening for cleaning, facilitating periodic maintenance and removing any material residue inside the tank. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 1.25 kW | 380/220 V | 50 Hz.

✅ Dimensions:

Length: 300 cm

Width: 90 cm

Height: 250 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey - High-quality manufacturing according to European standards. Robust design and high operating efficiency.

✔ 2 mm thick internal structure for corrosion resistance and long-lasting durability.

✔️ Precise spiral design for uniform material transfer without clumping.

✔️ Easy discharge system via the bottom opening, facilitating maintenance and cleaning.

✔️ High mechanical protection to ensure worker safety during operation.

✔️ Effective removal of metal impurities using the built-in magnet.

✔️ Automatic extruder feeding to ensure consistent flow and improve production efficiency.

✔️ Durable construction made of food-grade 304 stainless steel to maintain hygiene and quality.

✔️ Integrated safety system with metal mesh to prevent accidents during operation.

✔️ Efficient removal of metal impurities using a built-in magnetic system.

✔️ Easy maintenance and cleaning thanks to the dedicated bottom opening.

✔️ Energy-saving design with low power consumption.

💡 The ideal solution for precise and safe material transfer, while achieving the highest standards of quality and operational efficiency!

Extruder

Professional performance for producing the highest-quality puffed grains. The extruder is an essential piece of equipment in the food industry. It produces puffed grains in various shapes using advanced manufacturing techniques, ensuring consistent production with high efficiency and precise control over the shape and size of the final product. Advanced operating mechanism

1️⃣ High production capacity and continuous operating efficiency. Production capacity: ranges from 200 kg per hour, depending on the desired grain shape. Designed for 24-hour continuous operation thanks to a heavy-duty gearbox made of the finest metals, complying with American Extrusion standards.

2️⃣ Robust structure to ensure durability and sustainability. The main carrier is made of steel heat-coated using the latest furnaces to protect it from corrosion and shock. It is fully insulated with a layer of 304 food-grade stainless steel to ensure easy cleaning and adherence to health standards. Approximate weight: 1300 kg, providing stability and consistency during operation.

3️⃣ Advanced transmission system for higher reliability. The bearings and bearings are Swedish and Japanese-made SKF, ensuring smooth performance and a long operational life. The screws are made of the finest metals and heat-treated using the latest vacuum furnace technology, ensuring they can withstand high temperatures and pressures during operation. Equipped with a main screw that automatically feeds material to the compressor screw via an inverter, allowing precise control of the feeding process.

4️⃣ Integrated electronic control for flexible operation. All extruder motors are electronically controlled via three inverters, ensuring smooth control at various speeds. An electronically variable speed inverter allows for easy adjustment of the grain length according to production needs. Equipped with a start-up heater with precise electronic temperature control.

5️⃣ Dual cooling to maintain stable performance. A water-cooled (closed circuit) system based on the American Extrusion model ensures high cooling efficiency and reduces water consumption. An additional air-cooled system maintains stable temperatures during continuous operation.

6️⃣ Smart control panel for efficient process monitoring. An independent main control panel made of food-grade 304 stainless steel, equipped with a special ventilation system for hot areas. It is equipped with 3 ventilation filters and 3 cooling fans to ensure stable performance in harsh industrial environments. The control panel is tightly insulated to prevent dust ingress, ensuring clean and stable operation. It is equipped with a classic panel for full control of the operating mechanism, with an advanced software system capable of automatically reading faults and alerting when any malfunction occurs. Automatic storage of operating data is possible, with a detailed electrical diagram included for easy maintenance and inspection. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of quality and hygiene.

✅ Electrical Power: 45 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 150 cm

Width: 110 cm

Height: 240 cm

✅ Machine Number: 003

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High industrial quality according to European standards. Durable design and high-efficiency performance.

✔️ Main carrier made of heat-coated steel to withstand harsh operating conditions.

✔️ Automatic feeding system via the main screw, electronically controlled to ensure a consistent flow of material.

✔️ 50 HP (37 kW) compressor screw motor, Italian-made, with copper windings for durability and stable performance.

✔️ Main motor body made of cast iron for increased durability and pressure tolerance.

✔️ Fully electronic speed and length control via advanced inverters.

✔️ Dual cooling system (water + air) to maintain constant temperatures during continuous operation.

✔️ Smart, airtight control panel with a special cooling and ventilation system for hot areas.

✔️ Production capacity up to 200 kg/hour with easy grain shape control.

