Pellet chips frying line, production capacity 600 kg

🔹 Pellet Chip Frying Line – Producing Delicious, High-Quality Crisps. The Pellet Chip Frying Line is an integrated industrial system used to convert ready-made pellet granules into crunchy chips. This process involves several steps, including:

1. Pellet Feeding: The raw pellets are fed to the fryer on a regular basis.

2. Frying: The pellets are fried in hot oil inside an automatic fryer, giving them a delicious taste and crispy texture.

3. Oil Removal: Excess oil is filtered to produce a healthier product.

4. Cooling: The chips are gradually cooled to maintain their crunch.

5. Seasoning: Add flavors as desired (cheese, ketchup, pepper, etc.).

6. Packaging: The chips are packed in airtight bags to preserve taste and quality.

✅ The line operates automatically.

✅ Suitable for producing various pellet shapes (corn, potatoes, wheat, etc.)

✅ Available in various production capacities starting from 600 kg/hour

The line consists of the following parts

1_Product conveyor line

2_Fryer feeder

3_Fryer

4_Oil removal shaker

5_Chip cooling line

6_Spice refilling device

7_Seasoning refilling cylinder

Conveyor belt with product collection basin

The smart solution for conveying raw pellets to the fryer – automatic, efficient, and easy to feed! This conveyor is an essential component of the production line, automatically transporting raw pellets from the collection tank to the fryer feeder smoothly, with a capacity of up to 100 kg. It is designed for stable performance and ease of use, while ensuring quick cleaning and maintenance.

⚙️ Advanced Operation Mechanism:

1️⃣ Fast and smooth automatic conveying

✔️ Intelligently links stages to ensure a continuous flow of product to the fryer.

✔️ Capacity of up to 100 kg, making it ideal for medium and large production lines.

✔️ Design facilitates feeding into the fryer without manual intervention.

2️⃣ Hygienic and Practical Design

✔️ Made entirely of food-grade 304 stainless steel to ensure hygiene and corrosion resistance.

✔️ Conveyor belt made of PVC or food-grade plastic designed for efficient and pollution-free material transfer.

✔️ Equipped with movable wheels for easy cleaning and movement within the laboratory.

3️⃣ Continuous cleaning with minimal effort

✔️ Built-in cleaning holes.

✔️ Equipped with automatic cleaning brushes to ensure the conveyor remains clean during operation.

✔️ Design facilitates washing and periodic maintenance.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

Length: 300 cm

Width: 80 cm

Height: 200 cm

✅ Machine Number: 001

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose this conveyor?

✔️ Automatic conveying system reduces the need for manual intervention and speeds up production.

✔️ Large capacity with a fully hygienic design.

✔️ Easy to clean and move around the plant.

✔️ Stable performance with low energy consumption.

🔹 The ideal choice for efficiently and high-quality conveying of raw pellets to the fryer in a clean and safe production environment!

Billet material feeder

Accurate and Regular Feeding into the Fryer – Large Capacity Tank, Advanced Vibrator, and Optimal Product Flow Control! The pellet feeder is one of the key components in ensuring a consistent and precise flow of raw materials into the frying tank. Thanks to a large 100 kg tank and an advanced industrial vibrator, this unit ensures continuous and consistent feeding without interruption or congestion in the production line.

⚙️ Advanced Operation Mechanism:

1️⃣ Spacious Material Collection Tank

✔️ 100 kg main tank for storing sufficient quantities of pellets.

✔️ Streamlined design allows for smooth discharge of materials into the frying tank.

2️⃣ Professional Vibrator Flow Control System

✔️ Equipped with a premium Turkish or Italian industrial vibrator – variable speed for precise pellet flow control.

✔️ Contributes to a consistent and even distribution of materials throughout the production line.

✔️ Allows for easy and flexible adaptation to varying production quantities.

3️⃣ Durable, food-grade construction

✔️ Made entirely of 304 food-grade stainless steel – rust-resistant and easy to clean.

✔️ Practical design supports continuous operation in industrial environments.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 3.75 kW

✅ Dimensions:

Length: 130 cm

Width: 100 cm

Height: 160 cm

✅ Machine Number: 002

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose the THV-2024PV-Z pellet feeder?

