Half-fried French fries production line

🥔✨ Frozen French Fries Production Project – The Investment of the Future

🔹 Project Overview

A frozen French fries production project is one of the most successful and profitable business ventures currently available.

It is based on a very high consumer demand from various customer segments, including restaurants, supermarkets, hypermarkets, and even food distribution companies.

💡 Why is this project profitable?

📈 Constantly growing demand: Over 80% of restaurants rely on frozen French fries as a staple ingredient, consuming huge quantities every month.

🏙️ Massive consumption rates:

In small cities ➝ tens of tons per month.

In medium-sized and large cities ➝ hundreds of tons per month.

🛒 Diverse customer base:

Fast food and upscale restaurants.

Hypermarkets and supermarkets.

Food retail and distribution companies.

🌍 Low local competition: Few specialized factories compared to the high demand.

🚢 High import costs: Importing increases the price due to shipping and customs fees, making local production more profitable.

⚙️ Al-Huda's Frozen French Fries Production Line

Al-Huda offers you the best frozen French fries production line, designed according to the highest European quality standards, to operate efficiently 24/7.

✨ Key features of the line:

1. 🌀 High-quality starch removal system ➝ to ensure crispy, golden-brown fries.

2. 🔥 Frying machine with a boiler system:

Oil is heated outside the fryer.

Maintains the desired temperature.

Extends oil lifespan and prevents spoilage. 3.

🔪 European-made potato slicer from FAM (Belgium) ➝ For precise cutting and uniform potato shapes.

4. 🛡️ Made entirely of food-grade stainless steel (304):

Rust-resistant.

Easy to clean and sanitize.

Ensures the highest standards of food safety and hygiene.

🎯 Why choose Al Huda's production line?

✔️ Modern design, developed with European technology.

✔️ Operates 24/7 with high production capacity.

✔️ Final product quality that rivals and surpasses imported products.

✔️ A strong investment opportunity with consistent profits.

🏆 In Summary

Al Huda's semi-fried potato production line is not just a piece of equipment; it's a strategic investment opportunity in a rapidly growing food sector with ever-increasing demand.

🔑 The smart investor seizes this opportunity now, before the market becomes saturated with competitors.

The line consists of the following parts

1. Integrated conveyor with potato collection basin

2. Brush-type potato peeling machine

3. Inspection and monitoring conveyor for unwanted potatoes

4. Potato collection basin and water washing

5. Potato sorting vibrator

6. Slicer feeder

7. Potato cutting machine

8. Potato fingers collection basin and water washing

9. Unwanted finger sorting machine

10. Starch extraction, sugar adjustment, and blanching machine for potato fingers

11. Vibrator for dewatering and drying potato fingers

12. Tunnel for drying potato fingers from water and moisture before frying

13. Continuous frying machine

14. Vibrator for extracting oil from potato fingers

15. Inspection conveyor for potato fingers

16. Spiral-shaped conveyor for cooling potato fingers

17. 40-degree cooling and shock tunnel

18. Packaging machine

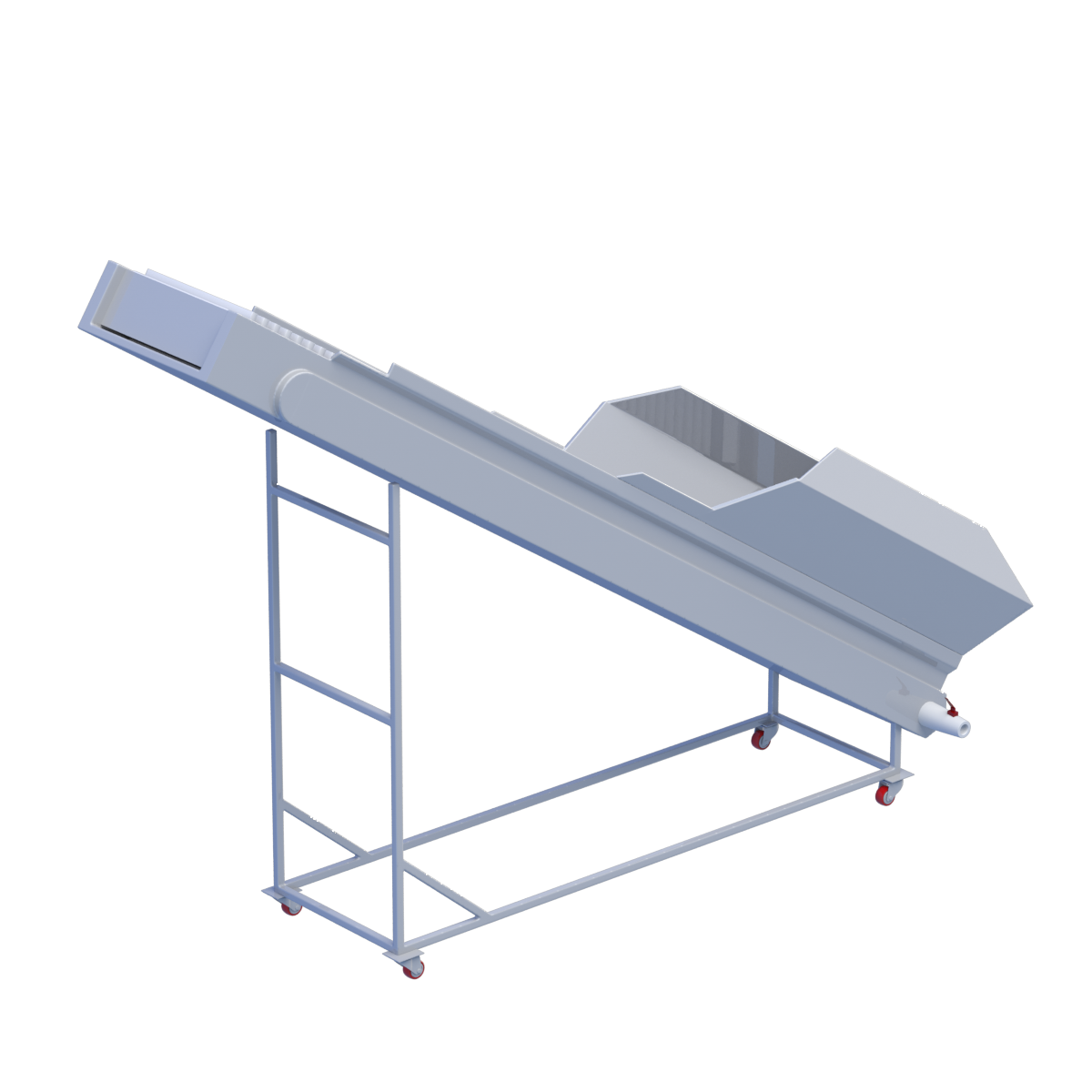

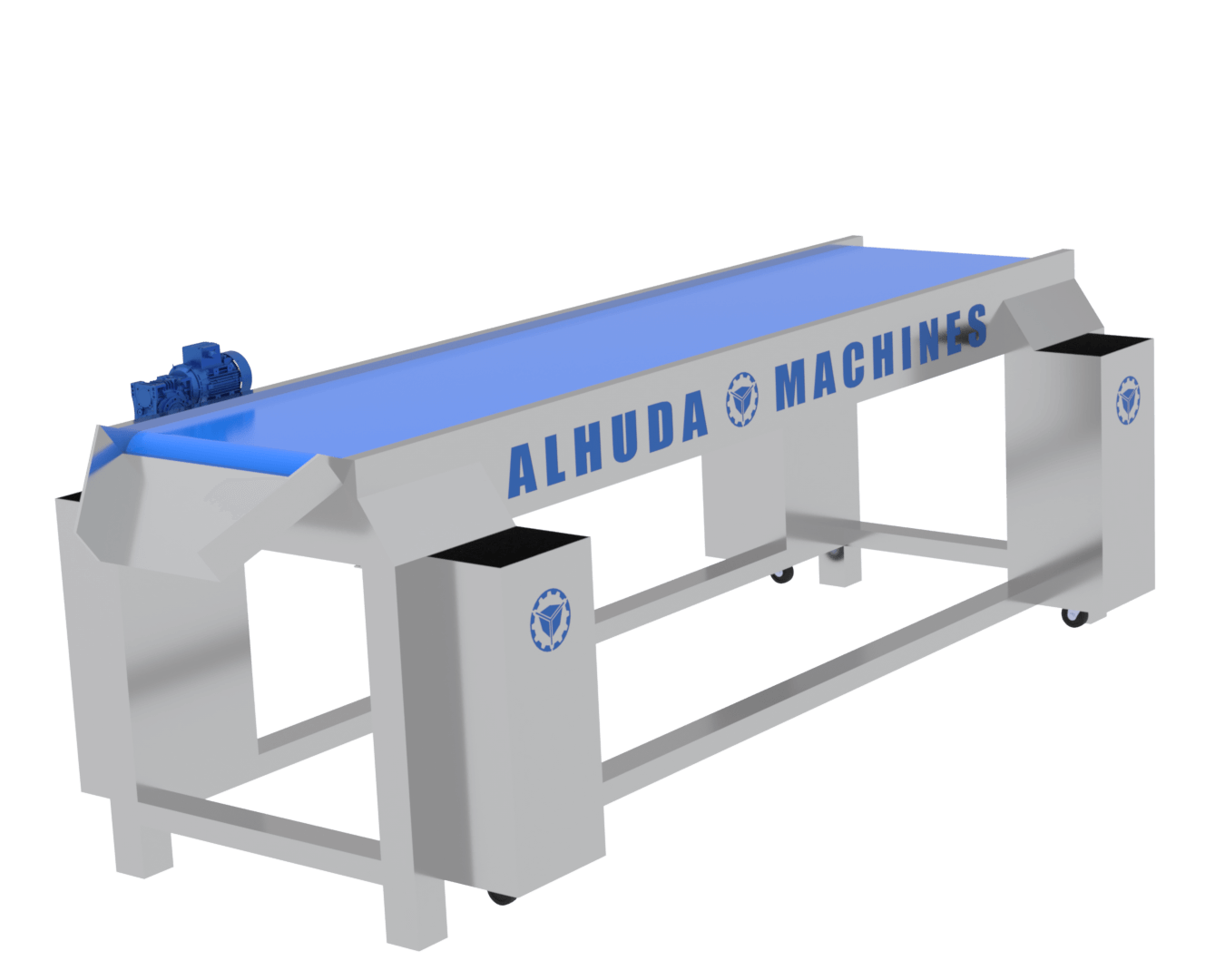

Conveyor belt with collection basin

Highly Efficient Potato Collection and Transport Process: The conveyor line with the collection basin is a key step in the potato production line. It ensures smooth and efficient collection and transport of potatoes to the washing line, achieving a smooth production process. Advanced Operation Mechanism:

1️⃣ Safe Potato Collection and Transport System

✔️ Potatoes are received inside a collection basin designed with a high capacity to accommodate large quantities.