✔️ Powerful, highly efficient motors from trusted international brands.

✔️ Durable, food-grade 304 stainless steel design ensures hygiene and easy cleaning.

✔️ Dual cooling system maintains stable performance and prevents overheating.

✔️ Fully electronically controlled via advanced inverters to ensure precise and smooth operation.

✔️ Advanced control panel capable of reading faults and storing operational data.

✔️ Safe and environmentally friendly design with a closed cooling system to save water.

💡 The ideal solution for producing high-quality puffed grains, with the highest levels of efficiency and consistent performance!

Conveyor belt for the product

Professional Product Transfer Between Manufacturing Stages. Product conveyor belts are essential equipment in production lines, ensuring smooth and safe transfer of materials from the extruder to the oven. Their robust design and advanced features ensure the highest standards of hygiene and efficiency. Advanced Operation Mechanism

1️⃣ Sturdy structure to ensure durability and longevity. Made entirely of 304 food-grade stainless steel, they are highly resistant to rust and easy to clean. They are equipped with sturdy wheels for easy movement and periodic cleaning within the production line.

2️⃣ High-quality food-grade conveyor belt. The conveyor belt is made of PVC or food-grade plastic to ensure hygienic and safe product transfer. The surface has a non-stick texture to prevent material from sticking during transfer, thus preserving product quality.

3️⃣ Integrated cleaning system with dedicated cleaning holes for easy maintenance and preventing residue buildup. They include automatic cleaning brushes that operate continuously to remove any impurities or residual materials during operation.

4️⃣ Highly efficient and economical operation. They consume low energy (1.25 kW), ensuring economical operation without energy waste. Technical Specifications

✅ Material: Made entirely of 304 food-grade stainless steel to ensure hygiene and durability.

✅ Electrical Power: 1.25 kW | 380/220 V | 50 Hz.

✅ Dimensions:

Length: 300 cm

Width: 80 cm

Height: 200 cm

✅ Machine Number: 004

✅ Model: THV-2025PV-Z

✅ Country of Manufacture: Turkey - High industrial quality according to European standards. Product Conveyor Features

✔️ Durable design entirely made of 304 food-grade stainless steel to ensure the highest hygiene standards.

✔️ Smooth and safe transfer of materials from the extruder to the oven without any damage to the product.

✔️ Conveyor belt made of PVC or food-grade plastic to ensure hygienic transportation.

✔️ Built-in automatic cleaning system with cleaning brushes and maintenance holes.

✔️ Wheels for easy movement and cleaning, providing operational flexibility.

✔️ Low energy consumption with high operating efficiency.

💡 The ideal solution for safely and efficiently transporting product within food production lines!

