Cheetos chips production line with oven system, production capacity 200 kg

Cheetos-style snack chips production line with oven baking system: Operating principle:

Cheetos-style snack chips are made from corn, which is extruded into shape and then baked in a heated oven, instead of being fried in oil. Ease of operation:

The production line is easy to operate via a simple control panel, allowing for seamless monitoring and adjustment of settings.

Manufacturing quality: The line is made of durable, high-quality materials to ensure long-lasting performance and consistent product quality. Final product:

The resulting Cheetos-style snack chips have a distinctive flavor and a light, crispy texture, without the use of oil.

The line consists of the following parts

1. Corn mixer

2. Screw conveyor

3. Extruder

4. Product conveyor belt

5. Sifter

6. Hot air oven

7. Conveyor belt system

8. Flavoring mixing tanks

9. Flavoring pump

10. Flavor coating drum

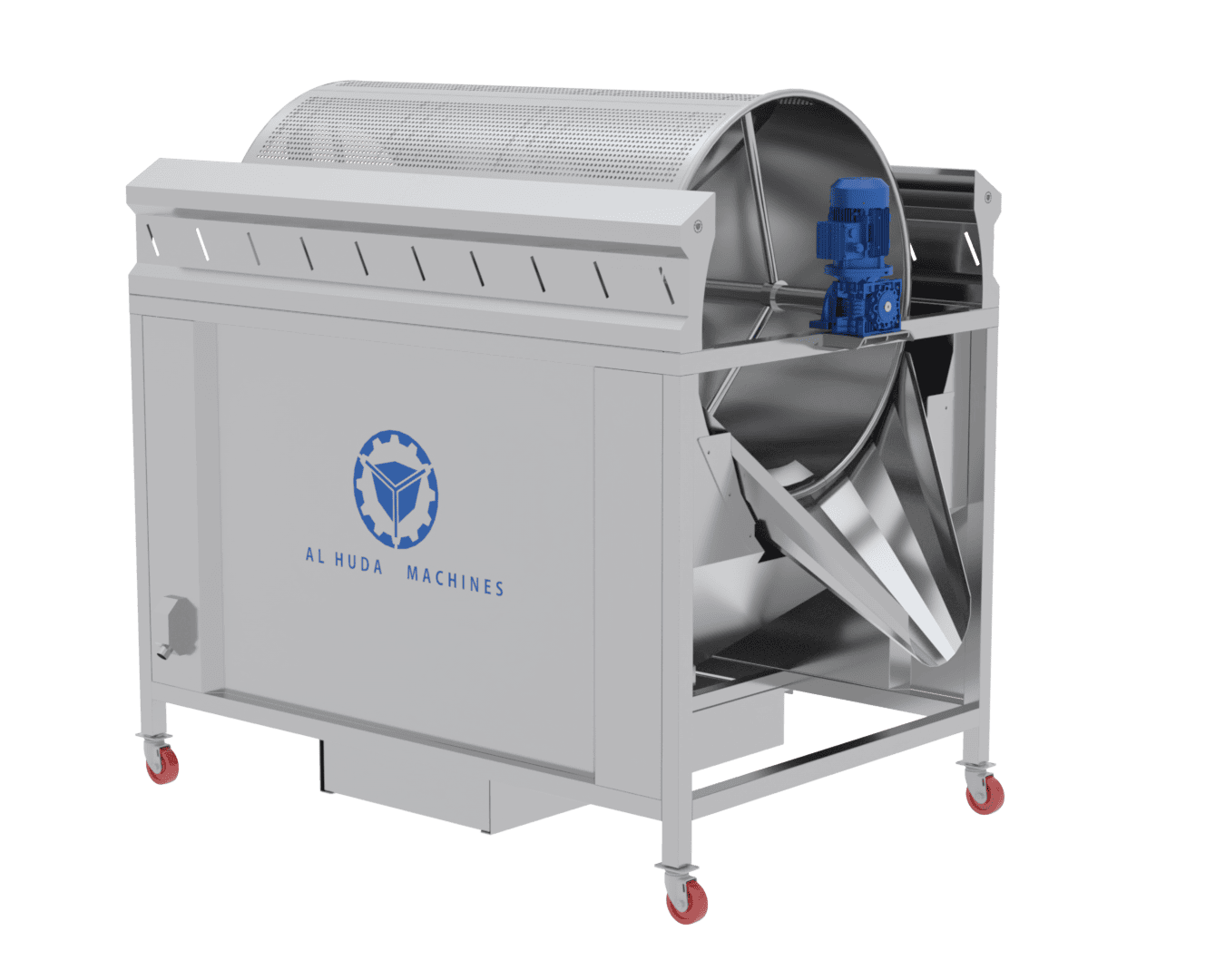

corn mixer

Homogeneous and precise mixing of corn at the highest quality standards. The corn mixer is essential equipment in corn processing before manufacturing, as it achieves perfect homogeneity in mixing the corn while adding a precise amount of moisture, ensuring even distribution and professional preparation of the final product. Advanced operating mechanism:

1️⃣ Large capacity and high-quality materials. Capacity: 400 kg, allowing for efficient processing of large quantities of corn. Material: Made entirely of 2 mm thick food-grade 304 stainless steel, ensuring rust resistance and maintaining product hygiene.