✔️ Potatoes are transported along the conveyor belt in a balanced manner without causing any damage to the potatoes.

2️⃣ Durable Food-Grade Stainless Steel Construction

✔️ Designed entirely from food-grade 304 chrome stainless steel to ensure maximum hygiene and quality.

✔️ Resistant to corrosion and harsh industrial conditions for a long service life.

3️⃣ Energy-Saving Operating System

✔️ Relies on a powerful, highly efficient electric motor to ensure smooth potato transport.

✔️ Operates on 380/220V - 50Hz with low power consumption.

4️⃣ Solid structure to ensure sustainability and durability

✔️ Made of a 10 x 10 cm 304 stainless steel profile, providing strength and stability during operation.

✔️ The sink's sides are 3 mm thick for enhanced durability and sustainability.

5️⃣ Design for easy operation and maintenance

✔️ Equipped with stable and adjustable legs to ensure stability during operation.

✔️ Easy to disassemble and assemble for efficient maintenance and cleaning. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to ensure the highest standards of hygiene and quality.

✅ Electrical power: 3.75 kW | 380/220 V | 50 Hz.

✅ Dimensions: Length: 450 cm, Width: 150 cm, Height: 420 cm

✅ Part number: 001

✅ Model: ALEUDA-2024AS-M

✅ Country of manufacture: Turkey - High industrial quality according to European standards. Features of the conveyor line with a collection basin:

✔️ Durable, rust-resistant design for a long service life.

✔️ Smooth transport without damaging the potatoes.

✔️ Safe and energy-efficient operation with full control of the transport speed.

✔️ Easy maintenance and cleaning to ensure the highest levels of production efficiency.

💡 The perfect solution to ensure safe and smooth transport of potatoes within the production line!

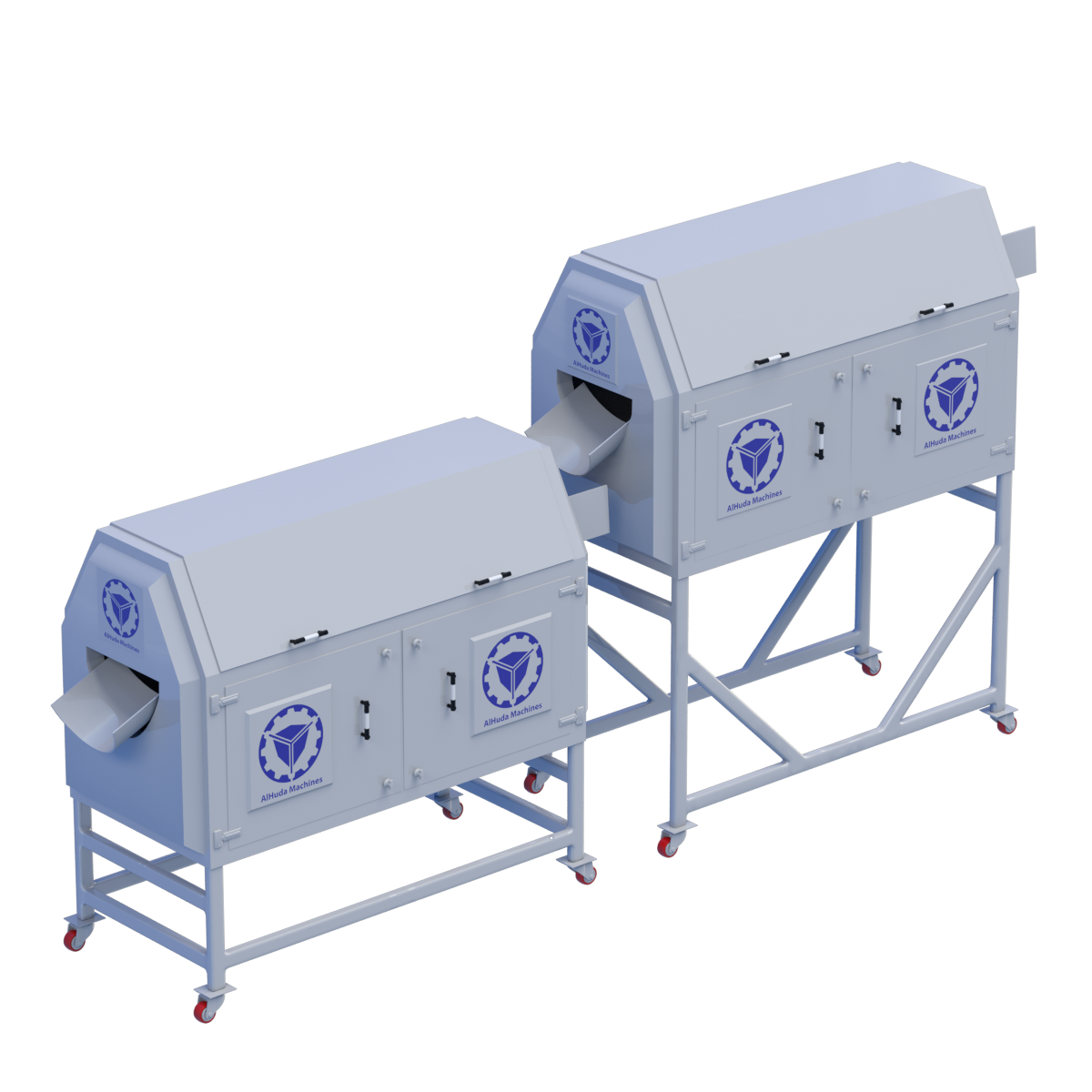

سPotato peeling machine 2

A key stage for efficient pre-processing potato peeling. The potato peeling machine effectively peels potatoes before they enter the other processing stages. It features a highly advanced peeling system that removes peels with minimal waste, helping to preserve the largest possible quantity of potatoes. The speed of the process can also be controlled using the latest speed variators to ensure maximum efficiency. The machine is designed for easy maintenance, including cleaning and washing, ensuring optimal operation.

⚙️ Advanced Operation Mechanism:

1️⃣ Efficient and Precise Peeling

✔️ Precise peeling removal with minimal waste to ensure maximum utilization of potato grains.

✔️ Advanced peeling system peels potatoes quickly and efficiently.

✔️ Speed control using modern speed variators to ensure optimal adjustment according to production needs.

2️⃣ Strong and Durable Structure

✔️ Made entirely of food-grade 304 stainless steel for corrosion resistance and hygiene.

✔️ Front and back wall thickness: 12 mm to ensure durability and strength.

✔️ Wall side thickness: 5 mm to support the frame and ensure machine stability.

✔️ 10 x 10 cm 304 stainless steel profile frame to support operation.

3️⃣ High performance with powerful motors

✔️ Electrical power: 9.75 kW – 380/220 V – 50 Hz.

✔️ Advanced electrical system ensures stable and continuous operation.

✔️ Powerful motors support high performance and reduce energy consumption.

4️⃣ Practical and easy-to-maintain ergonomic design

✔️ The design allows for easy maintenance and cleaning to ensure continuous operation at the highest efficiency.

✔️ The machine can be easily cleaned to prevent impurities from accumulating and maintain its efficiency.

✔️ Speed control is possible according to production needs to ensure optimal results.

📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel to ensure hygiene and quality.

✅ Dimensions:

✔️ Length: 600 cm

✔️ Width: 130 cm

✔️ Height: 340 cm

✅ Machine Number: 002

✅ Model: ALEUDA-2024AS-M

✅ Country of Origin: Turkey

✔️ Efficient peeling with minimal waste while preserving the maximum amount of potatoes.

✔️ Precise speed control using modern speed variators.

✔️ High-quality 304 food-grade stainless steel construction materials to ensure durability and hygiene.

✔️ Powerful motors to ensure stable operation and high efficiency.

✔️ Practical and easy-to-maintain design to extend the machine's lifespan.

💡 The perfect solution for peeling potatoes efficiently and with high quality before entering the processing stages!