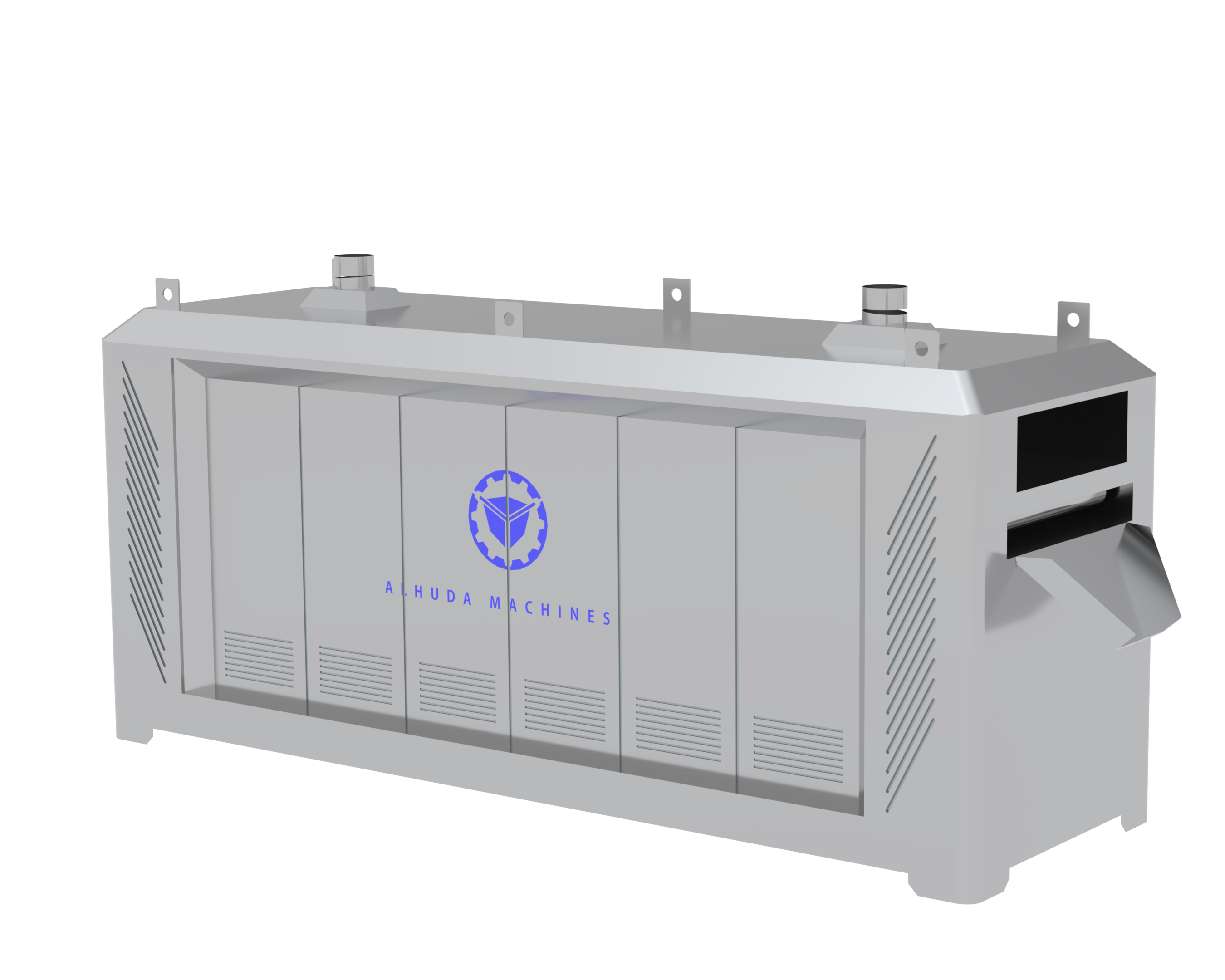

Hot air grill oven

Professional Roasting and Drying Using Hot Air Technology The hot air roasting oven is one of the latest technologies used in roasting and drying chips. It relies on homogeneous heat distribution to ensure the production of a final product of optimal quality, with precise humidity and temperature control to adjust the texture and taste as desired. Advanced Operation Mechanism

1️⃣ High productivity with precise temperature control Production capacity up to 300 kg per hour, making it ideal for large production lines. The temperature can be adjusted up to 300°C depending on the product type and manufacturing requirements. The humidity of the final product can be controlled from 0% to 5% as required to ensure the ideal texture.

2️⃣ Efficient and Energy-Saving Heating System Operates on diesel or natural gas (LPG) as desired by the customer, ensuring economical and efficient operation. Equipped with a built-in heating chamber that can be detached and installed for easy maintenance. Made of 304 chrome and stainless steel, it can withstand temperatures up to 800°C. The primary burner is Baltur or Riello (Italian - Model 2025), ensuring high operating efficiency.

3️⃣ Robust construction and perfect thermal insulation Made entirely of 304 food-grade stainless steel to ensure high rust resistance and ease of cleaning. The oven is fully insulated with a 15 cm thick fiberglass layer on all sides to maintain internal heat and reduce energy consumption.

4️⃣ Advanced product conveyor system with automatic cleaning The conveyor belt is made of 100 cm wide 304 food-grade Professional Roasting and Drying Using Hot Air Technology. The hot air roasting oven is one of the latest technologies used in roasting and drying chips. It relies on homogeneous heat distribution, ensuring the production of a final product of optimal quality, with precise humidity and temperature control to adjust the desired texture and taste. Advanced Operation Mechanism

1️⃣ High productivity with precise temperature control. Production capacity reaches 300 kg per hour, making it ideal for large production lines. Temperature can be adjusted up to 300°C depending on the product type and manufacturing requirements. The humidity of the final product can be controlled from 0% to 5% upon request to ensure the ideal texture.

2️⃣ An efficient and energy-saving heating system that runs on diesel or natural gas (LPG) as desired by the customer, ensuring economical and efficient operation. It is equipped with a detachable and integrated heating chamber for easy maintenance, made of 304 chrome and stainless steel to withstand temperatures up to 800°C. The primary burner, Baltur or Riello (Italian - Model 2025), ensures high operating efficiency.