2️⃣ Powerful motor for optimal mixing. Main motor: 5 HP, Turkish-made, ensuring stable performance and high mixing efficiency. A homogeneous mixing mechanism guarantees perfect distribution of ingredients within the mixer.

3️⃣ Precise control of corn moisture. Equipped with a built-in water tank, allowing control of the corn's moisture content to achieve the desired consistency. A water level indicator helps in accurately adjusting the amount during the mixing process.

4️⃣ High safety system for worker protection. Equipped with a mechanical safety guard (metal mesh) that prevents the operator's hand from entering the mixer during operation, ensuring a safe working environment.

5️⃣ Smooth discharge and control system. Features a calibrated discharge opening for easy product removal without clumping or material loss. Includes a viewing and cleaning port, allowing monitoring of the mixing process and ensuring the mixer remains clean after each use.

6️⃣ Effective removal of metal impurities. The mixer bowl contains a powerful magnet that removes any metal impurities from the corn, ensuring the purity of the final product and preventing unwanted materials from entering subsequent production stages. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 180 cm

Width: 120 cm

Height: 230 cm

✅ Machine Number: 001

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Durable construction and high performance.

✔️ 2 mm thick inner lining for corrosion resistance and long-lasting durability.

✔️ Smooth discharge system for easy control of the corn output after mixing.

✔️ High-level mechanical safety features to ensure operator safety during operation.

✔️ Magnet inside the mixing bowl to remove any metal impurities that could affect product quality.

✔️ Precise control of corn moisture through a built-in water tank and level indicator.

✔️ Robust and durable design made entirely of food-grade 304 stainless steel for maximum hygiene.

✔️ High-level safety system with a metal mesh guard to prevent accidental contact with moving parts.

✔️ Effective removal of metal impurities using the built-in magnet in the mixing bowl.

✔️ Easy emptying and cleaning through designated openings.

✔️ High-performance motor for optimal mixing efficiency and superior product quality.

💡 The ideal solution for ensuring consistent mixing and professional corn preparation with the best quality and operational efficiency!

screw conveyor

Precise and efficient automated material conveying for maximum safety and quality. The screw conveyor is a vital piece of equipment in production lines, automatically feeding materials to the extruder smoothly and efficiently, ensuring consistent flow, improved production efficiency, and the highest levels of safety and quality. Advanced operating mechanism:

1️⃣ Spacious hopper made of high-quality materials: Capacity: 75 kg, allowing sufficient storage to maintain continuous production. Material: Made entirely of 2mm thick food-grade 304 stainless steel, providing high corrosion resistance and ensuring product hygiene.

2️⃣ Automatic feeding to the extruder for consistent flow: The conveyor automatically feeds materials to the extruder, minimizing manual intervention and ensuring continuous and efficient operation. Its precise screw design guarantees smooth material transport without clumping or flow interruptions.

3️⃣ Robust safety system for worker protection: Equipped with a safety mesh to prevent accidental contact with the moving parts during operation, ensuring a safe working environment.

4️⃣ Efficient metal impurity removal: Features a sophisticated magnetic system that effectively removes any metal impurities from the material, maintaining product quality and protecting the machinery from damage.

5️⃣ Easy cleaning and maintenance: A dedicated bottom opening facilitates routine maintenance and removal of any residual material from the hopper. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Power: 1.25 kW | 380/220 V | 50 Hz. ✅ Dimensions:

Length: 300 cm

Width: 90 cm

Height: 250 cm

✅ Machine Number: 002

✅ Model: THV-2025PV-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Robust design and high operational efficiency.

✔️ 2 mm thick inner frame for corrosion resistance and long-lasting durability.

✔️ Precise helical design for even material transport without clumping.

✔️ Easy discharge system via the bottom opening, facilitating maintenance and cleaning.

✔️ High-level mechanical safety features to ensure operator safety during operation.

✔️ Effective removal of metal impurities using the integrated magnetic system.

✔️ Automatic feeder for consistent material flow and improved production efficiency.

✔️ Durable frame made of food-grade 304 stainless steel for hygiene and quality.

✔️ Integrated safety system with a protective mesh to prevent accidents during operation.

✔️ Efficient removal of metal impurities with the built-in magnetic system.

✔️ Easy maintenance and cleaning thanks to the dedicated bottom access panel.

✔️ Energy-efficient design with low power consumption.