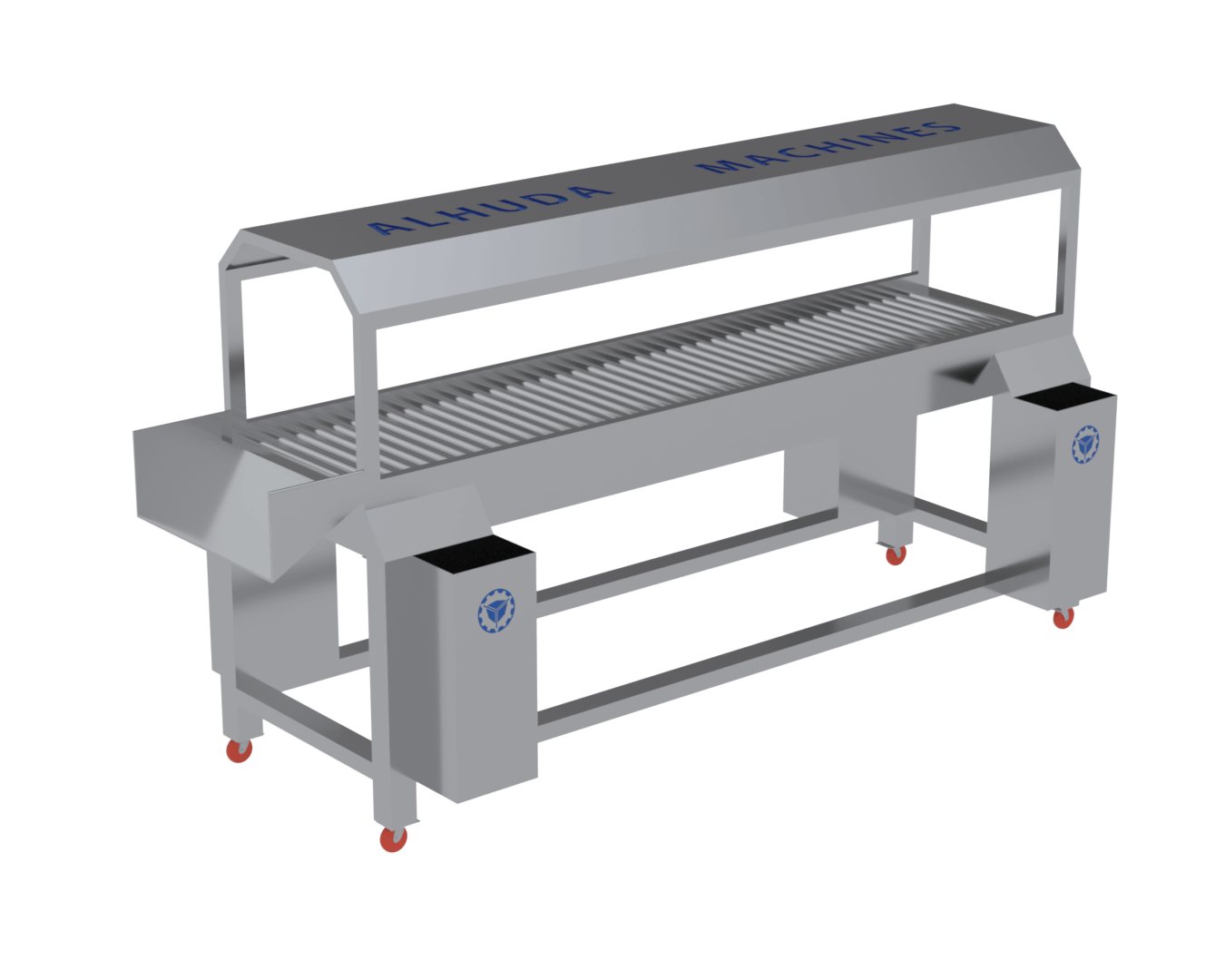

Conveyor belt for checking potatoes before they enter the cutter

Optical sorting selects high-quality potatoes accurately and efficiently removes damaged ones.

🥔 Optical and tactile sorting of potatoes

The rotary potato sorter is a crucial step in potato processing before cooking or frying. It rotates the potatoes and inspects them, automatically detecting and separating any unsuitable potatoes into a designated chute.

⚙️ Smart operating mechanism:

1️⃣ Precise potato rotation system

The machine rotates the potatoes evenly, allowing for the detection of external defects thanks to the continuous and controlled movement.

2️⃣ Automatic sorting chutes for damaged potatoes

Equipped with a sorting mechanism that automatically separates unsuitable potatoes and collects them in a dedicated container below the conveyor belt.

3️⃣ 304 stainless steel conveyor belt

A hygienic and durable conveyor belt, resistant to rust and designed for easy cleaning, making it perfectly suitable for the food industry.

4️⃣ Bottom collection bin for rejected potatoes

The damaged potatoes are collected in a separate bottom bin, maintaining a clean production line and ensuring fast processing.

5️⃣ Robust and durable engineering design

The machine features a balanced and professional stainless steel frame, designed to withstand continuous operation in production lines.

🛡️ Food-grade industrial design quality:

🔸 Manufactured in Turkey to European standards

🔸 Entire body made of food-grade 304 stainless steel – rust-resistant and safe for food processing

🔸 Easy to disassemble, maintain, and clean

🔸 Efficiently integrates into professional potato processing lines

📐 Technical Specifications:

Item Details

✅ Machine Number 003

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 160 cm

🔍 Features of the Rotary Potato Sorter:

✔️ Precise and automatic sorting of damaged potatoes

✔️ Hygienic and easy-to-clean conveyor belt

✔️ Dedicated bin for collecting rejected potatoes

✔️ Professional and durable engineering design

✔️ Ideal for large and medium-sized production lines

✔️ Reduces waste and improves processing quality

🎯 Who is this machine for?

If you are looking to improve the quality of your potatoes before frying or packaging, and save time and costs associated with manual sorting, this machine is the perfect solution to ensure quality and efficiency.

🔧 Start your production line with a smart choice... and let automated sorting elevate your product.

Conveyor line

🌊 Precise lifting and effective washing of potatoes before cutting

🥔 Smooth and continuous potato conveying

The integrated conveyor belt with a water tank is a key component in potato processing lines. It lifts the potatoes smoothly and consistently from the washing tank to the cutting machine, ensuring a continuous and uniform flow of product.

⚙️ Smart operating mechanism:

1️⃣ Reinforced 304 stainless steel conveyor belt

The conveyor belt is designed to handle food products gently and smoothly, ensuring that the potatoes are lifted without any damage or clumping.

2️⃣ Integrated water tank for initial washing

The integrated washing tank, made entirely of 304 stainless steel, is used to remove initial dirt from the potatoes before processing.

3️⃣ Controlled flow to the cutting machine

The machine ensures a continuous and consistent flow of potatoes to the cutting stage, improving efficiency and preventing unexpected downtime.

4️⃣ Powerful motor with precise electronic control

Equipped with a professional 2.25 kW motor operating at industrial voltage (380/220VAC) to ensure stable and continuous operation.

5️⃣ Hygienic design and easy maintenance

All parts are designed to be rust-resistant and easy to disassemble and maintain, extending the machine's lifespan and minimizing downtime.

🛡️ Food-Grade Industrial Design Quality:

🔸 Manufactured in Turkey to European standards

🔸 Made entirely of food-grade 304 stainless steel – rust-resistant and safe for food processing

🔸 Professional design compliant with food safety and quality standards

🔸 Ready for continuous operation in potato processing lines

📐 Technical Specifications:

Item Details

✅ Machine Number 004

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 280 cm

✅ Width 120 cm

✅ Height 180 cm

🔍 Features of the Conveyor Belt with Washing Tank:

✔️ Smooth and consistent transport of potatoes to the cutting machine

✔️ Integrated washing tank for efficient initial cleaning

✔️ Food-grade, rust-resistant stainless steel

✔️ Reduces waste and improves processing efficiency

✔️ Easy-to-clean design suitable for continuous operation

✔️ Ideal for potato and potato chip production lines

🎯 Who is this for?

For anyone looking to increase efficiency in potato processing lines and achieve a smooth, uninterrupted product flow. This machine guarantees a strong start for your professional production line.

🔧 Smooth and efficient transport... is the foundation of high-quality finished products.

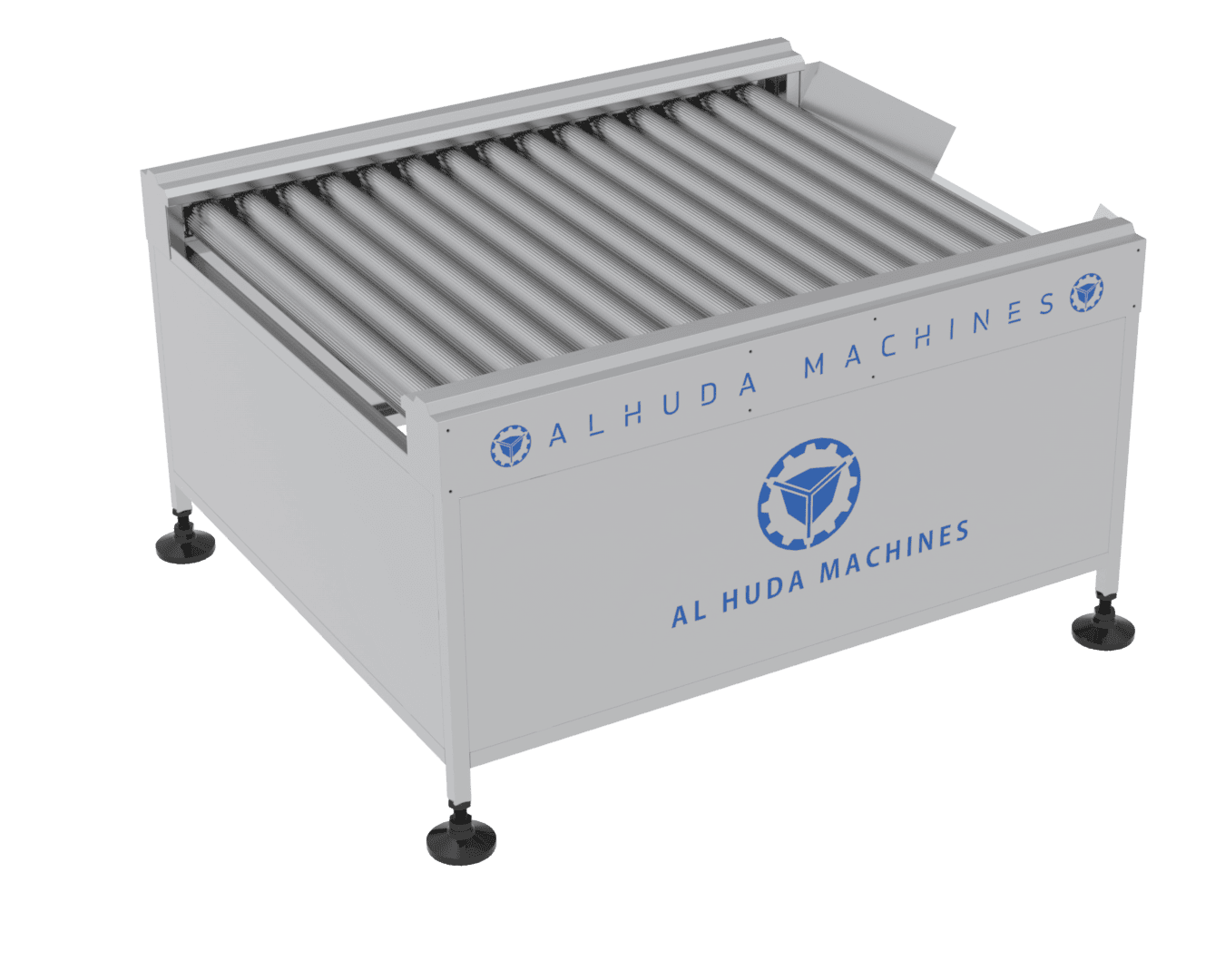

Sorting vibrator

Intelligent vibration... for precise feeding and clump prevention

🥔 Gentle sorting for smooth potato flow

The vibrating conveyor is a key component in potato processing lines. It gently sorts the potatoes, ensuring they flow smoothly along a designated path and preventing clumping or random movement, thus facilitating consistent feeding to downstream equipment such as cutters or washers.