3️⃣ A sturdy structure with optimal thermal insulation, made entirely of 304 food-grade stainless steel to ensure high rust resistance and easy cleaning. The oven is fully insulated with a 15 cm thick layer of fiberglass on all sides to maintain internal heat and reduce energy consumption.

4️⃣ Advanced product conveyor system with automatic cleaning. The conveyor grate is made of 100 cm wide 304 food-grade stainless steel, ensuring even roasting. It is equipped with an automatic conveyor grate cleaning mechanism, maintaining product cleanliness and operating efficiency. The oven is equipped with an LS inverter for precise control of grate speed.

5️⃣ Professional air distribution for even roasting. It is equipped with powerful hot air pumping and circulating fans to ensure optimal heat distribution from the top and bottom with side recirculation. 3 HP hot air pumping fan motor (Italian or Turkish - excellent quality). 3 HP air extraction and circulating fan motor (Italian or Turkish - excellent quality).

6️⃣ Advanced operating and control system. A separate control panel made of 304 food-grade stainless steel, removable and reusable for easy maintenance and transportation. A modern touch screen with a smart fault reading system via text messages to quickly identify and resolve problems. All electrical parts are Schneider (France) and LS (Korea) to ensure high operational reliability. The main gearbox is Italian, and the motors are Italian or Turkish of excellent quality. The rotation of the hot air pumping and circulation fans is electronically controlled via inverters. Technical Specifications

✅ Material: Made entirely of 304 food-grade stainless steel to ensure the highest standards of hygiene and quality.

✅ Electrical Power: 10.5 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 650 cm

Width: 140 cm

Height: 200 cm

✅ Machine Number: 005

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey - High industrial quality according to European standards. Features of the Hot Air Roasting Oven

✔️ High production capacity of up to 300 kg/hour with precise humidity and temperature control.

✔️ Durable design and optimal thermal insulation to maintain internal temperature and reduce energy consumption.

✔️ Integrated heating chamber that can be detached and installed for easy maintenance.

✔️ Advanced air distribution system to ensure even roasting on all sides.

✔️ Conveyor grill made of 304 food-grade stainless steel with an automatic cleaning system.

✔️ Smart touch screen control panel with automatic fault reading system.

✔️ Powerful European-quality motors and fans to ensure continuous production.

💡 The perfect solution for high-quality roasted chips, delicious taste, and perfect texture!

Two flavor mixer tanks

Precise Flavor Preparation with Indirect Heating Technology. Flavor cooking tanks are designed to ensure the highest quality food flavors are prepared. They rely on an indirect (double jacket) heating system to provide even heating without affecting the flavor composition, enhancing optimal flavor distribution throughout the final product. Advanced Operation Mechanism

1️⃣ Professionally designed indirect heating system. The tank is made with double jacket technology, which allows the surrounding water to be heated instead of directly heating the flavor. This ensures that the flavor is maintained at its optimal quality without burning or changing its composition. It has a heating capacity of approximately 200 liters, making it ideal for large production lines. It is equipped with an indicator to monitor the hot water level inside the tank to ensure proper and continuous operation.

2️⃣ Durable and industrial-grade construction. It is made entirely of food-grade 304 stainless steel, ensuring high rust resistance and ease of cleaning and sterilization. The main chassis is made of heat-coated iron and covered with stainless steel for high durability and added protection. The tanks and pump are mounted on a single chassis for easy installation and maintenance. It is equipped with sturdy wheels for easy movement and cleaning, making it easy to move within production lines.

A precise temperature control system with a digital thermometer continuously reads the hot water temperature inside the tank, ensuring precise control over the heating process. A homogeneous heat distribution system prevents the formation of heat spots within the flavor, ensuring the consistency of the final product. Technical Specifications

✅ Material: Made entirely of 304 food-grade stainless steel to ensure the highest standards of hygiene and quality.

✅ Electrical Power: 3.75 kW | 380/220 V | 50 Hz.

✅ Dimensions:

Length: 230 cm

Width: 130 cm

Height: 170 cm

✅ Machine Number: 006

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey - High industrial quality according to European standards. Flavor Cooking Tank Features

✔️ Double-jacket design for indirect heating, preserving flavor quality.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with a hot water level indicator and a thermometer for precise temperature monitoring.

✔️ Sturdy chassis made of heat-coated steel for durability and longevity.