💡 The ideal solution for precise and safe material handling, achieving the highest quality and operational efficiency standards!

Extruder

Advanced extrusion technology – high production capacity, continuous operation, and maximum manufacturing efficiency! This extruder is designed for continuous operation, up to 24 hours a day, using the finest materials to ensure superior performance and high reliability. It is the ideal choice for producing puffed corn and various types of snack pellets in different shapes and with consistent quality.

⚙️ Advanced Operating Mechanism:

1️⃣ High Production Capacity

✔️ Production capacity of up to 175 kg per hour (depending on the desired pellet shape).

✔️ Equipped with a main feed screw that ensures precise and consistent material flow.

2️⃣ Durable and High-Quality Engineering Design

✔️ The main frame is made of thermally coated steel using the latest oven technology for resistance to various environmental factors.

✔️ The legs are made of standard-grade steel to ensure the stability and durability of the extruder during operation.

3️⃣ Integrated Insulation and Robust Structure

✔️ Fully insulated with a 304 food-grade stainless steel outer layer for hygiene and easy maintenance.

✔️ The control panel is separate from the main body and features 3 ventilation filters and 3 cooling fans to protect the electronic components.

4️⃣ Professional Gearbox

✔️ Made from the finest materials, capable of withstanding long hours of continuous operation.

✔️ The gearbox is specifically designed for uninterrupted, continuous operation, with high efficiency and stable performance.

5️⃣ Heat-Treated Screws

✔️ All screws are made of the best materials and treated using the latest vacuum heat treatment oven technology to increase their lifespan and corrosion resistance.

6️⃣ Powerful Motors with Full Electronic Control

✔️ 30 HP (22.5 kW) screw compressor motor with genuine copper windings.

✔️ The motor frame is made of high-durability cast iron.

✔️ The speed of all motors is controlled by 3 electronic inverters to ensure smooth operation and energy efficiency.

7️⃣ Smart Heating System for Easy Startup

✔️ Equipped with an electronic heating system for easy startup, featuring a thermostat for precise temperature control.

8️⃣ Smart and Advanced Control Panel

✔️ Main control panel made of food-grade 304 stainless steel with a special ventilation system, dust-proof and heat-resistant.

✔️ Features an automatic fault detection system with the ability to store operational data.

✔️ Includes a complete and detailed electrical diagram for easy maintenance and periodic inspection.

📏 Technical Specifications:

✅ Power Supply: 380/220VAC – 50Hz – 39.75 kW

▫️ Length: 200 cm

▫️ Width: 100 cm

▫️ Height: 200 cm

✅ Approximate Weight: 1300 kg

✅ Machine Number: 003

✅ Model: THV-2024SH-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Robust design and high operational efficiency.

💡 Why Choose the THV-2024SH-Z Extruder?

✔️ High production capacity with flexibility in grain shapes.

✔️ Durable design for continuous 24/7 operation.

✔️ Fully insulated and robust structure, easy to clean and maintain.

✔️ Smart control panel for instant fault detection and full control.

✔️ Powerful motors with advanced electronic control for energy efficiency and enhanced performance.

🔹 The ideal choice for producing high-quality, world-class puffed corn and snacks with professional-level performance!

Chips conveyor line

A sophisticated conveyor system for efficient product transport, featuring a smart design for hygiene and easy maintenance! This conveyor smoothly transports the product from the extruder to the screen, and its fully food-grade design ensures the preservation of food quality and safety.

➤ How it works:

1. ✅ Fully food-grade construction: The conveyor is made of food-grade stainless steel (304), resistant to rust and corrosion.

2. ✅ Food-grade conveyor belt: Equipped with a high-quality PVC or food-grade plastic conveyor belt, specifically designed for safe food transport.

3. ✅ Easy cleaning: Features convenient access panels and automatic cleaning brushes for continuous hygiene without lengthy downtime.

4. ✅ Mobility: The conveyor is equipped with durable casters for easy movement and cleaning when needed.

➤ Technical Specifications: Power: 1.25 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 80 cm

Height: 300 cm

Machine Number: 004

Model: THV-2025 SH-Z

✅ Made in Turkey – High-quality industrial product, manufactured to European standards. Robust design and high operational efficiency.

➤ Why choose this conveyor?

100% hygienic design, compliant with international food standards.

Easy maintenance and cleaning for increased efficiency and reduced downtime.

Smooth and reliable operation ensures uninterrupted production flow.

European manufacturing quality guarantees long-term performance and a long service life.

The sieve

A precise technology for product purification and efficient removal of unwanted particles, ensuring high quality! This sieve separates dust and small, unwanted pieces from potato chips using a carefully designed perforated cylinder, guaranteeing optimal performance and a superior final product.

➤ How it works: 1.

✅ Perforated cylindrical design: Allows unwanted small particles to pass through the precisely designed sieve holes.