⚙️ Smart operating mechanism:

1️⃣ Four-stage, high-frequency vibration

The conveyor is designed with four progressive vibration stages. The potatoes start moving gently, and the vibration intensity increases gradually, allowing for optimal separation and distribution.

2️⃣ Dedicated path for consistent feeding

The conveyor guides the potatoes along a single path, preventing random feeding to downstream machines and improving overall efficiency.

3️⃣ Clumping and accumulation prevention

Thanks to the dynamic vibration system, the potatoes are prevented from piling up, ensuring they move individually and evenly.

4️⃣ Food-grade 304 stainless steel design

All parts that come into contact with the product are made of food-grade 304 stainless steel, guaranteeing the highest standards of hygiene and food safety.

5️⃣ Powerful motor for continuous operation

Equipped with a 4.5 kW motor (380/220 VAC – 50 Hz), it allows for long-term, reliable operation in professional production lines.

🛡️ Food-grade industrial design quality:

🔸 Manufactured in Turkey to European standards

🔸 Made entirely of 304 stainless steel – food-safe and rust-resistant

🔸 Easy to disassemble, maintain, and clean

🔸 Designed to withstand heavy-duty industrial use

📐 Technical Specifications:

Item Details

✅ Machine Number 005

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 4.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 230 cm

✅ Width 80 cm

✅ Height 170 cm

🔍 Features of the Sorting Vibrator:

✔️ Four-stage, gradual vibration for efficient sorting

✔️ Prevents potato clumping and ensures even feeding

✔️ Guarantees consistent feed rate to downstream machines

✔️ Made of high-quality, food-grade materials

✔️ Stable operation, suitable for demanding environments

✔️ Ideal for potato chip and French fry production lines

🎯 Who is this machine for?

If you are looking for a consistent flow of potatoes and a smooth, reliable feed to your cutting or washing machines, this sorting vibrator is the perfect solution for efficient and professional production.

🔧 Controlled vibration... the smart start to any precise processing operation.

Slicer server

Intelligent Feeding System... For Precise and Safe Cutting

🥔 Regulating the Flow of Potatoes to the Slicer

The potato feeder is one of the most important components in a potato processing line. It regulates the flow of potatoes to the slicer, preventing any irregular feeding that could damage the blades or cause machine malfunctions. Consistent feeding is key to the smooth operation of the entire production line.

⚙️ Smart Operating Mechanism:

1️⃣ Consistent Potato Feeding

The system arranges and feeds the potatoes to the slicer in a continuous and uniform flow, protecting the system from overload or bottlenecks.

2️⃣ Protection for the Slicer

Thanks to the intelligent feeding system, the risk of irregular feeding that could damage the slicer blades or cause a sudden production stoppage is minimized.

3️⃣ Optimizing the Entire Production Flow

It plays a vital role in streamlining the workflow throughout the entire production line, from sorting to packaging, maintaining a consistent production rhythm.

4️⃣ Hygienic and Safe Design

All parts of the feeder are made of food-grade 304 stainless steel, making it ideal for food processing environments.

5️⃣ Efficient Industrial Motor

Equipped with a 1.5 kW electric motor operating on 380/220VAC – 50Hz, it provides ample power for stable and quiet operation.

🛡️ Food-grade industrial design quality:

🔸 Made in Turkey to European standards

🔸 100% food-grade 304 stainless steel – rust-resistant and safe for food processing

🔸 Easy to disassemble, clean, and maintain

🔸 Works seamlessly with other parts of the production line

📐 Technical Specifications:

Item Details

✅ Machine Number 006

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Rating 1.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 150 cm

✅ Width 50 cm

✅ Height 170 cm

🔍 Features of the Potato Feeder:

✔️ Prevents irregular feeding and protects the cutting machine

✔️ Ensures consistent feeding of potato pieces

✔️ Enhances the stability of the production flow throughout the line

✔️ Hygienic and safe design for food processing

✔️ Stable operation with low energy consumption

✔️ Ideal for French fries and potato chip production lines

🎯 Who is this machine for?

For anyone seeking perfect cutting results and consistent product quality without downtime or malfunctions, the potato feeder is a key element for a successful production line.

🔧 Controlled feeding... is the guarantee for efficient operation from start to finish.

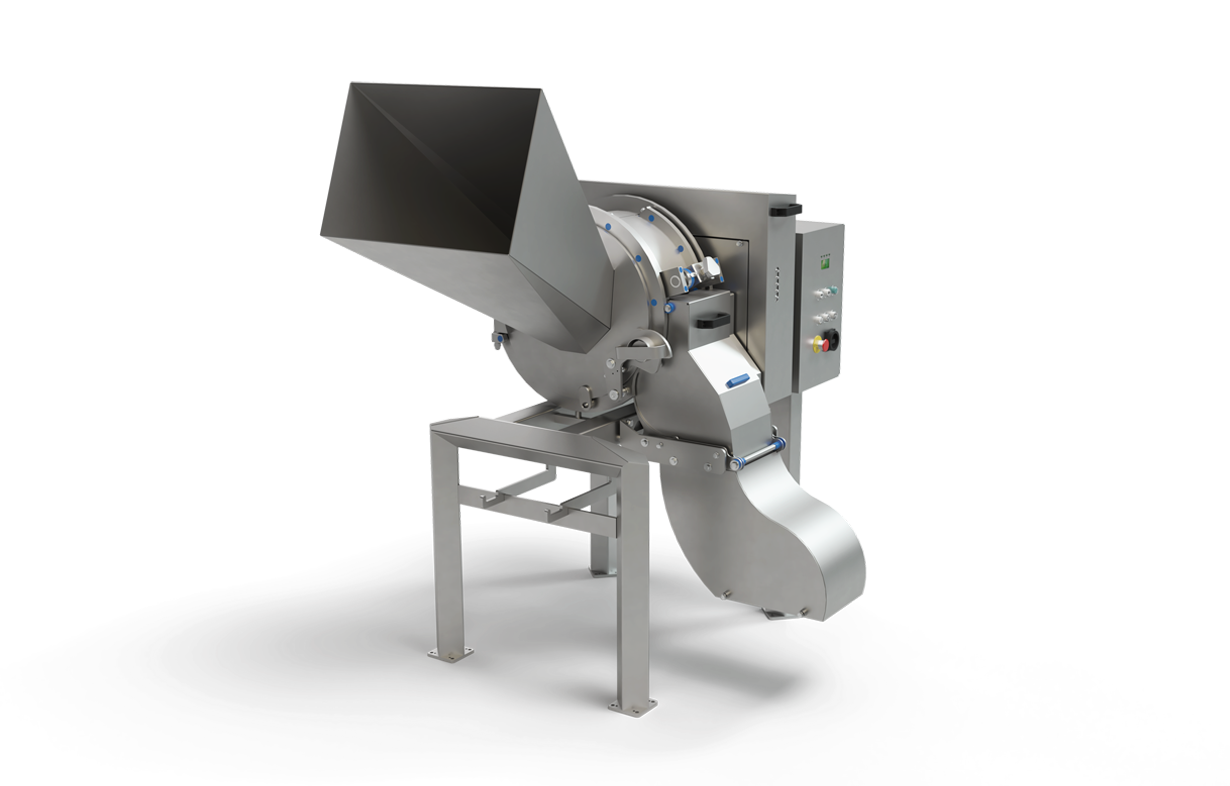

FAM potato cutting machine

🔪 Belgian precision... Perfect cutting with no waste

🥔 Professional potato cutting machine for precise sizes

This potato cutter from the Belgian company FAM is one of the most advanced cutting machines available. It cuts potatoes without damaging their surface, minimizing waste. Designed to meet the demands of professional production lines, it offers superior quality, efficiency, and speed.

⚙️ Smart operating mechanism:

1️⃣ High-quality Belgian blades

The cutter provides precise and uniform cutting of potato strips in various sizes, as needed, while maintaining a smooth, undamaged surface.

2️⃣ High operational efficiency

Easy to operate and maintain, reducing downtime and increasing productivity, saving time and money.

3️⃣ Minimal potato waste

Thanks to the precise cutting system, the potato is utilized to its fullest extent, with no waste or breakage.

4️⃣ Hygienic and safe design

Made of food-grade 304 stainless steel, making it ideal for food processing environments.

5️⃣ Industrial-grade electric motor

Equipped with a 1.5 kW motor operating at 380/220VAC – 50Hz, ensuring stable and efficient performance in long production lines.

🛡️ Food-grade industrial design quality:

🔸 Made in Belgium – by FAM, a leading company in cutting technology

🔸 Designed for continuous industrial use

🔸 Made entirely of food-grade 304 stainless steel

🔸 Easy maintenance and quick cleaning

🔸 Reliable performance in professional production lines

📐 Technical Specifications:

Item Details

✅ Machine Number 007

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Belgium 🇧🇪 – FAM

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 1.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 120 cm

✅ Width 100 cm

✅ Height 150 cm

🔍 Features of the FAM Potato Cutter:

✔️ Precise cutting of potato strips in various sizes

✔️ Does not damage the potato surface

✔️ Significantly reduces waste

✔️ 100% hygienic and safe design

✔️ Easy operation and low maintenance

✔️ Ideal for French fries and potato chip production lines

🎯 Who is this machine for?

If you are looking for the highest quality potato cutting without waste, and need a reliable machine capable of operating in professional production lines, then the FAM potato cutter is the perfect choice.

🔧 Precision cutting... means a professional-quality final product.

Built-in conveyor belt with water basin

🚿Double washing... Precise cutting and intelligent conveying for perfect sorting

🥔 Cutting, washing, and cleaning... all in one integrated process

This smart, multi-functional line combines cutting in a water tank, initial washing with a whirlpool system, and secondary washing with water sprays, followed by automatic conveying of the potato strips to the sorting machine. This system is designed to reduce starch content, improve product cleanliness, and ensure that the potato strips are conveyed without breakage or clumping.

⚙️ Smart working mechanism:

1️⃣ Cutting in a built-in water tank

The potatoes are cut directly inside the water tank, which helps absorb impact and protects the strips from breaking or sticking together.

2️⃣ Whirlpool system for effective initial cleaning

The water circulates in a whirlpool motion, gently agitating the potato strips after cutting, helping to remove impurities and excess starch.

3️⃣ Integrated conveyor belt for automatic conveying

After cutting and washing, the strips are conveyed by a built-in belt, ensuring smooth transfer to the next stage.