✔️ Large capacity eliminates frequent feeding and speeds up production.

✔️ Variable-speed vibrator provides precise control over the quantity and timing of material flow.

✔️ High-quality manufacturing materials ensure food safety and easy cleaning.

✔️ Compact and practical design that fits all modern production lines.

🔹 The ideal choice for consistent and accurate feeding into the fryer, ensuring product quality and production line continuity!

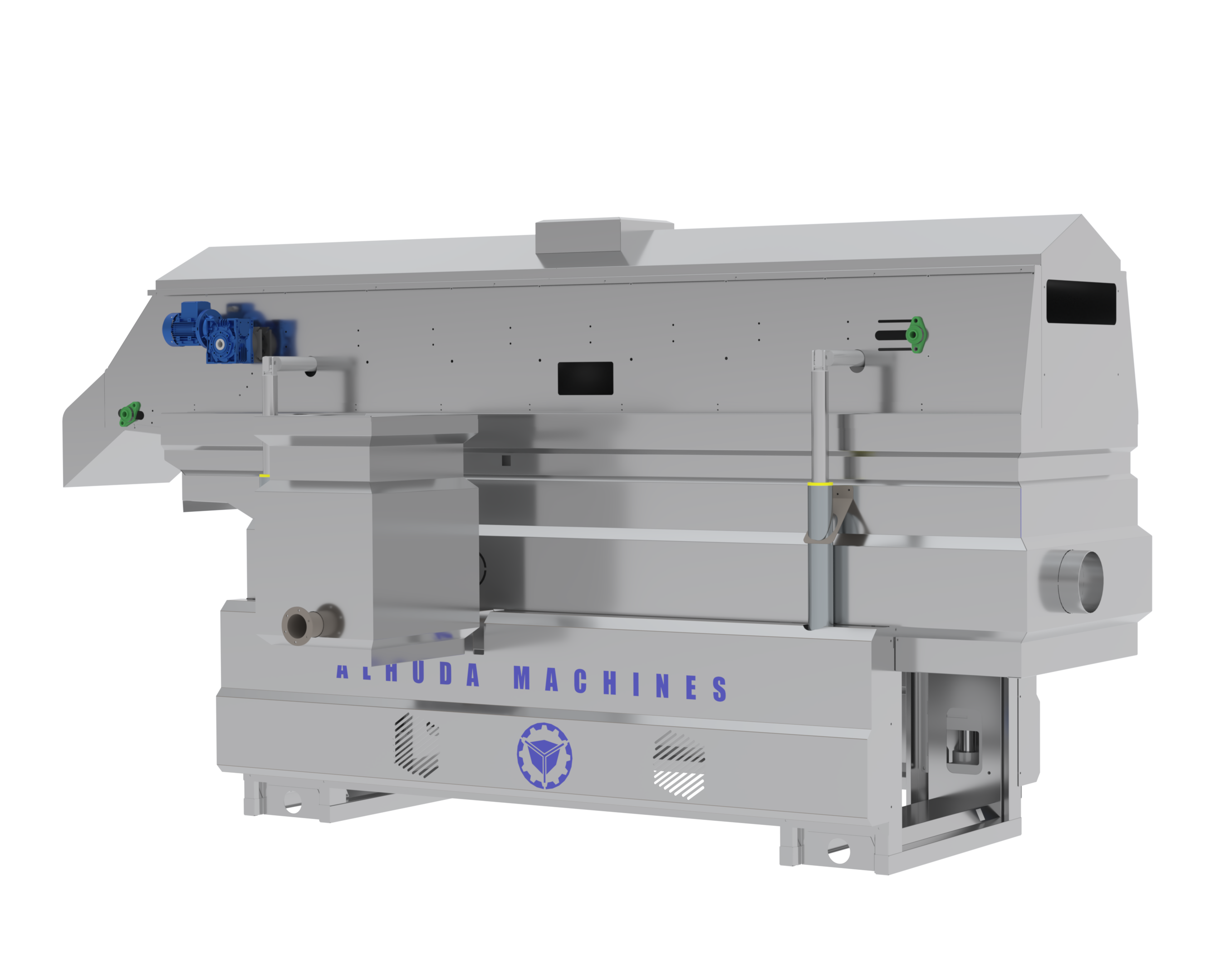

The fryer

Advanced technology for perfect frying around the clock – even cooking, energy savings, and ease of operation! This fryer is specially designed to operate 24 hours a day, with meticulous engineering to ensure that the chips pass smoothly through the oil and are quickly and precisely fried. Thanks to its intelligent structure and fully insulated fire chamber, this fryer is one of the best solutions for making chips with high efficiency and superior quality.

⚙️ Advanced mechanism:

1️⃣ Fast and balanced frying in less than 15 seconds

✔️ The frying tub is filled with oil, through which the chips continuously pass.

✔️ The chips are regularly immersed and stirred in the hot oil to achieve the desired degree of doneness.

✔️ The cooked chips are transferred to the end of the fryer in just 15 seconds to ensure crispy taste and consistent quality.

2️⃣ Automatic Lifting and Built-in Oil Removal System

✔️ After cooking, the chips are gradually lifted through a built-in vibrating mesh conveyor to remove excess oil as the first stage of drying.

✔️ Reduces the amount of retained oil and preserves the product's flavor.

3️⃣ Safe and Efficient Internal Heating Chamber

✔️ Equipped with a fire chamber built into the fryer to heat the oil quickly and efficiently.

✔️ Operates with a diesel or gas burner, depending on the customer's preference.

✔️ Fully insulated using 15 cm thick fiberglass on all sides to maintain temperature and save energy.

✔️ Safe design protects workers and reduces heat loss.

4️⃣ High-quality materials and ease of cleaning

✔️ Full body made of 304 food-grade stainless steel for corrosion resistance and ease of washing.