2. ✅ Waste collection: Dust and small fragments are collected in a dedicated container located below the sieve, supported by a robust frame.

3. ✅ Automatic speed control: The sieve rotates at a controlled speed, automatically adjusted to ensure perfect sorting results.

4. ✅ Food-grade construction: All parts of the sieve are made entirely of food-grade 304 stainless steel, guaranteeing the highest standards of hygiene and food safety.

➤ Technical Specifications: Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 200 cm

Width: 90 cm

Height: 270 cm

Machine Number: 005

Model: THV-2025 SH-Z

✅ Made in Turkey – High-quality industrial product, manufactured to European standards. Robust design and high operational efficiency.

➤ Why choose this sieve? High precision in sorting potato chips, resulting in a clean, impurity-free final product.

Fully food-grade construction ensures product safety.

Easy operation and control thanks to the automatic speed control system.

High-quality Turkish product, manufactured to European standards, guaranteeing reliable performance and long service life.

Chips conveyor belt

Advanced technology for efficient product conveying, with a smart engineering design that ensures hygiene and ease of maintenance! This conveyor belt smoothly transports products from the sifter to the fryer, and features a fully food-grade design that guarantees the preservation of food quality and safety.

➤ How it works:

1. ✅ Fully food-grade construction: The conveyor belt is made of food-grade stainless steel (304), resistant to rust and corrosion.

2. ✅ Food-grade conveyor belt: Equipped with a conveyor belt made of high-quality PVC or food-grade plastic, specifically designed for safe food transport.

3. ✅ Easy cleaning: Features convenient cleaning access panels and automatic cleaning brushes to ensure continuous hygiene without lengthy downtime.

4. ✅ Mobility: The conveyor belt is equipped with durable casters for easy movement and cleaning when needed.

➤ Technical Specifications: Power: 1.25 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 80 cm

Height: 300 cm

Machine Number: 006

Model: THV-2025 SH-Z

✅ Made in Turkey – High-quality industrial product, manufactured according to European standards. Robust design and high operational efficiency.

➤ Why choose this conveyor belt? 100% hygienic design, compliant with international food standards.

Easy maintenance and cleaning for increased efficiency and reduced downtime.

Smooth and reliable operation ensures uninterrupted production flow.

European manufacturing quality guarantees long-term performance and a long service life.