✔️ Equipped with wheels for easy movement and cleaning, making it easy to use on various production lines.

✔️ Large capacity of up to 250 liters, making it ideal for large-scale industrial production.

💡 The perfect solution for preparing flavors with the highest levels of precision and quality!

Flavor pump

Precise Flavor Preparation with Indirect Heating Technology. Flavor cooking tanks are designed to ensure the highest quality food flavors are prepared. They rely on an indirect (double jacket) heating system to provide even heating without affecting the flavor composition, enhancing optimal flavor distribution throughout the final product. Advanced Operation Mechanism

1️⃣ Professionally designed indirect heating system. The tank is made with double jacket technology, which allows the surrounding water to be heated instead of directly heating the flavor. This ensures that the flavor is maintained at its optimal quality without burning or changing its composition. It has a heating capacity of approximately 200 liters, making it ideal for large production lines. It is equipped with an indicator to monitor the hot water level inside the tank to ensure proper and continuous operation.

2️⃣ Durable and industrial-grade construction. It is made entirely of food-grade 304 stainless steel, ensuring high rust resistance and ease of cleaning and sterilization. The main chassis is made of heat-coated iron and covered with stainless steel for high durability and added protection. The tanks and pump are mounted on a single chassis for easy installation and maintenance. It is equipped with sturdy wheels for easy movement and cleaning, making it easy to move within production lines.

A precise temperature control system with a digital thermometer continuously reads the hot water temperature inside the tank, ensuring precise control over the heating process. A homogeneous heat distribution system prevents the formation of heat spots within the flavor, ensuring the consistency of the final product. Technical Specifications

✅ Material: Made entirely of 304 food-grade stainless steel to ensure the highest standards of hygiene and quality.

✅ Electrical Power: 3.75 kW | 380/220 V | 50 Hz.

✅ Dimensions:

Length: 230 cm

Width: 130 cm

Height: 170 cm

✅ Machine Number: 006

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey - High industrial quality according to European standards. Flavor Cooking Tank Features

✔️ Double-jacket design for indirect heating, preserving flavor quality.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with a hot water level indicator and a thermometer for precise temperature monitoring.

✔️ Sturdy chassis made of heat-coated steel for durability and longevity.

✔️ Equipped with wheels for easy movement and cleaning, making it easy to use on various production lines.

✔️ Large capacity of up to 250 liters, making it ideal for large-scale industrial production.

💡 The perfect solution for preparing flavors with the highest levels of precision and quality!