✔️ Design for easy access to all internal parts for maintenance and cleaning.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 10.5 kW

✅ Dimensions:

Length: 550 cm

Width: 130 cm

Height: 200 cm

✅ Machine Number: 003

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose the THV-2024PV-Z fryer?

✔️ Continuous, 24-hour production.

✔️ Perfect cooking and efficient primary oil removal.

✔️ Safe, insulated fire chamber for energy savings and safety.

✔️ Flexible fuel choice between gas or diesel.

✔️ Professional design for easy maintenance and cleaning.

🔹 The perfect choice for frying chips efficiently, with perfect tenderness and high operational safety in a professional production environment!

Oil tanks - 2

Intelligent Oil Storage and Feeding Control – Dual insulation and heating system for highly efficient frying oil management! The two oil tanks are designed to refill the fryer with fresh oil when needed and to store used oil for re-filtration or replacement. Each tank has a capacity of 320 liters and operates within an integrated system to maintain oil temperature and stable performance, especially in cold weather conditions.

⚙️ Integrated Operation Mechanism:

1️⃣ Dual Feeding and Storage System

✔️ The first tank is responsible for automatically refilling the fryer with fresh oil when needed.

✔️ The second tank is dedicated to collecting used oil after frying, prior to filtering or disposal.

2️⃣ Double Jacket Design with Smart Heating System

✔️ The tanks are designed with a double jacket to be filled with water, allowing the oil to be maintained at room temperature and prevent freezing, especially in winter.

✔️ Each tank is equipped with two efficient electric heaters to ensure optimal temperature.

✔️ Wall thickness: 3 mm, with 3-inch diameter tube bases for stability and strength.

3️⃣ Dual Pump Oil Distribution System

✔️ Equipped with two pumps: one to feed the fryer, and the other to transfer the used oil to the filtration system.

✔️ Ensures a smooth and consistent flow without manual intervention, enhancing the complete automation of the process.

4️⃣ Hygienic Construction and High Quality

✔️ Tanks are made entirely of food-grade 304 stainless steel, resistant to corrosion and rust.