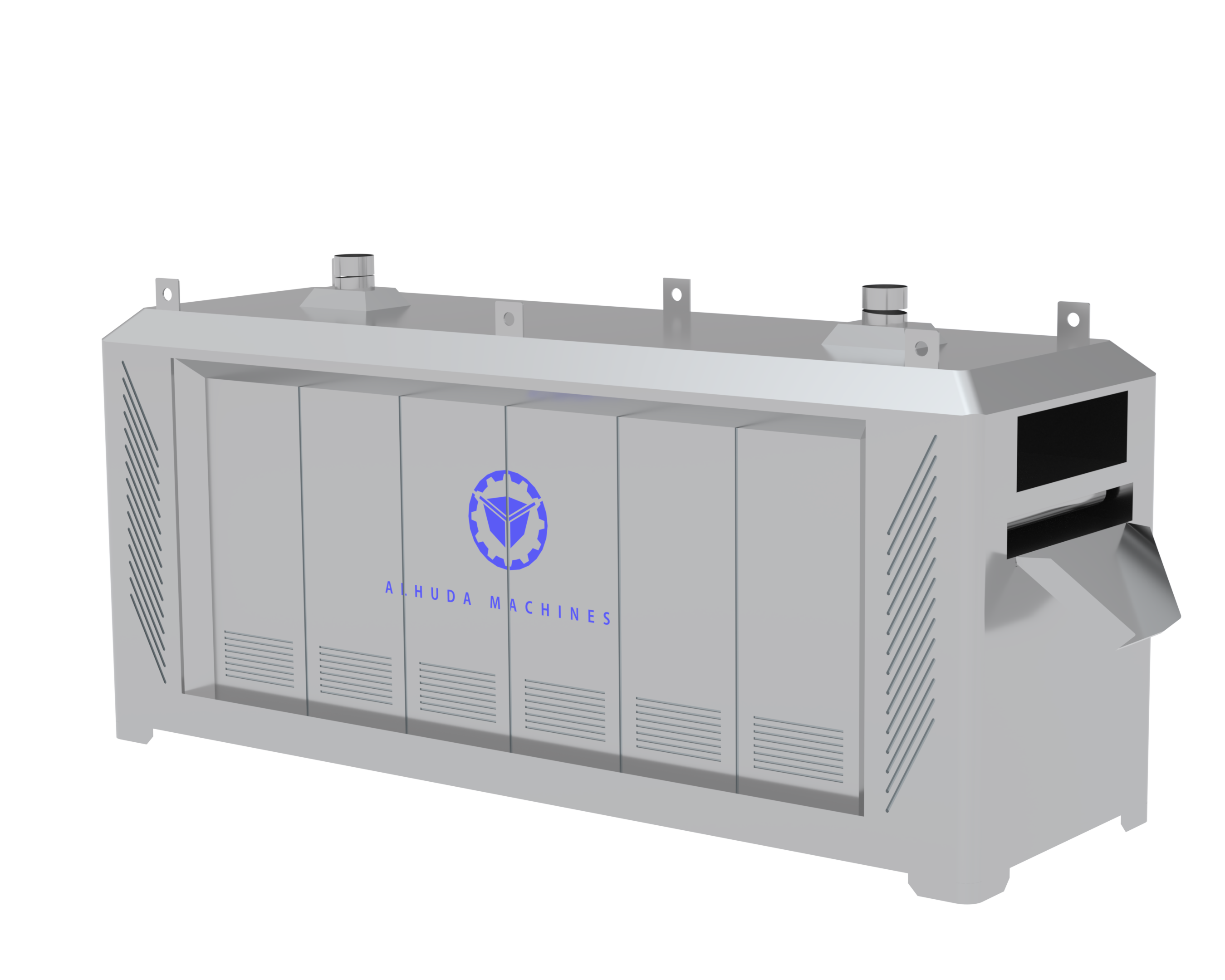

Hot air drying and roasting oven

Kusursuz kavurma ve verimli kurutma için gelişmiş teknoloji, Amerikan kalitesi ve Türk üretimiyle bir araya geliyor. Bu fırın, endüstriyel kavurma ve kurutma işlemleri için özel olarak geliştirilmiş olup, akıllı tasarım, eksiksiz ısı yalıtımı ve otomatik çalışma mekanizmalarıyla istikrarlı performans ve yüksek verimlilik sağlıyor. Mısır, buğday veya kavrulmuş tahıl cipsi üretim hatlarında kullanılır ve enerji ve verimlilik açısından en güçlü endüstriyel seçeneklerden biri olarak kabul edilir.

⚙️ Çalışma ve Mekanizma:

1️⃣ Profesyonel Amerikan Isıtma Sistemi

✔️ Fırın, 300°C'ye kadar sıcaklıklarda sıcak hava sistemiyle çalışır.

✔️ İsteğe bağlı güç kaynağı: dizel veya doğal gaz (LPG)

2️⃣ Otomatik Sıcaklık ve Hız Kontrolü

✔️ Konveyör ızgarasının hızını ayarlamak için her kat için bir invertör ile donatılmıştır.

✔️ Hassas hareket kontrolü için her kat için bağımsız bir motor ile donatılmıştır.

✔️ Esnek otomatik programlamaya sahip iki hassas sıcaklık saati

3️⃣ Verimli Hava Dağıtımı ve Isı Yalıtımı

✔️ Üstten ve alttan çift hava dağıtım mekanizması

✔️ Yan hava devridaim mekanizması

✔️ Güçlü pompa fanı + dahili emiş ve sirkülasyon fanı

4️⃣ Kolay Bakım ve Kullanım

✔️ İki çıkarılabilir ve geri çekilebilir ısıtma bölmesi

✔️ Ürün taşıyıcı ızgarası için otomatik temizleme mekanizması

✔️ Bağımsız olarak çıkarılabilir ve geri çekilebilir kontrol paneli

✔️ Otomatik arıza okuma sistemli elektronik dokunmatik ekran (uyarı mesajları, metin)

📐 Teknik Özellikler:

Model: THV-2025 SH-Z

Cihaz Numarası: 007

Üretim Kapasitesi: 300 kg/saat

Kızartma Sıcaklığı: 300°C'ye kadar

Güç Kaynağı: Dizel veya LPG (talep üzerine)

Elektrik Akımı: 380/220 VAC – 50 Hz – 10,5 kW

Fırın Boyutları:

◽ Uzunluk: 650 cm

◽ Genişlik: 150 cm

◽ Yükseklik: 220 cm

Malzeme: 304 paslanmaz çelik

Isı Yalıtımı: Her tarafta 12 cm kalınlığında fiberglas

🎯 Neden bu fırın?

✅ 7/24 istikrarlı performans ve yüksek verimlilik

✅ Kolay kurulum, temizlik ve bakım için akıllı tasarım

✅ Profesyonel güvenlik ve işletim sistemi

✅ Amerikan standartlarına uygun Türk üretim kalitesi

📍 Türkiye'de üretilmiştir - Avrupa kalite ve teknoloji garantisi. THV-2025 SH-Z - Profesyonel kavurma ve enerji tasarrufu için ideal endüstriyel çözüm.