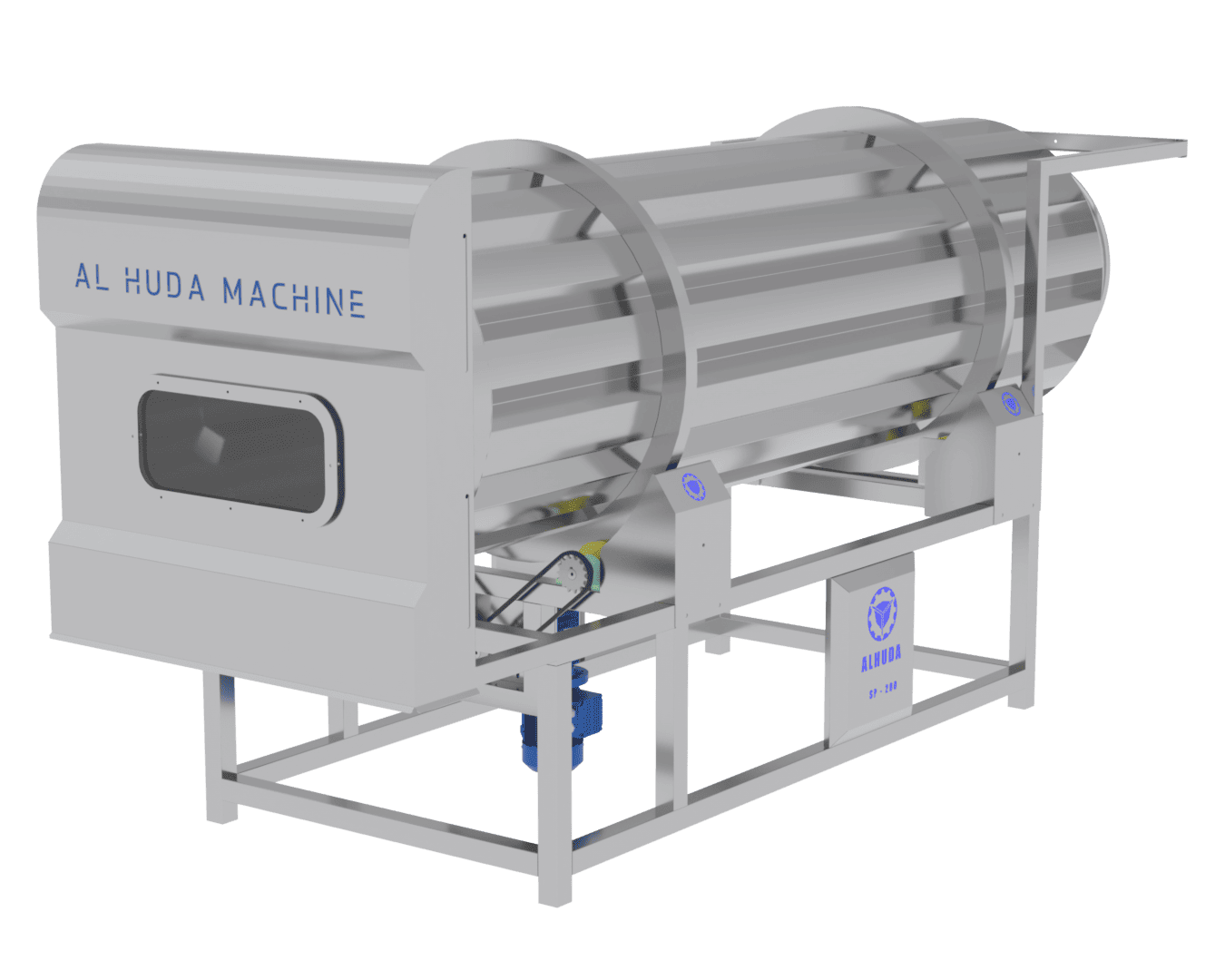

Flavor coating cylinder

Homogeneous flavoring for optimal taste and quality. The seasoning process is one of the most important stages in chip production, ensuring even flavor distribution across all chips using an advanced flavor spray system and a slow, balanced rotation mechanism that prevents clumping or settling. Advanced Mechanism

1️⃣ Precise Electronic Control System: The rotation speed of the seasoning machine is electronically controlled via an inverter, allowing the time the chips pass through the drum to be adjusted according to the product type. The seasoning machine is calibratable to adjust the flavor level as needed, ensuring consistent results for every batch.

2️⃣ Advanced Flavor Sprayer for optimal coverage. Equipped with a high-precision flavor sprayer (an advanced calibratable American model), it ensures even and precise flavor distribution without waste. The scales inside the drum are designed to prevent flavor clumping, helping achieve even flavoring for every chip.

3️⃣ Impurity ejection mechanism to improve product quality. Equipped with an automatic ejection mechanism for impurities and unwanted small particles, ensuring the final product has the perfect size and texture. The chips rotate slowly while dispersing the flavor, helping to fully cover the chips without breaking them.

4️⃣ Durable and easy-to-clean design. Made entirely of 304 food-grade stainless steel to ensure the highest standards of hygiene and health. Equipped with a chrome cover at the material exit end to protect the product and prevent waste. Equipped with sturdy wheels for easy stirring and cleaning, making it ideal for industrial environments. Technical Specifications

✅ Material: Made entirely of 304 food-grade stainless steel to ensure the highest levels of hygiene and quality.

✅ Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 300 cm

Width: 120 cm

Height: 150 cm

✅ Machine Number: 007

✅ Model: THV-2025PV-Z

✅ Country of Manufacture: Turkey - High industrial quality according to European standards.

Mariner Features

✔️ Electronic inverter control system to adjust the drum rotation speed.

✔️ Advanced American flavor sprayer for optimal flavor distribution.

✔️ Internal design with scales to prevent flavor clumping and ensure consistent flavoring.

✔️ Automatic ejection mechanism for unwanted impurities and particles.

✔️ Made entirely of 304 food-grade stainless steel for rust resistance and easy cleaning.

✔️ Equipped with sturdy wheels for easy stirring and cleaning.

💡 The perfect solution for consistent flavoring and ensuring high-quality chips!