✔️ Design facilitates maintenance and cleaning, extending service life.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 3.75 kW

✅ Dimensions per tank:

Length: 250 cm

Width: 120 cm

Height: 150 cm

✅ Part Number: 004

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose THV-2024PV-Z oil tanks?

✔️ Large storage capacity eliminates the need for frequent refills.

✔️ Dual heating system maintains oil fluidity under all conditions.

✔️ Powerful pumps for efficient and rapid oil transfer.

✔️ Hygienic and durable design compliant with food standards.

✔️ A smart and safe solution for fryer feeding and used oil management.

🔹 The perfect choice for organizing the frying process and ensuring continuous performance without interruption or waste!

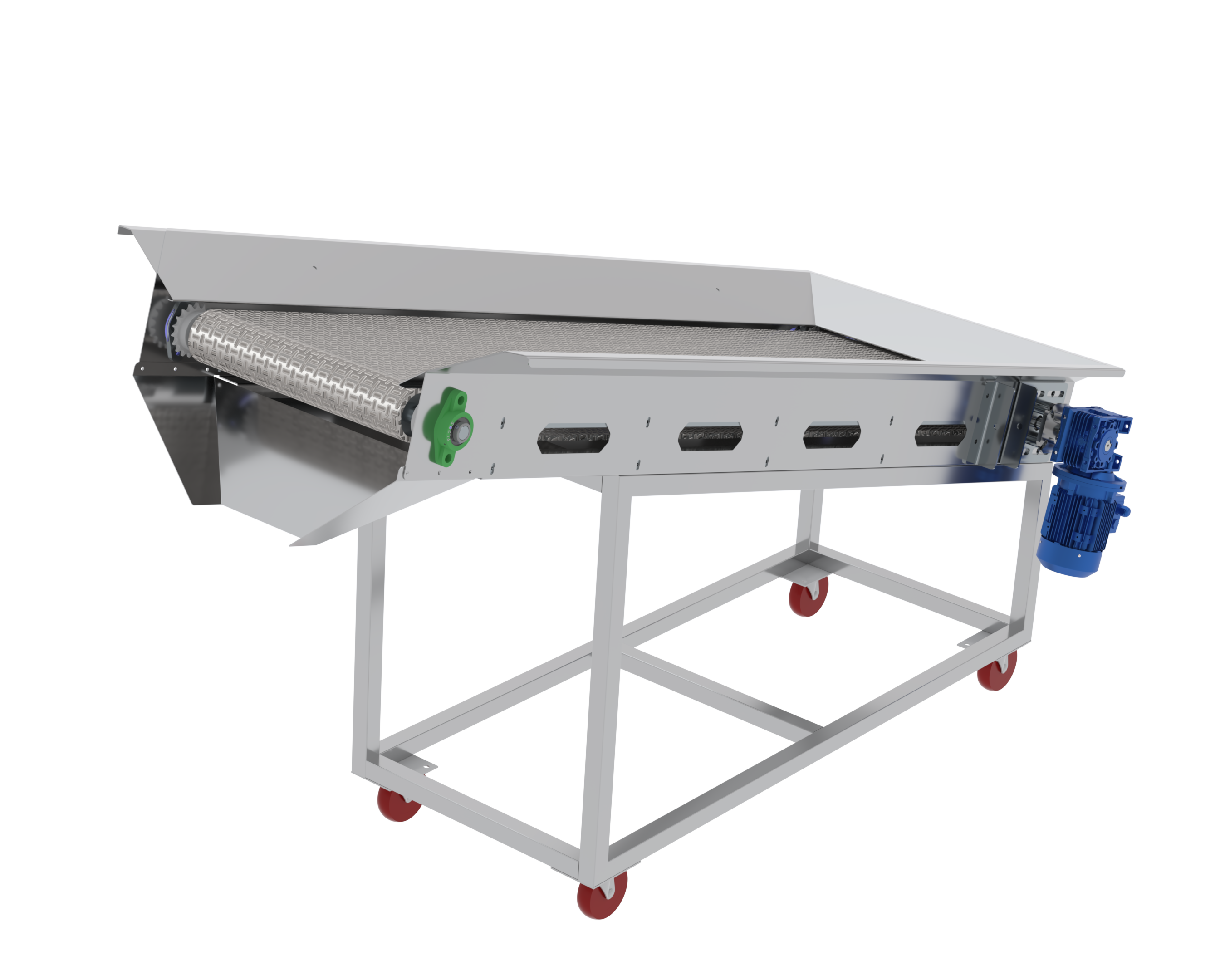

Oil drying vibrator

Effective drying, perfect consistency, and consistent performance – the smart solution for removing excess oil after frying! The oil drying shaker is one of the most important post-frying stages in the potato chips production line. It removes excess oil from fried potato chips using high-frequency vibration, ensuring a crispy, oil-free product while preserving the quality and appearance of the chips.

⚙️ Smart working mechanism:

1️⃣ High vibration for effective drying

✔️ Operates with a high-frequency vibration system that efficiently removes residual oil from the surface of the chips.

✔️ Prevents fried potato chips from sticking together.

✔️ Reduces the oil content of the final product and preserves its natural taste.

2️⃣ 4-stage progressive motion system

✔️ A four-stage progressive conveyor works in a carefully coordinated motion to filter the oil gradually and evenly.

✔️ Provides smooth oil drainage without damaging the chips.

3️⃣ Hygienic and Safe Design

✔️ Made entirely of food-grade 304 stainless steel to ensure product safety and easy cleaning.

✔️ Corrosion and moisture resistance, making it suitable for continuous use in an industrial environment.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 4.5 kW

✅ Dimensions: Length: 300 cm, Width: 100 cm, Height: 140 cm

✅ Machine Number: 005

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose the THV-2024PV-Z Oil Drying Shaker?