4️⃣ Secondary washing with water sprays

During the conveying process, the strips pass under powerful water sprays that remove any remaining starch and further improve product quality before sorting.

5️⃣ Ideal preparation for the sorting stage

The potato strips are conveyed to the sorting machine, ready for separation into the desired size and removal of any unwanted pieces. 🛡️ Food-grade industrial design quality:

🔸 Manufactured in Turkey to European quality standards

🔸 Entire body made of food-grade 304 stainless steel, rust-resistant

🔸 Compact design combines washing, cutting, and conveying functions

🔸 Easy maintenance and optimal hygiene thanks to the open steel structure

📐 Technical Specifications:

Item Details

✅ Machine Number 008

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 280 cm

✅ Width 120 cm

✅ Height 180 cm

🔍 Features of the Integrated Water Tank System:

✔️ Direct cutting within the water tank to minimize breakage and damage

✔️ Efficient whirlpool system for removing impurities and starch

✔️ High-performance secondary water spray nozzles

✔️ Smooth, automated conveying without clogging or damage

✔️ Improved potato quality before sorting

✔️ Durable, easy-to-clean, and easy-to-maintain structure

🎯 Who is this system for?

If you are looking to combine several processes into one integrated unit to save space, time, and improve potato quality before sorting, this system is the ideal solution.

🔧 Professional washing... Smart conveying... Perfect preparation for sorting.

Automatic conveyor belt for sorting potato fingers

🌀The final touch... your product quality starts here

🥔 Professional potato finger sorting – no crumbs, no impurities

This system is meticulously designed to separate unwanted small pieces (crumbs) from the potato fingers after cutting, ensuring consistent quality in the final product. It utilizes rotating rollers made of food-grade polyamide, with adjustable speed to suit the desired sorting level.

⚙️ Smart operating mechanism:

1️⃣ High-quality food-grade polyamide rollers

The rollers are made of food-grade polyamide, allowing standard-sized potato fingers to pass through while smaller, unwanted pieces fall through the gaps.

2️⃣ Precise sorting of crumbs and broken pieces

The system effectively separates crumbs and broken pieces resulting from the cutting process, improving packaging quality and preventing their inclusion in the final product.

3️⃣ Electronic speed control (Inverter)

Equipped with an electronic speed control system, allowing you to adjust the conveyor speed according to the required sorting accuracy and quality.

4️⃣ Hygienic and safe design

The frame is made entirely of food-grade 304 stainless steel, rust-resistant and easy to clean, making it ideal for food processing environments.

5️⃣ Seamless integration into the production line

This system is installed after the potato finger washing stage and before packaging or frying, ensuring a flawless final product.

🛡️ Food-grade industrial design quality:

🔸 Made in Turkey to European standards

🔸 Food-safe plastic and metal components

🔸 Easy to clean and maintain

🔸 Ideal for high-capacity, continuous industrial production lines

📐 Technical Specifications:

Item Details

✅ Machine ID 009

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material 304 Stainless Steel + Food-grade Polyamide

✅ Power Rating 1.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 150 cm

✅ Width 50 cm

✅ Height 170 cm

🔍 Features of the Sorting Conveyor Belt:

✔️ Precise sorting of small pieces and granules

✔️ Safe and efficient food-grade polyamide rollers

✔️ Fully adjustable speed control

✔️ Directly improves packaging or frying quality

✔️ Hygienic design, easy to maintain and clean

✔️ Ideal for industrial potato processing lines

🎯 Who is this machine for?

For those who want to guarantee a final product free of broken pieces and unwanted debris, while maintaining a consistent shape for potato products, this conveyor belt is an essential part of the production line.

🔧 Attention to detail... makes all the difference in product quality.

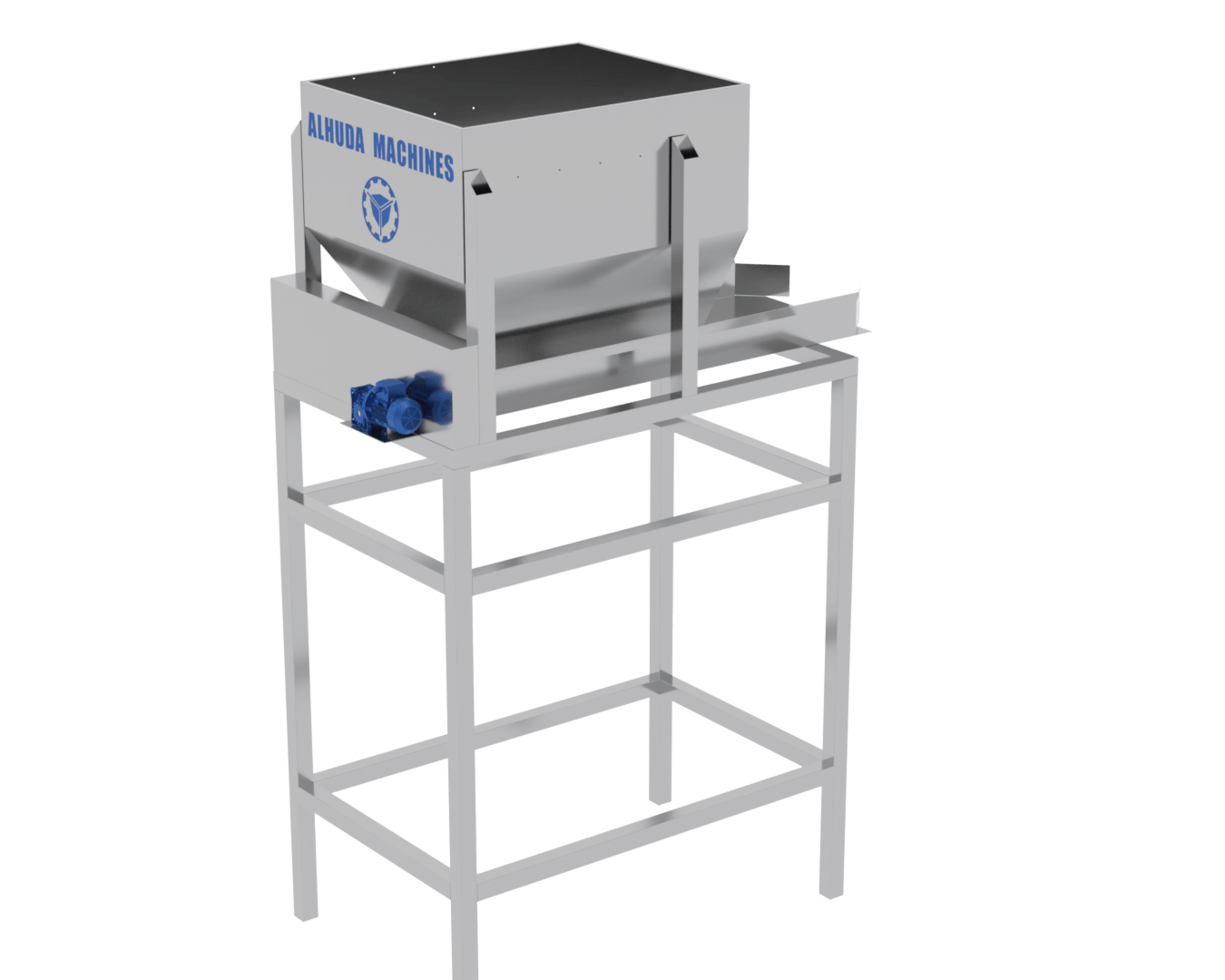

A machine for removing starch, adjusting sugar, and bleaching potato fingers

💧 Potato Blanching Machine: Lightens color... Removes starch... Ensures perfect pre-fried quality

🍟 An essential step in producing high-quality pre-fried potatoes

The potato blanching machine (or starch extractor) processes potato strips after sorting, removing excess sugars and starch, and lightening the color before frying. It utilizes a deep water washing system with a whirlpool effect, combined with high-pressure water and air, making it a crucial tool for improving the appearance, taste, and overall quality of the potatoes.

⚙️ Smart Operating Mechanism:

1️⃣ High-pressure water washing with a whirlpool effect

The potato strips are gently agitated in a pressurized water tank with a swirling motion (whirlpool effect), effectively removing internal starch and sugars without damaging the potato structure.

2️⃣ Rotating cylindrical tank for precise agitation

The potatoes are moved within a rotating cylindrical tank, ensuring thorough washing of all sides and preventing clumping or sticking together.

3️⃣ Final rinse with pressurized water

Before exiting the machine, the potatoes pass through high-pressure water nozzles, removing any remaining surface starch or sugars.

4️⃣ Adjustable processing time

The time the potatoes spend in the tank can be adjusted according to the potato type and desired processing level, ensuring effective blanching and sugar removal.

5️⃣ Intelligent conveyor belt with electronic control

Equipped with a motor whose speed can be adjusted via an inverter, allowing precise control of the processing time for each batch.

6️⃣ Two integrated pumps – air and water

🔹 High-pressure air pump: for generating the whirlpool effect

🔹 High-pressure water pump: for adjustable spray nozzles with controllable direction and pressure

7️⃣ Hydraulic system for raising and lowering the moving part

The machine is equipped with four hydraulic cylinders to ensure safe and smooth raising and lowering of the moving part during cleaning or maintenance.

🛡️ Food-grade industrial design quality:

🔸 Manufactured in Turkey to European standards

🔸 Entire frame made of food-grade 304 stainless steel, rust-resistant

🔸 Designed for continuous operation in professional production lines

🔸 Safe, easy to maintain and clean

📐 Technical Specifications:

Item Details

✅ Machine Number 010

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 5.25 kW

✅ Voltage 380/220VAC – 50Hz

✅ Length 600 cm

✅ Width 140 cm

✅ Height 200 cm

🔍 Features of the Blanching/Starch Removal Machine:

✔️ Effectively removes starch and sugars from potato strips

✔️ Improves the color of potatoes before frying (lightens and whitens)

✔️ Integrated whirlpool system for gentle agitation and washing

✔️ Final rinse with adjustable water pressure

✔️ Adjustable processing time and conveyor speed

✔️ Hydraulic lifting system for safe maintenance and cleaning

✔️ Ideal for semi-fried or frozen potato production lines

🎯 Who is this machine for? If you want to produce perfectly cooked, golden-brown potato products with a clean flavor, free from bitterness or dark spots caused by excess starch, a blanching machine is essential for ensuring consistent quality.