Ligne de convoyage de copeaux

Efficient product transfer and precise feeding from oven to fryer – Hygienic and easy-to-clean design. This conveyor belt serves as a critical transfer stage in the production line, receiving the product directly from the oven after roasting or drying, and smoothly transferring it to the fryer feeder. The conveyor features a fully food-grade construction and a smart design that ensures hygiene and high operational efficiency.

➤ How it works:

1️⃣ Receiving product from the oven and feeding it to the fryer

✔️ The conveyor receives the product directly from the oven outlet

✔️ It efficiently transfers it to the fryer feeder without any product buildup or damage

2️⃣ Fully food-grade construction

✔️ Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion

3️⃣ Food-safe conveyor belt

✔️ Equipped with a high-quality PVC or food-grade plastic conveyor belt, designed to meet the highest food safety standards

4️⃣ Easy and automatic cleaning system

✔️ Features convenient cleaning access panels and automatic cleaning brushes

✔️ Ensures continuous cleaning without frequent downtime

5️⃣ Easy mobility and cleaning

✔️ Equipped with robust industrial casters for easy movement and cleaning as needed

📐 Technical Specifications: Model: THV-2025 SH-Z Power: 1.25 kW – 380/220VAC – 50Hz

Length: 300 cm

Width: 80 cm

Height: 300 cm

✅ Machine Number: 008

🎯 Why choose this conveyor belt?

✅ Designed 100% in accordance with international food safety standards

✅ Easy to clean and maintain – for reduced downtime and increased efficiency

✅ Reliably transports products gently, without damage

✅ Manufactured to European quality standards – ensuring long-term performance and durability

📍 THV-2025 SH-Z – The hygienic and efficient solution for transporting products from the oven to the fryer in modern production lines

Flavor Mixer Tank

Precise flavor preparation with indirect heating technology. The flavor cooking tanks are designed to ensure food flavors are prepared to the highest quality standards. They utilize an indirect heating system (double jacket) to provide even heating without affecting the flavor composition, resulting in an optimal flavor distribution in the final product. Advanced operating mechanism:

1️⃣ Professional design of the indirect heating system: The tank is constructed using double-jacket technology, allowing the water surrounding the tank to be heated instead of directly heating the flavor itself. This ensures the flavor retains its optimal quality without burning or altering its composition. With a heating capacity of up to approximately 200 liters, it is ideal for large production lines. A level indicator monitors the hot water level in the tank to ensure smooth and continuous operation.

2️⃣ Durable and robust construction for industrial environments: Made entirely of food-grade 304 stainless steel, ensuring high resistance to corrosion and easy cleaning and sterilization. The base frame is made of galvanized steel and covered with stainless steel for added durability and protection. The tanks and pump are mounted on a single frame for easy installation and maintenance. Heavy-duty casters facilitate movement and cleaning, allowing for easy transport within production lines.

3️⃣ Precise temperature control system: Equipped with a digital temperature gauge for continuous monitoring of the hot water temperature inside the tank, ensuring precise control of the heating process. A uniform heat distribution system prevents hot spots within the flavor, guaranteeing a consistent final product. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 3.75 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 230 cm

Width: 130 cm

Height: 170 cm

✅ Machine Number: 009

✅ Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Features of the Flavor Cooking Tank:

✔️ Double-jacketed design for indirect heating, preserving flavor quality.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with a water level indicator and a temperature gauge for precise temperature control.

✔️ Robust frame made of galvanized steel for durability and longevity.

✔️ Equipped with wheels for easy movement and cleaning, making it suitable for various production lines.

✔️ Large capacity of up to 250 liters, making it ideal for large-scale industrial production.

💡 The perfect solution for preparing flavors with the highest precision and quality!

Flavor pump

Advanced technology for precise and efficient flavor dispensing. The flavor pump is a key component of any chip production line, precisely dispensing and distributing flavor through an innovative alternating suction and pumping system. This ensures optimal flavor usage and consistent flavor coverage on the final product. Advanced operating mechanism:

1️⃣ Alternating suction and pumping technology (advanced American system): The pump utilizes an alternating suction and pumping system, a modern American technology that precisely controls flavor flow and minimizes waste, resulting in highly efficient and economical flavor usage.

2️⃣ Powerful motor and durable construction: Equipped with a robust geared motor, connected to a high-quality European-made aluminum pump, ensuring reliable performance and consistent pumping speed. The pump body is made of solid European-grade aluminum, making it corrosion-resistant and capable of continuous operation.

3️⃣ Precise electronic control of flavor quantity: The amount of flavor dispensed is electronically controlled via an inverter, allowing adjustment of the pumping rate according to the product type and production requirements.