✔️ Effectively drains excess oil to ensure the quality of the final product.

✔️ Prevents chip adhesion and breakage during transportation and processing.

✔️ A progressive motion system ensures stable and balanced performance.

✔️ A hygienic and durable design that fits advanced production lines.

✔️ Controlled power consumption and high industrial performance.

🔹 The ideal choice for purifying chips from excess oil and maintaining quality in every piece!

Cooling conveyor line

Balanced Cooling and Perfect Seasoning Preparation – Smooth Transfer and Consistent Quality Before the Flavoring Stage! This grid line serves as a crucial transition between frying and seasoning, gently cooling the chips and providing a "resting" period before they enter the seasoning tank. This system ensures the chips maintain their ideal texture and prepare them for optimal flavor reception.

⚙️ Efficient Working Mechanism:

1️⃣ Chip Cooling and De-Heating

✔️ The line cools the chips after they leave the shaker and before entering the seasoning tank.

✔️ This gives the chips sufficient time to lose excess heat, promoting better flavor bonding.

✔️ Maintains a crisp texture and prevents chip deformation.

2️⃣ Smooth Transfer to the Seasoning

✔️ Streamlined design ensures chips move easily into the seasoning tank.

✔️ Prevents stacking or damage during transportation and maintains an even product distribution.

3️⃣ Hygienic and Strong Construction Materials

✔️ The entire body is made of food-grade 304 stainless steel, resistant to rust and moisture.

✔️ Easy to clean and maintain daily.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 1.25 kW

✅ Dimensions:

Length: 300 cm

Width: 70 cm

Height: 100 cm

✅ Machine Number: 006

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why Choose This Grid Line?

✔️ Ideally prepares chips for the seasoning stage.

✔️ Reduces product temperature without the need for complex cooling systems.

✔️ Simple and efficient design made from food-grade materials.

✔️ Stable performance and easy cleaning and operation.

🔹 The perfect choice for ensuring consistent flavor and quality of chips before seasoning!