🔧 Smart processing... the key to excellence in every potato product.

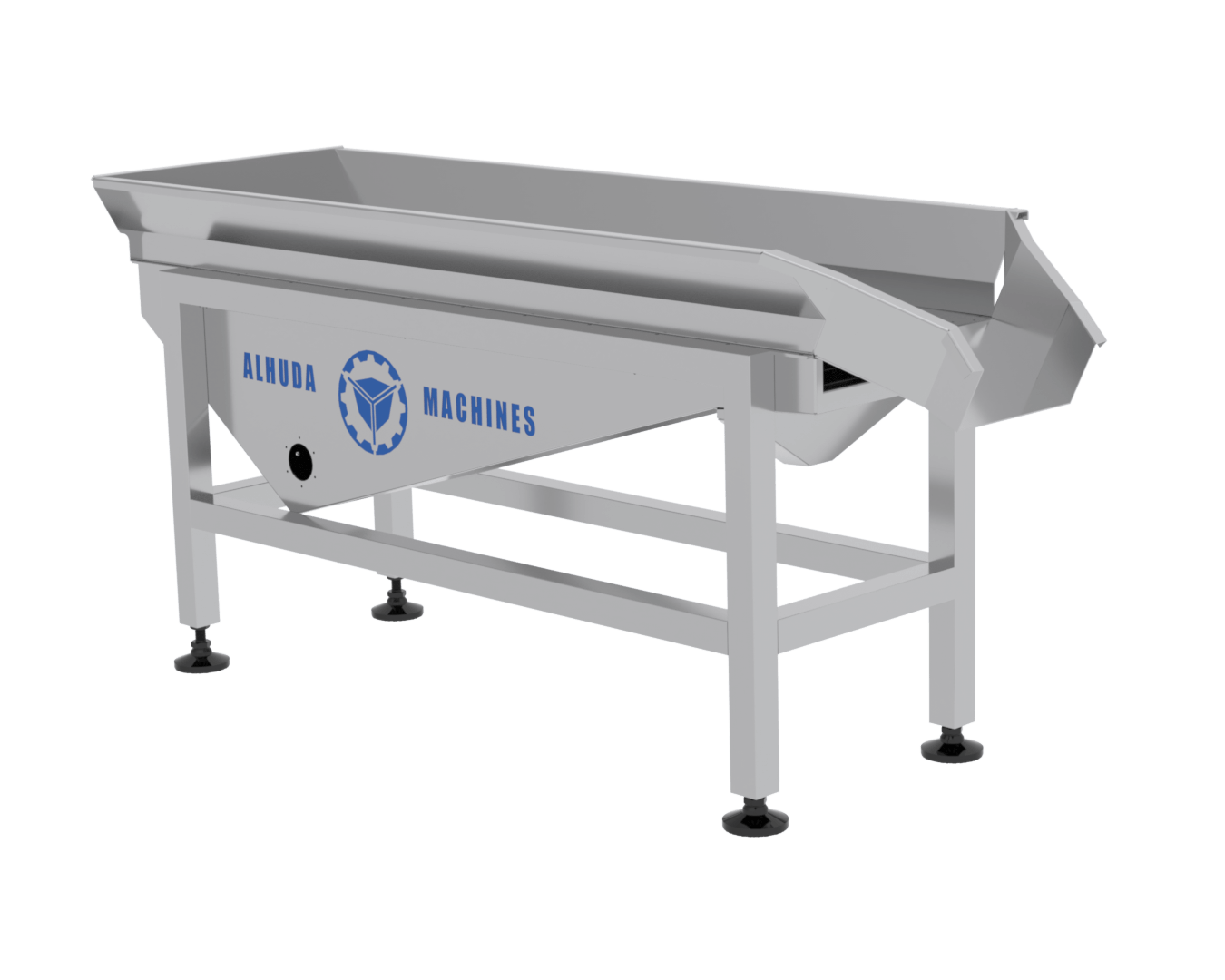

Water separator and distributor shaker

🔃 Vibrating Separator: Ideal for preparing potato strips for frying or packaging... No more clumping!

🥔 Separates and partially dries potato strips after washing or blanching

This machine is a vital step in the semi-processed potato production line. It uses a carefully designed mechanical vibration to separate and partially dry the potato strips, ensuring they flow smoothly to the frying or freezing stage without clumps that could affect the final product quality.

⚙️ Smart Operating Mechanism:

1️⃣ Separates Clustered Strips

Thanks to its high-frequency vibration, this machine separates the potato strips after processing or blanching, ensuring they enter the frying or packaging process individually and uniformly.

2️⃣ Effective Initial Drying

The vibration also helps to dry the surface of the strips, removing excess moisture from washing or blanching, thus minimizing the impact of moisture on the frying or freezing stages.

3️⃣ Durable and Easy-to-Clean Design

The entire frame of the vibrator is made of food-grade 304 stainless steel, making it perfectly suitable for food processing environments.

4️⃣ High-Performance Industrial Motor

Equipped with a 2.25 kW motor, it operates efficiently on industrial power: 380/220VAC – 50Hz.

5️⃣ Continuous Operation with Minimal Vibration and Noise

Designed with a stable base and vibration dampers to minimize noise and ensure smooth, safe operation. 🛡️ Food-grade industrial design quality:

🔸 Made in Turkey to European standards

🔸 Designed for continuous operation in potato processing lines

🔸 All parts that come into contact with potatoes are made of 304 stainless steel

🔸 Easy to maintain, disassemble, and clean

📐 Technical Specifications:

Item Details

✅ Machine Number 011

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 250 cm

✅ Width 100 cm

✅ Height 200 cm

🔍 Features of the Potato Separator/Shaker:

✔️ Effectively separates stuck potato pieces after washing or blanching

✔️ Reduces surface moisture before frying or packaging

✔️ Improves potato distribution and prevents clumping in the fryer

✔️ Hygienic and durable design for industrial use

✔️ Stable operation with minimal noise

✔️ Ideal for semi-processed or frozen potato production lines

🎯 Who is this machine for?

If you want to improve frying quality, prevent potato pieces from sticking together, or reduce moisture content before freezing, this potato separator/shaker is an essential piece of equipment for your production line.

🔧 Precise separation and gentle shaking... ensuring each potato piece is in its proper place.

Hot air-drying tunnel

🌬️ Air Dryer for French Fries - Moisture Removal

🍟 Professional drying before frying for a golden-crisp result

This machine uses a powerful stream of hot air to dry partially fried French fries, removing any remaining moisture. This process enhances crispiness, reduces oil absorption, and prevents clumping during frying or packaging.

⚙️ Smart Operating Mechanism:

1️⃣ Hot Air Drying System

The French fries are conveyed on a special belt through a chamber where a concentrated stream of hot air dries them quickly and efficiently.

2️⃣ Six Closed-Loop Fans

Six high-capacity fans circulate the hot air within the chamber in a closed loop, maximizing thermal efficiency and reducing energy consumption.

3️⃣ Industrial Electric Heaters

Equipped with powerful electric heaters that preheat the air before it enters the drying chamber, ensuring a consistent temperature.

4️⃣ Uniform Drying Without Clumping

The airflow is carefully designed to prevent the fries from clumping or sticking together, ensuring even drying before frying.

5️⃣ Improved Fry Oil Lifespan

By reducing moisture, the risk of steam or bubbling in the fryer is minimized, keeping the oil cleaner and extending its lifespan.

6️⃣ Full Electronic Control

Adjust the conveyor speed, air temperature, and airflow distribution to suit the type of potato and desired moisture level.

🛡️ Food-grade industrial design quality:

🔸 Manufactured in Turkey to European standards

🔸 Entire structure made of food-grade 304 stainless steel, resistant to rust

🔸 Safe and durable design suitable for continuous operation

🔸 Easy access for maintenance and cleaning

📐 Technical Specifications:

Item Details

✅ Machine Number 012

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 9.75 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 160 cm

🔍 Features of the Potato Strips Dryer:

✔️ Fast and efficient drying of internal moisture

✔️ Improves crispness and overall frying quality

✔️ Hot air system with 6 closed-loop fans

✔️ Powerful, thermally efficient electric heaters

✔️ Reduces oil absorption and prevents bubbling

✔️ Hygienic design, easy to clean and maintain

🎯 Who is this machine for?

For those involved in the production of frozen potato products who aim to improve frying quality, reduce clumping, and ensure optimal crispness, this hot air dryer is an essential piece of equipment for your production line.

🔧 Controlled drying... for irresistible crispness.