4️⃣ Practical design and easy maintenance: The pump is mounted on a food-grade stainless steel 304 frame, providing stability, ease of movement, and easy cleaning. The connection between the motor and the pump uses a flexible rubber coupling, facilitating quick maintenance and disassembly. It features a Spanish-made food-grade silicone hose, ensuring safe transport of the flavor without affecting its quality. The unit is equipped with sturdy casters for easy movement and cleaning, making it ideal for use in industrial production lines. Technical Specifications

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Power: 1.125 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 80 cm

Width: 60 cm

Height: 80 cm

✅ Machine Number: 010

✅ Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High-quality manufacturing according to European standards.

✔️ Advanced American technology for precise flavor dispensing and minimal waste.

✔️ Powerful geared motor and European-made aluminum pump for consistent performance.

✔️ Precise electronic control system for flavor dispensing volume via inverter.

✔️ Practical design with a food-grade 304 stainless steel base and casters.

✔️ Easy maintenance thanks to a rubber coupling for quick assembly and disassembly.

✔️ Equipped with a Spanish-made food-grade silicone hose for safe flavor transfer.

💡 The ideal solution for efficient flavor dispensing and ensuring consistent taste for every chip.

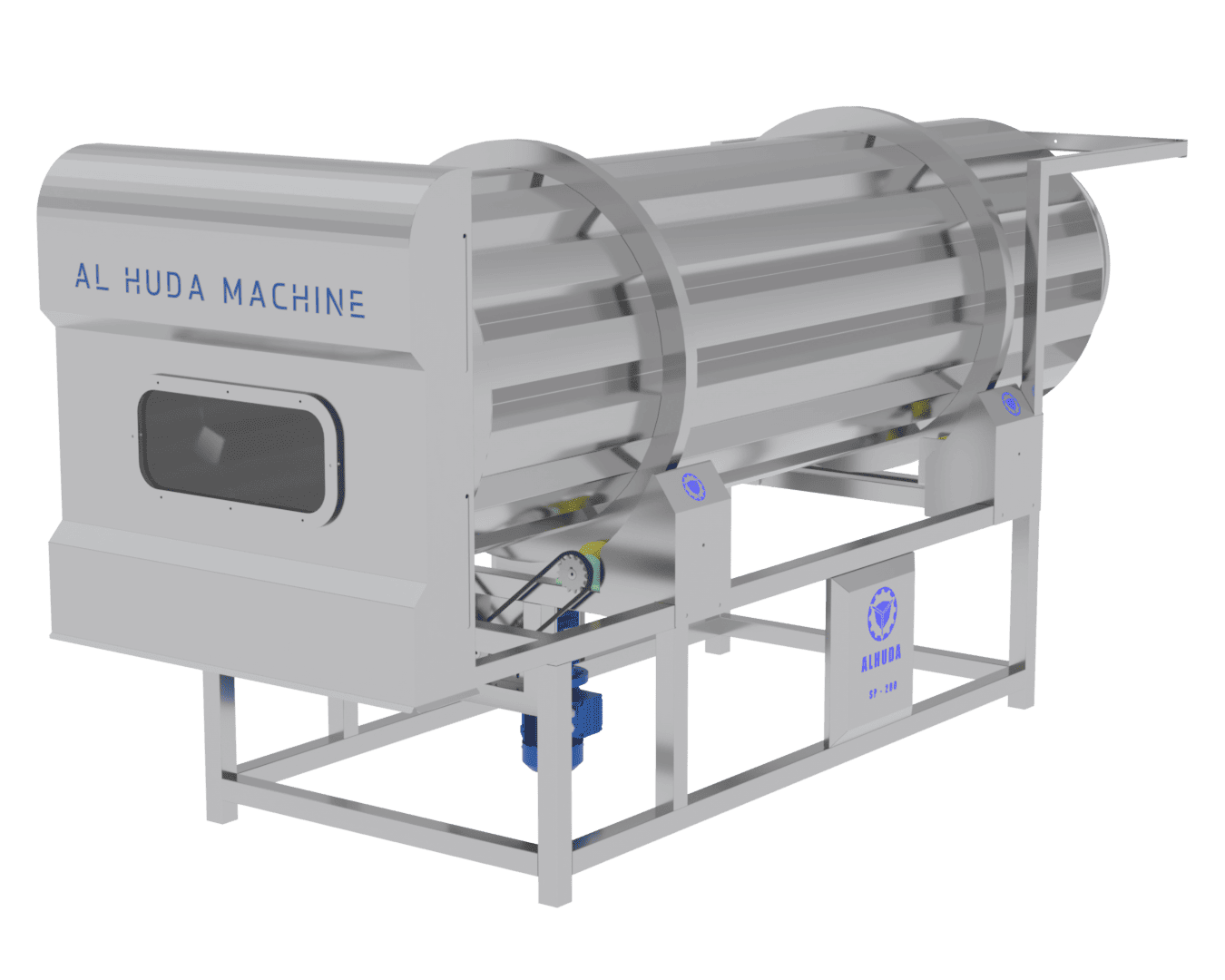

Flavor coating cylinder

Professional flavor distribution – slow rotation, perfect coating, and consistent flavor quality in every chip! The cylindrical seasoning unit is the final and crucial stage in the potato chip production line. It ensures that the chips are coated with their distinctive flavor evenly and precisely, guaranteeing a delicious taste and a professional appearance for the final product.