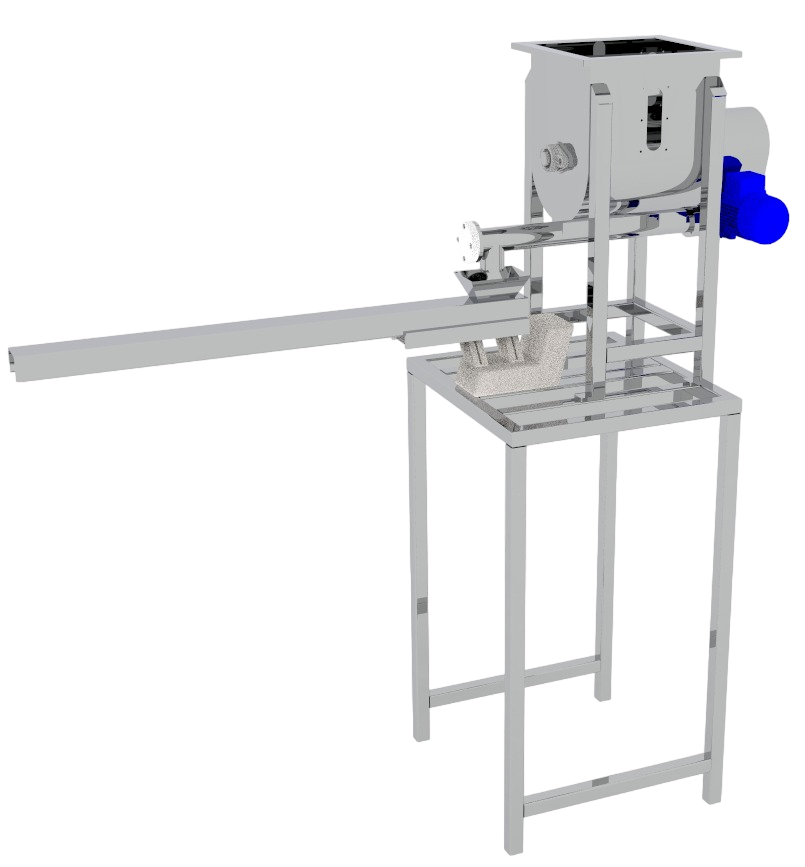

Flavoring device – spice

Precise control of flavor quantity – perfect distribution and professional packaging of chips! This device is specially designed to distribute flavor powder evenly and efficiently onto chips. It combines a mixing, stirring, and spiral feeding system supported by precise electronic control. It ensures uniform coverage of each chip with a rich, attractive flavor.

⚙️ Smart working mechanism:

1️⃣ Integrated feeding and stirring system

✔️ A tank equipped with a continuous mixing and stirring device for the flavor powder to prevent clumping and ensure uniformity.

✔️ A horizontal feeding screw delivers the flavor to the spray vibrator.

✔️ Equipped with an inverter that allows precise control of the amount of spices dispensed.

2️⃣ Electronic control and precise calibration

✔️ Equipped with an electronic circuit for complete control of the flavor quantities distributed according to the production line speed.

✔️ Easily adjust the amount of flavor to ensure balanced packaging without waste.

3️⃣ Efficient design for optimal chip packaging

✔️ Ergonomic design ensures even distribution of flavor powder throughout the chips.

✔️ Gives the final product a balanced taste and attractive appearance.

4️⃣ Hygienic and high-quality manufacturing

✔️ The entire body is made of 304 food-grade stainless steel, corrosion-resistant and easy to clean.

✔️ Ideal for continuous operation in industrial production environments.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 2.25 kW

✅ Dimensions:

Length: 140 cm

Width: 80 cm

Height: 160 cm

✅ Machine Number: 007

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose the THV-2024PV-Z Flavoring Machine?

✔️ Perfect distribution of flavors in precise quantities.

✔️ Integrated electronic control with easy adjustment and calibration.

✔️ Practical design supports continuous production.

✔️ Uniform packaging of chips without clumping or uneven taste.

🔹 The smart choice for a delicious, balanced, and professionally distributed flavor on every chip!