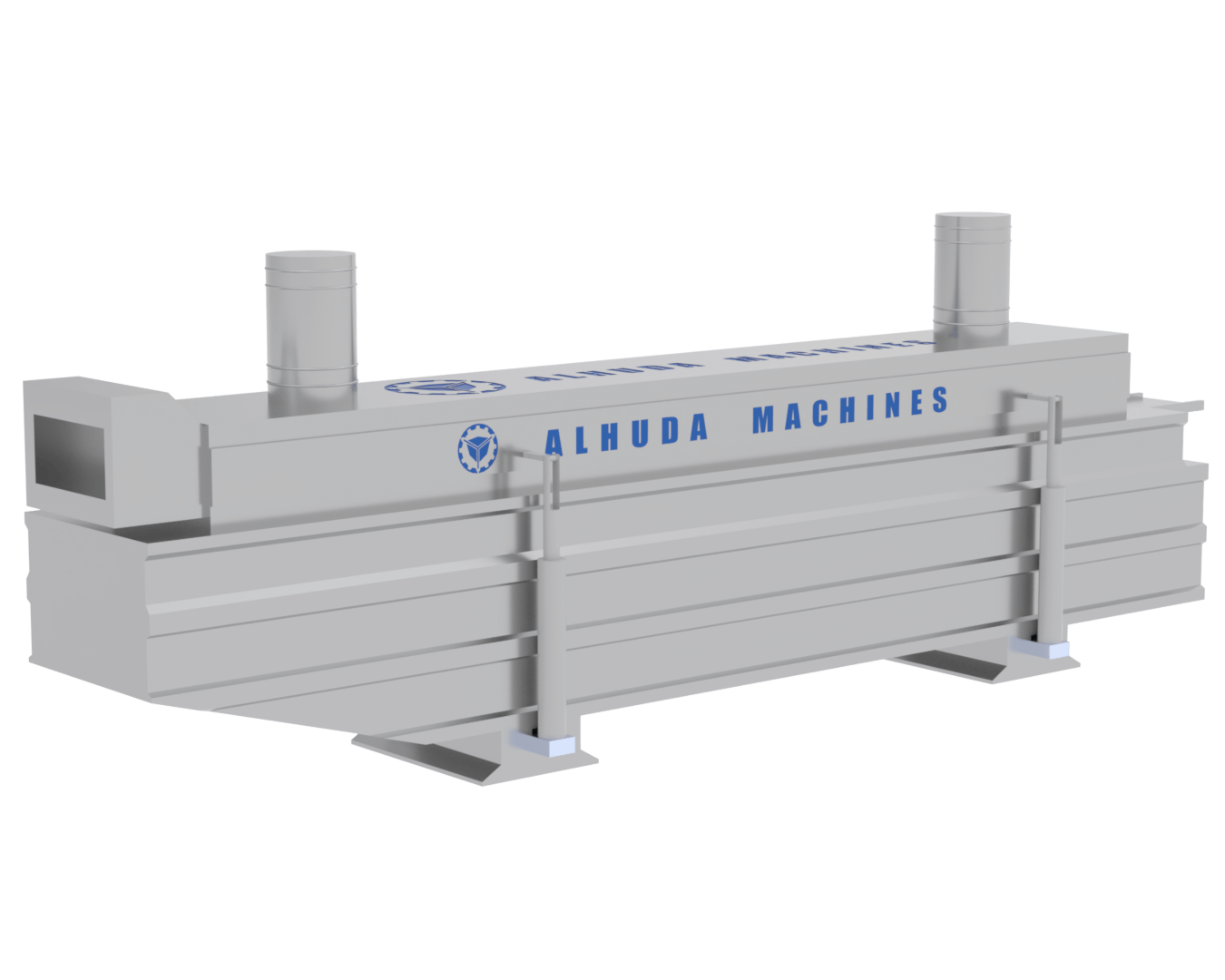

Continuous semi-fried potato fryer

🔥Precise temperature control... Pure oil... Perfect crispiness

🥔 The heart of the production line... Where effort transforms into irresistible quality

The continuous fryer is a crucial component of the frozen potato production line. It ensures uniform and precise frying of potato strips at a controlled and stable temperature, while maintaining the oil quality for as long as possible thanks to its continuous oil circulation and filtration system.

⚙️ Smart operating mechanism:

1️⃣ External heating system via a boiler:

The oil inside the fryer is heated by an external boiler-operated heat exchanger, providing better temperature control and preventing oil from burning in the tank.

2️⃣ Continuous agitation of the potatoes in the oil:

The fryer features an internal agitation system that continuously stirs the potatoes in the oil, ensuring even heat distribution and uniform cooking.

3️⃣ PID temperature control system:

Equipped with a PID electronic control system that maintains the oil temperature at an optimal level, regardless of operating conditions or changes in the fryer's load.

4️⃣ Safety system in case of power outage or malfunction:

In the event of a power outage or malfunction, the fryer automatically retracts the potatoes from the frying tank via an independent mechanical system, preventing the product from burning in the oil.

5️⃣ Fully hydraulic lifting system:

All moving parts of the fryer (covers, belts, dividers) can be raised or lowered safely and smoothly using six hydraulic cylinders powered by oil pressure.

6️⃣ Conveyor with Speed Control (Inverter):

The conveyor belt for moving potatoes into and out of the fryer is equipped with an industrial motor, adjustable via an inverter, allowing you to control the frying time based on the size and shape of the product.

7️⃣ Three-Stage Oil Filtration System:

Features a closed-loop system that continuously filters the oil during frying, removing impurities and particles, thus maintaining oil cleanliness and cooking quality.

8️⃣ High-Flow Industrial Oil Pump:

Equipped with a powerful pump with a capacity of 100,000 liters/hour, ensuring rapid oil circulation through the filters and heat exchanger.

9️⃣ Full Thermal Insulation:

The fryer is completely encased in 12 cm thick thermal insulation, maintaining internal temperature and ensuring safety for operators.

10️⃣ Dual Oil Tanks (Double Jacket):

Clean oil tank: 800-liter capacity – maintains the required oil level.

Used oil tank: 800-liter capacity – collects and safely stores used oil from the fryer.

Both tanks are equipped with internal heaters to keep the oil warm and ready for use.

11️⃣ Multiple Cleaning and Maintenance Ports:

Features multiple ports for easy oil draining and cleaning of the tank, pipes, and filters.

12️⃣ Dedicated Oil Vapor Exhaust Ports:

The fryer is designed with two dedicated ports for oil vapor and steam exhaust, ensuring a safe working environment and minimizing vapor buildup in the production area.

🛡️ Food-Grade Industrial Design Quality:

🔸 High-quality Turkish manufacturing, adhering to European standards

🔸 Entire structure made of food-grade 304 stainless steel, rust-resistant

🔸 Design prioritizes continuous operation, ease of cleaning, and maintenance

🔸 All components are designed to withstand high temperatures and prolonged operation

📐 Technical Specifications:

Item Details

✅ Machine Number 013

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 20.25 kW

✅ Voltage 380/220VAC – 50Hz

✅ Length 800 cm

✅ Width 150 cm

✅ Height 200 cm

✅ Tank Capacity 2 x 800 liters

✅ Insulation Thickness 12 cm (thermal fiber)

✅ Pump Capacity 100,000 liters/hour

🔍 Features of the Semi-Fried Potato Frying Machine:

✔️ Precise temperature control – PID system

✔️ Safe and efficient external heating via a boiler

✔️ Continuous agitation in the frying tank for optimal distribution

✔️ Smart emergency system to withdraw product during power outages

✔️ Continuous oil filtration – 3 stages

✔️ Dual oil tanks with internal heaters

✔️ Full insulation for operator safety and energy efficiency

✔️ Easy maintenance, operation, and cleaning

🎯 Who is this fryer for?

For any food processing plant seeking to produce high-quality semi-fried potatoes, while reducing oil consumption, improving texture, and achieving consistent results throughout the day.

🔧 The frying process... that's what makes the difference between an ordinary product and an unforgettable one.

Oil drying vibrator

🌀 Oil Removal Shaker: Goodbye Excess Oil... Hello High Quality!

🍟 Precise Drying After Frying for Cleaner, Crispier Potatoes

The oil removal shaker is a crucial post-frying stage in frozen potato production lines. It removes excess oil from the potato chips, improving flavor, extending shelf life, and preventing sticking or crumbling during packaging.

⚙️ Smart Operating Mechanism:

1️⃣ High-Frequency Vibrating System for Efficient Drying:

The shaker utilizes a precise vibrating system that quickly and efficiently removes excess oil from the fried potato chips without affecting their shape or texture.

2️⃣ 4-Stage Gradual Conveyor Belt:

The oil is filtered in four sequential stages through a gradual, calculated movement, allowing for maximum drying without damaging or breaking the chips.

3️⃣ Prevents Sticking and Clumping:

The continuous vibration prevents the fried potatoes from sticking together, improving flow on the conveyor belt and facilitating easier packaging.

4️⃣ Hygienic, Oil-Resistant Design:

The shaker is made entirely of food-grade 304 stainless steel, resistant to rust and hot oil, ensuring product safety and easy cleaning.

5️⃣ Full Industrial Control:

Equipped with a high-performance 4.5 kW industrial motor, allowing for adjustable speed and vibration intensity according to the type of potato and production stage.

🛡️ Food-grade industrial design quality:

🔸 Professional Turkish design, meeting European standards

🔸 Entire frame made of food-grade 304 stainless steel

🔸 Designed for continuous operation in high-performance production lines

🔸 Easy to disassemble, clean, and maintain

📐 Technical Specifications:

Item Details

✅ Machine Number 014

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 4.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 300 cm

✅ Width 100 cm

✅ Height 140 cm

🔍 Features of the Oil Removal Shaker:

✔️ Effectively reduces excess oil from the chips

✔️ Prevents chips from sticking together during transport or packaging

✔️ Minimizes breakage or chipping

✔️ Full control over vibration intensity and speed

✔️ Oil-resistant and easy-to-clean design

✔️ Improves the overall appearance of the potatoes and extends shelf life

🎯 Who is this machine for?

If you aim to produce high-quality, pre-fried potatoes with no excess oil and an attractive appearance, an oil removal shaker is an essential piece of equipment for your production line.

🔧 Precise drying after frying... equals an irresistible final product.

Conveyor belt route for potato inspection

👁️🗨️ The quality control process starts with the eye... and ends with customer satisfaction

🍟 A crucial step to ensure the purity and professionalism of the final product

The visual inspection line is used as the final stage before cooling or packaging. It allows operators to inspect the French fries after they exit the oil-draining stage, ensuring they are free of defects such as black spots or unwanted debris.

⚙️ Smart operating mechanism:

1️⃣ Direct feed from the oil-draining shaker:

The inspection line is positioned directly after the shaker, conveying the French fries to the visual inspection stage before they enter the cooling or packaging process.

2️⃣ Dedicated work surface for manual inspection:

It provides ample space for operators to stand on either side of the line to visually inspect the French fries and remove any non-conforming pieces.

3️⃣ Targeted lighting (optional):

The line can be equipped with powerful, focused lighting to enhance visibility and inspection accuracy (available upon request).

4️⃣ Streamlined and durable design:

Made entirely of food-grade 304 stainless steel, making it perfectly suitable for wet and oily food processing environments.

5️⃣ Conveyor with industrial motor:

Equipped with a 1.125 kW motor operating at 380/220VAC – 50Hz, with the option to add an inverter for adjustable conveyor speed.

🛡️ Food-grade industrial design quality:

🔸 Professionally manufactured in Turkey to European standards

🔸 Made of food-grade 304 stainless steel, resistant to rust

🔸 Suitable for continuous operation in professional production lines

🔸 Easy to clean, maintain, and durable

📐 Technical Specifications:

Item Details

✅ Machine Number 015

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 1.125 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 130 cm

🔍 Features of the Visual Inspection Conveyor:

✔️ Accurate inspection of potato defects before cooling or packaging

✔️ Helps remove non-conforming products

✔️ Hygienic and safe design for manual operation

✔️ Maintains smooth and efficient production flow

✔️ Contributes to higher overall product quality

🎯 Who is this machine for?

For any factory that produces high-quality semi-processed potatoes and prioritizes inspecting the product before cooling and packaging to deliver a defect-free product suitable for commercial distribution.