Server conveyor belt

Precise and Balanced Conveyance to Maintain Product Quality The conveyor belt is one of the most important stages of potato chips production. It ensures efficient transfer of the product from the flavoring stage to three packaging machines, while preserving the integrity of the chips through a fully automated and precise distribution system. Advanced Operation Mechanism 1️⃣ Precise Electronic Control System The product transfer speed is controlled by an electronic control circuit equipped with modern sensors, allowing for balanced product feeding according to the capacity of the packaging machines. ✅ Equipped with a reservoir and vibrator to ensure a homogeneous flow of chips without accumulation or jamming. ✅ Fully automated to reduce manual intervention and increase production efficiency. 2️⃣ Conveyor belt with an advanced design equipped with a Z-shaped PVC belt to facilitate product transfer at an appropriate angle, helping achieve optimal flow without affecting the shape of the chips. ✅ Made of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality. ✅ Its design reduces vibration and shock, keeping the product unbroken. 3️⃣ Smart Sensors for Improved Performance It features advanced electronic sensors that automatically adjust the speed and flow of the product, preventing any buildup or congestion in the production line. ✅ Ensures even product distribution between the packaging machines for stable and consistent production. 4️⃣ Durable and Easy-to-Clean Design Made entirely of food-grade 304 stainless steel to ensure rust resistance and easy cleaning, with a robust structure to withstand continuous operation in industrial environments. ✅ Equipped with sturdy wheels for easy movement and maintenance. Technical Specifications ✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest levels of hygiene and quality. ✅ Electrical Power: 5.25 kW | 380/220 V | 50 Hz. ✅ Dimensions: Length: 14 cm Width: 90 cm Height: 380 cm ✅ Machine Number: 009 ✅ Model: THV-2025PV-Z ✅ Country of Manufacture: Turkey Features of the Feeding Conveyor Line ✔️ Precise electronic control system with sensors to automatically adjust the product conveying speed. ✔️ Z-shaped PVC conveyor ensures optimal flow without compromising the quality of the slices. ✔️ Shock and vibration-resistant design to protect the product from breakage. ✔️ Tank and vibrator to ensure consistent flow and prevent product accumulation during conveying. ✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning. ✔️ Equipped with sturdy wheels for easy movement and cleaning, making it ideal for industrial environments. 💡 The ideal solution for efficient product transfer and ensuring the highest levels of production quality!

CONTINUOUS SYSTEM GRAVIMETRIC PACKAGING MACHINES 3PCS

Accurate and Speedy Food Packaging with Advanced Systems The weight packaging machine is designed according to the latest international technologies to ensure high speed, 24-hour operation, and superior accuracy in weighing and packaging. It features advanced drive systems, precise optical sensors, and an integrated electronic control system that ensures high efficiency and consistent production. Advanced Operation Mechanism: 1️⃣ Precise and Flexible Packaging System Automatic packaging of potato chips, chips, seeds, and nuts. Relies on an intelligent weighing system to ensure accurate packaging and reduce waste. 2️⃣ Advanced Electronic Control for Smooth Operations Advanced PLC system from Delta for fast response and precise control. 7-inch electronic touch screen from Delta for ease of operation. Precise OMRON thermal control system allows temperature adjustment from the screen to ensure weld quality. 3️⃣ High Performance with Powerful Motors Equipped with motors and gearboxes to control the conveyor belt and jaws, ensuring stable operation. A stepper motor for automatic roll holder movement, controlled via a screen. A stepper motor for roll drawback compensation, with an alarm system when the roll is finished. 4️⃣ Safe and durable design Safety sensors protect the operator from any operational errors. A comprehensive daily production counter for performance monitoring and effective production tracking. The entire body is made of 304 food-grade stainless steel to ensure hygiene and product safety. All parts in contact with the product are made of 304 stainless steel in accordance with food-grade quality standards. 5️⃣ Flexible roll usage Roll width can be customized to suit customer requirements, allowing for the packaging of a variety of products. Maximum roll length: 320 mm. An Italian-made roll forming device, easy to replace for increased operational efficiency. Supports the use of built-in cellophane rolls to ensure tight, high-quality packaging. 6️⃣ Additional equipment for increased efficiency A Z-type PVC conveyor belt with a 304 stainless steel body and an automatic feeding system. Conveyor belt for finished packages to ensure easy transportation and storage. Date printer to print product information directly onto the package. Smart weighing system from HIGH DREAM to ensure high weight accuracy. Weighing platform made of 304 stainless steel to ensure stability and reliability. Technical Specifications: ✅ Material: Made entirely of food-grade 304 stainless steel to maintain hygiene and quality. ✅ Electrical Power: 5.75 kW | 380/220 V | 50 Hz. ✅ Dimensions: Length: 200 cm Width: 130 cm Height: 420 cm 🔢 Machine Number: 024 ✅ Model: THV-2024PV-B ✅ Country of Origin: Turkey Durable design to ensure high performance: ✔️ High weight accuracy via the intelligent summation system. ✔️ Comprehensive electronic control for maximum operational efficiency. ✔️ Integrated safety with safety sensors to protect the operator. ✔️ Flexibility in using packaging rolls according to customer needs. ✔️ High-quality European components to ensure machine durability. Features of the weight packaging machine: ✔️ High speed and high accuracy in packaging. ✔️ Advanced PLC electronic control system enables smooth and responsive operation. ✔️ Durable 304 stainless steel construction materials to ensure hygiene and product safety. ✔️ Practical and easy-to-maintain design to extend the machine's lifespan. ✔️ Integrated safety systems to ensure operator safety. 💡 The ideal solution for filling and packaging food products with utmost efficiency and precision!