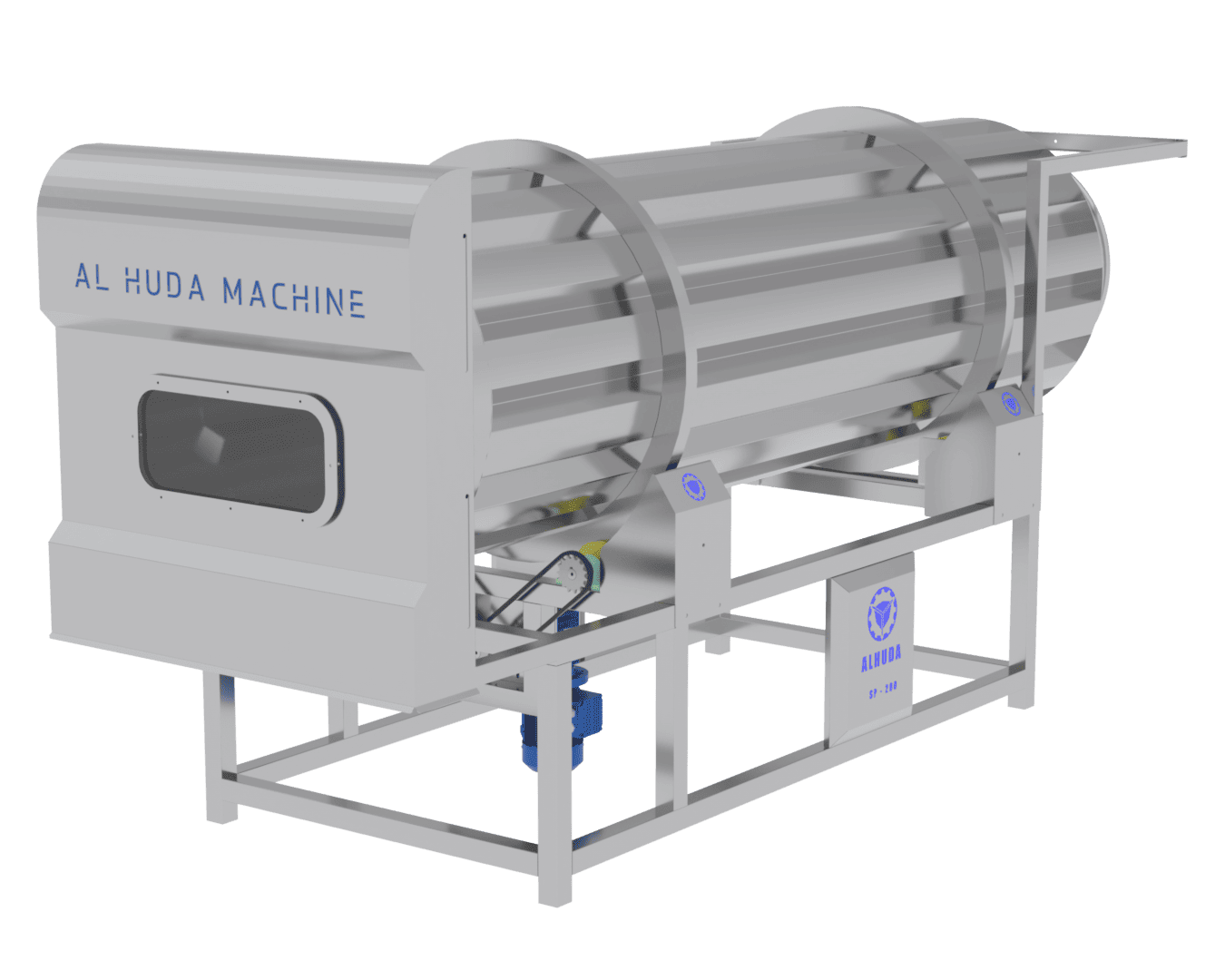

Flavor coating cylinder

Perfect Flavor Distribution – Slow Rotation, Even Coverage, and Precise Electronic Control! The seasoning device is the final stage in the chip production line. The flavor is sprayed and evenly distributed onto the chips via a precision-engineered rotating drum, with advanced electronic control systems to adjust the time and amount of flavor.

⚙️ Advanced Mechanism:

1️⃣ Rotating Drum with Deliberate Rotation

✔️ A rotating drum made of food-grade 304 stainless steel that slowly rotates the chips.

✔️ This rotation helps distribute the flavor evenly without clumping or accumulating.

✔️ Equipped with specially designed internal scales to prevent spice buildup.