➤ How it works in detail:

1. ✅ Rotating food-grade cylinder: Made entirely of food-grade stainless steel (304) for hygiene and easy cleaning. It rotates at a slow, calculated speed to ensure optimal flavor distribution without damaging the chips.

2. ✅ Electronic speed control: Equipped with a modern inverter for precise control of the cylinder's rotation speed, tailored to the type of chip and its sensitivity.

3. ✅ Advanced flavor sprayer: Features a modern, adjustable American-made flavor sprayer. It allows for a smooth and even application of flavor while the chips rotate inside the unit.

4. ✅ Anti-clumping design: Special protrusions inside the unit prevent flavor from clumping or sticking, ensuring an even distribution across all the chips.

5. ✅ Adjustable chip dwell time: The time the chips spend inside the cylinder can be adjusted according to the desired flavor intensity and coating thickness.

6. ✅ Impurity removal system: Equipped with a special system to remove very small particles or unwanted crumbs during the seasoning process, maintaining the quality of the final product.

7. ✅ Easy mobility and cleaning: Features a stylish chrome cover and durable wheels for easy movement and cleaning after use.

➤ Technical Specifications:

Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 120 cm

Height: 150 cm

Machine Number: 011

Model: THV-2025 SH-Z

✅ Country of Origin: Turkey – High-quality industrial product, manufactured according to European standards. Robust design and high operational efficiency.

➤ Features of the Flavoring Drum:

Optimal flavor coating to ensure a consistent flavor and perfect texture for every chip.

Smart design prevents powder buildup and clumping inside the drum. High-performance flavor sprayer for even distribution without waste.

Easy calibration and cleaning for faster maintenance times. Ideal for all types of potato chips and other crispy snacks.

Now you have detailed and comprehensive explanations for every component of a Cheetos, Pringles, or regular potato chip production line.

Electrical parts and control panels

Circuit breakers: Schneider brand

Contactors: Schneider brand

Control panel: Delta

Inverters: Delta

Motors: GAMAK

Gearboxes: YILMAZ

Or as per customer request

Basic information

Al-Huda's oven-based Cheetos chip production line is the ideal solution for producing high-quality Cheetos chips using an oven-roasting system. This line combines European technology with Turkish manufacturing expertise to meet the needs of medium and large-scale production facilities.

⚙️ Production Line Stages:

1️⃣ Dry Ingredients Mixer:

✔️ Corn flour is mixed with other ingredients such as flavorings and additives using a high-efficiency industrial mixer.

2️⃣ Extrusion:

✔️ The mixture is fed into an extruder, which shapes the dough into the desired Cheetos shape using precise extrusion technology.

✔️ Temperature and pressure are controlled to ensure the perfect texture.

3️⃣ Oven Roasting System:

✔️ In this stage, the product is transferred to an oven that uses hot air to quickly and precisely dry and roast the Cheetos chips.

✔️ The oven operates at high temperatures up to 300°C to achieve a golden color and a distinctive crispness.

4️⃣ Cooling System:

✔️ After exiting the oven, the Cheetos chips are rapidly cooled using a special cooling system to maintain their crisp texture.

✔️ This system helps prevent moisture buildup and prepares the final product for flavoring.

5️⃣ Seasoning:

✔️ After cooling, seasonings and flavors are added using a special device to ensure even distribution across all the chips.

🎯 Why choose the oven-based Cheetos chip production line? High energy efficiency: The use of a hot air oven helps save energy while guaranteeing high product quality. Consistent quality: The line operates according to European standards, using stainless steel materials for corrosion resistance and durability. Ease of operation and maintenance: This production line is designed for ease of use and maintenance, thanks to its advanced systems and user-friendly software. Versatile product range: The line can be customized to produce various types of Cheetos, depending on the desired product shape and level of crispiness. Quality assurance: All components are regularly tested to ensure the customer receives optimal performance. At Al Huda, we take full responsibility for any deviations from specifications and conditions. The production line is tested at our Al Huda factory. If the customer is not satisfied, they are entitled to a full refund.

🔧 Turkish-made with German technology, with over twenty years of experience; our products are certified with international quality standards.

💡 Al Huda – Generations of experience in the manufacturing industry, innovation for the present, and development for the future.

📐 Production line specifications: Total length: 23 meters; Width: 3 meters; Required floor space: 300 m²

🌟 Feel free to contact us with any inquiries. Al Huda – your ideal choice. For any modifications or additional details, please contact us, and we will provide you with all the information you need.