control Board

Schneider breakers

Schneider contactors

Delta control panel

Delta inverters

Gamak motors

Yilmaz gearboxes

Or as per customer request

basic information

🌽✨ Corn Chips Production Line – The smart solution for producing unparalleled quality crisps in a competitive world of food industries. Al-Huda International Company stands out with its corn chips production line as a smart, technologically advanced investment option that suits your ambitions and delivers guaranteed profits in the chips and crisps markets.

🏭 Efficient Manufacturing and Tasty Creativity. This line is specifically designed to convert corn flour into crunchy, delicious, and healthy chips, using modern technologies including mixing, extrusion, shaping, drying, seasoning, and finally packaging.

⚙️ Main Line Components – European technology and impeccable precision:

1️⃣ Raw Material Mixing Unit

🔹 Precisely mixes corn flour with water and additional ingredients to produce a homogeneous dough.

2️⃣ Extruder

🔹 Operates with heat and high pressure to form the dough into attractive and varied shapes according to the customer's desires.

3️⃣ Shaping and Cutting Device

🔹 Precisely cuts the product to the desired size and shape before drying.

4️⃣ Hot Air Dryer

🔹 Removes excess moisture and ensures a balanced crispiness in the final product.

5️⃣ Hot Air Oven

🔹 For healthy, oil-free roasting – ideal results with a lower-fat, longer-lasting product.

6️⃣ Seasoning and Flavoring Unit

🔹 Adds the desired flavors with even distribution and an irresistible taste.

7️⃣ Packaging Machine

🔹 Automatic, airtight packaging maintains product quality and freshness for a longer period.

🌟 Features of the Al-Huda Corn Chips Production Line:

✅ High productivity – Fully automatic design ensures continuity and efficiency.

✅ Great flexibility – Produces more than 30 different shapes of corn chips and snacks.

✅ Control the quality of taste and texture – every piece comes out with the same quality and balance.

✅ Energy and oil efficiency – Economical and environmentally friendly performance.

✅ Simple operation and a hygienic structure – Made entirely of 304 food-grade stainless steel according to international standards.

📐 Dimensions and Required Space:

🔹 Complete line length: approximately 27 meters

🔹 Required width: approximately 3 meters

🔹 Required space: approximately 300 square meters

🛡️ Trust Guarantee – A complete trial before you buy. At Al-Huda, we don't just sell a machine... we offer you a partner in success.

🔧 The entire line is tested at our factory in Gaziantep, Turkey, in the presence of the customer, to ensure full compliance with the agreed-upon specifications.

📝 In the event of dissatisfaction, the customer has the right to a refund without obligation.

🏆 Why Al-Huda?

✅ Over 20 years of engineering experience and professionalism in the food machinery industry.

✅ Production lines certified to international quality standards, ISO and CE.

✅ Continuous technical support – before and after the sale.

✅ Line customization available based on product type and target market.

✅ Fast shipping, full training, and commissioning in the customer's country.

📩 We are waiting for your message now! We will provide you with a detailed catalog, high-resolution images and videos, and a personalized quote.

🌟 Al-Huda Company – Your partner in success, a trusted builder of quality and craftsmanship. We don't just offer a production line… We offer you a real project that will change your future.

🛠️ Al-Huda International – Where success begins, and crisps are made with excellence.

Gallery