2️⃣ Precise Flavor Spray – Made in the USA

✔️ Equipped with an advanced American-designed flavor sprayer that can be calibrated as needed.

✔️ Ensures precise and effective dispersion of flavor powder in a smooth, even manner.

3️⃣ Electronic Inverter Control

✔️ Equipped with an inverter to control the rotation speed of the seasoning and determine the time the chips pass through it according to the product type.

✔️ Easily adjust settings for optimal results.

4️⃣ Impurity Ejection System to Improve Product Quality

✔️ Equipped with a mechanism to eject unwanted impurities and very small chips that may result from the rotation process.

✔️ This system contributes to ensuring a clean, consistent, and high-quality final product.

5️⃣ Easy Mobility and Cleaning

✔️ Equipped with a chrome cover at the product outlet for additional protection and control of emptying.

✔️ Equipped with movable wheels for easy transportation and periodic cleaning.

📏 Technical Specifications:

✅ Voltage: 380/220VAC – 50Hz

✅ Power: 3.75 kW

✅ Dimensions:

Length: 300 cm

Width: 120 cm

Height: 150 cm

✅ Machine Number: 008

✅ Model: THV-2024PV-Z

✅ Country of Origin: Turkey

💡 Why choose the THV-2024PV-Z Seasoning Machine?

✔️ Even flavor distribution throughout the chips.

✔️ Advanced flavor atomizer with high precision calibration.

✔️ Intelligent ejection system for impurities and chips

Electrical parts and control panels

Schneider breakers

Schneider contactors

Delta control panel

Delta inverters

Gamak motors

Yilmaz gearboxes

Or as per customer request

Basic information

🏭 Pellet Chips Frying Production Line: Advanced technology for producing delicious, high-quality crisps with excellent production efficiency. The Pellet Chips Frying Production Line is one of the latest industrial solutions developed by Al-Hoda Company to produce crispy, delicious chips from pellet raw materials. This process is carried out through an integrated system that includes frying, oil removal, cooling, seasoning, and packaging, according to the highest quality and food safety standards.

⚙️ Working Mechanism:

1️⃣ Raw Pellet Feeding Unit

✔️ Ensures a balanced and regular feeding of pellet raw materials to the line.

2️⃣ Automatic Frying Machine

✔️ Continuous frying system distributes heat evenly.

✔️ Gives the product a consistent golden color and perfect crunch.

3️⃣ Oil Removal Unit

✔️ Reduces excess oil after frying.

✔️ Contributes to improving the nutritional value of the product and increasing its quality.

4️⃣ Cooling and Conveying System

✔️ Gradually cools chips after frying to maintain crunch.

✔️ Smoothly transports them to the seasoning unit.

5️⃣ Seasoning and Flavoring Unit

✔️ Adds flavors and seasonings as desired.

✔️ Equipped with a coverage control system to ensure consistent flavor.

6️⃣ Packaging Machine

✔️ Automatic packaging into airtight bags.

✔️ Ensures product protection from moisture and flavor preservation.

📐 Technical Specifications: Full Line Length: 20 meters Approximate Line Width: 3 meters Required Operation Area: 300 square meters Production Capacity: (600 kg/hour to 1400 kg/hour)

⭐ Production Line Features:

✅ Continuous operation with fully automated control – reduces waste and increases efficiency.

✅ Economical design that saves energy and oil.

✅ Flexibility in using multiple pellet types (corn, wheat, potatoes, rice, etc.).

✅ Excellent final product quality in terms of texture, taste, and packaging.

✅ Easy operation, cleaning, and maintenance. Final product applications: This line can produce a wide range of pellet chips:

🔸 More than 30 different pellet shapes can be fried.

🏅 Why choose Al-Huda Company?

🔹 Turkish manufacture with German technology spanning over 20 years.

🔹 International quality certifications.

🔹 Comprehensive warranty and full on-site testing of the line before delivery.

🔹 Generations of experience in the industry, constantly innovating for the future. Would you like a customized quote for this line?

📩 Don't hesitate to contact us, and we will provide you with all the technical advice and a detailed catalog.