🔧 Quality matters... because small details make a big difference.

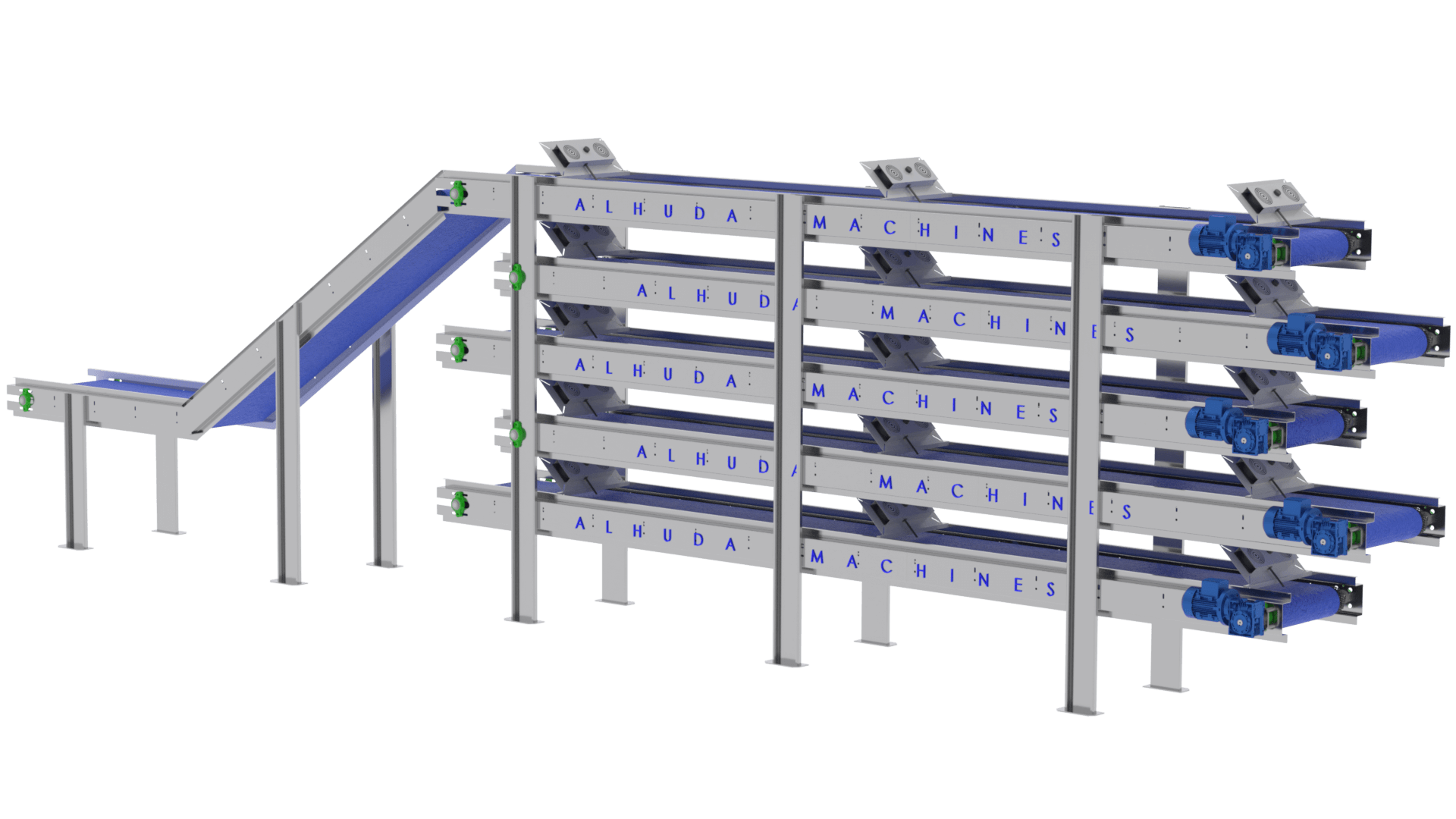

The process flow for cooling and storing potatoes

🌬️ A professional potato cooling and conditioning unit for perfectly prepared fries, ready for freezing

🍟 From the heat of frying... to the cool quality

The potato cooling and conditioning unit is a crucial post-frying stage. It gradually lowers the temperature of the fries to approximately +15°C before they enter the rapid freezing chamber. This stage is essential for maintaining the shape, preventing condensation or steam buildup inside the packaging.

⚙️ Advanced operating mechanism:

1️⃣ Intelligent multi-layer conveyor system:

The machine features 7 consecutive conveyor belts, moving the fries in a single layer, allowing for gradual cooling without any stacking or excessive pressure on the pieces.

2️⃣ High-performance cooling fans:

Equipped with a series of industrial fans that direct cool air currents across each layer, accelerating the cooling process evenly and naturally.

3️⃣ Full speed and direction control:

The movement of the fries between the layers is controlled by an intelligent drive system with an industrial inverter, allowing for adjustable speed and reversible direction as needed.

4️⃣ Automatic cleaning system:

Includes a self-cleaning mechanism that periodically removes residue, starch, and oil, preventing the fries from sticking and maintaining the cleanliness of the belts and the quality of the product.

5️⃣ Natural cooling before freezing:

Thanks to the layered system and fans, the fries reach a temperature of approximately +15°C, preparing them for the freezing chamber without any steam or moisture buildup inside the packaging later. 6️⃣ Space-Saving Design:

The machine's internal structure is designed vertically, saving considerable space in the production line without compromising cooling efficiency or operational flow.

🛡️ Food-Grade Industrial Design Quality:

🔸 Manufactured in Turkey to European standards

🔸 Entire structure made of food-grade 304 stainless steel, resistant to rust and oil

🔸 Designed for continuous operation, easy cleaning, and maintenance

🔸 All components are suitable for industrial and food processing environments

📐 Technical Specifications:

Item Details

✅ Machine Number 016

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 1.125 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 130 cm

✅ Number of Cooling Stages 7 consecutive cooling stages

✅ Target Temperature +15°C

✅ Cleaning System Automatic self-cleaning

🔍 Features of the Cooling and Drying Unit:

✔️ Gradual cooling to prevent condensation on the potato fries in the packaging

✔️ Prevents sticking or clumping of the fries before freezing

✔️ Space-saving design with high cooling efficiency

✔️ Automatic cleaning to maintain product quality

✔️ Adjustable speed and dwell time within the unit

✔️ Ready for immediate freezing or packaging

🎯 Who is this machine for?

For any food processing plant looking for a clean, dry, and non-sticky final product, ready for packaging or freezing under optimal hygienic conditions.

🔧 The cooling process isn't the end of the line... it's the beginning of sustainable quality.

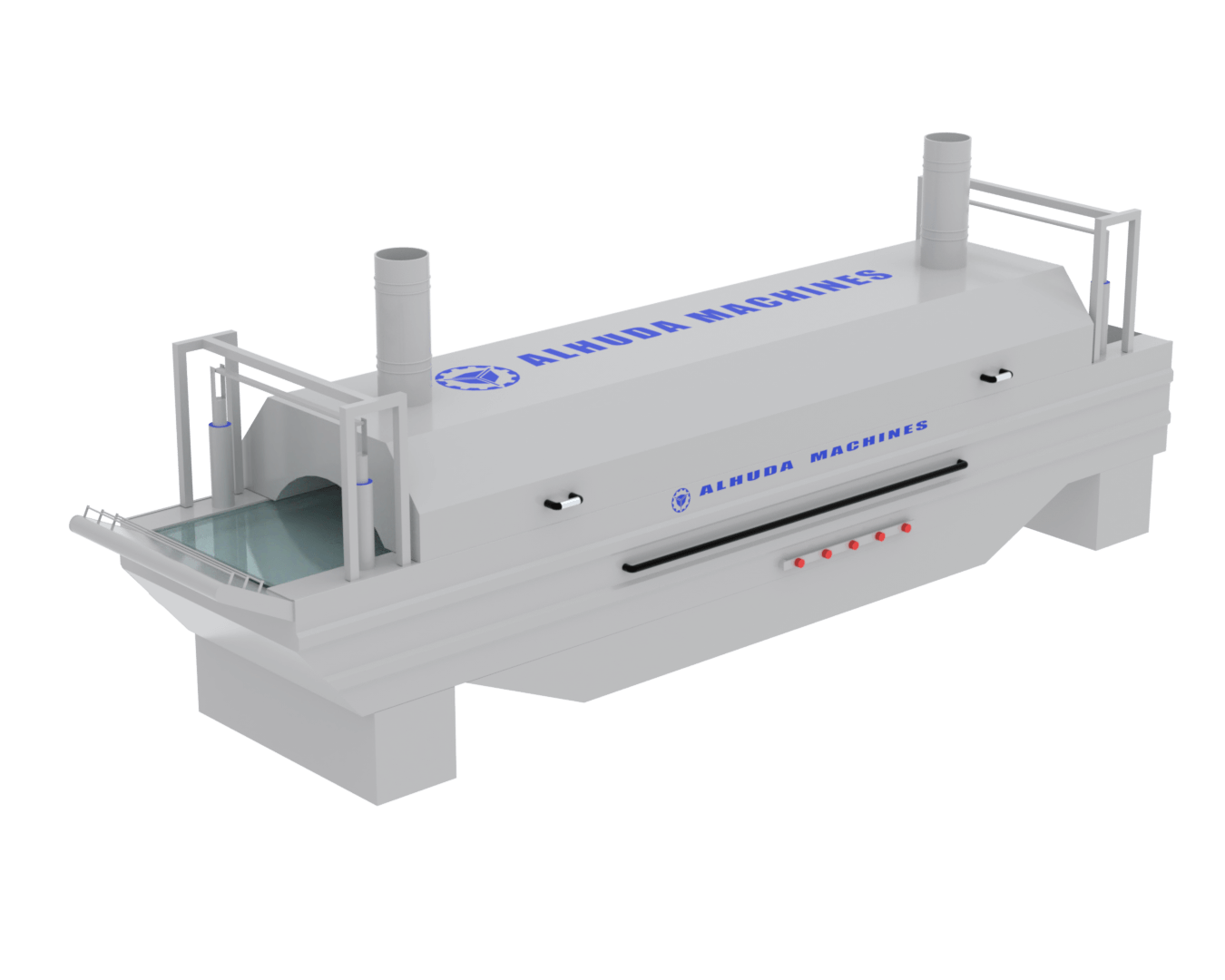

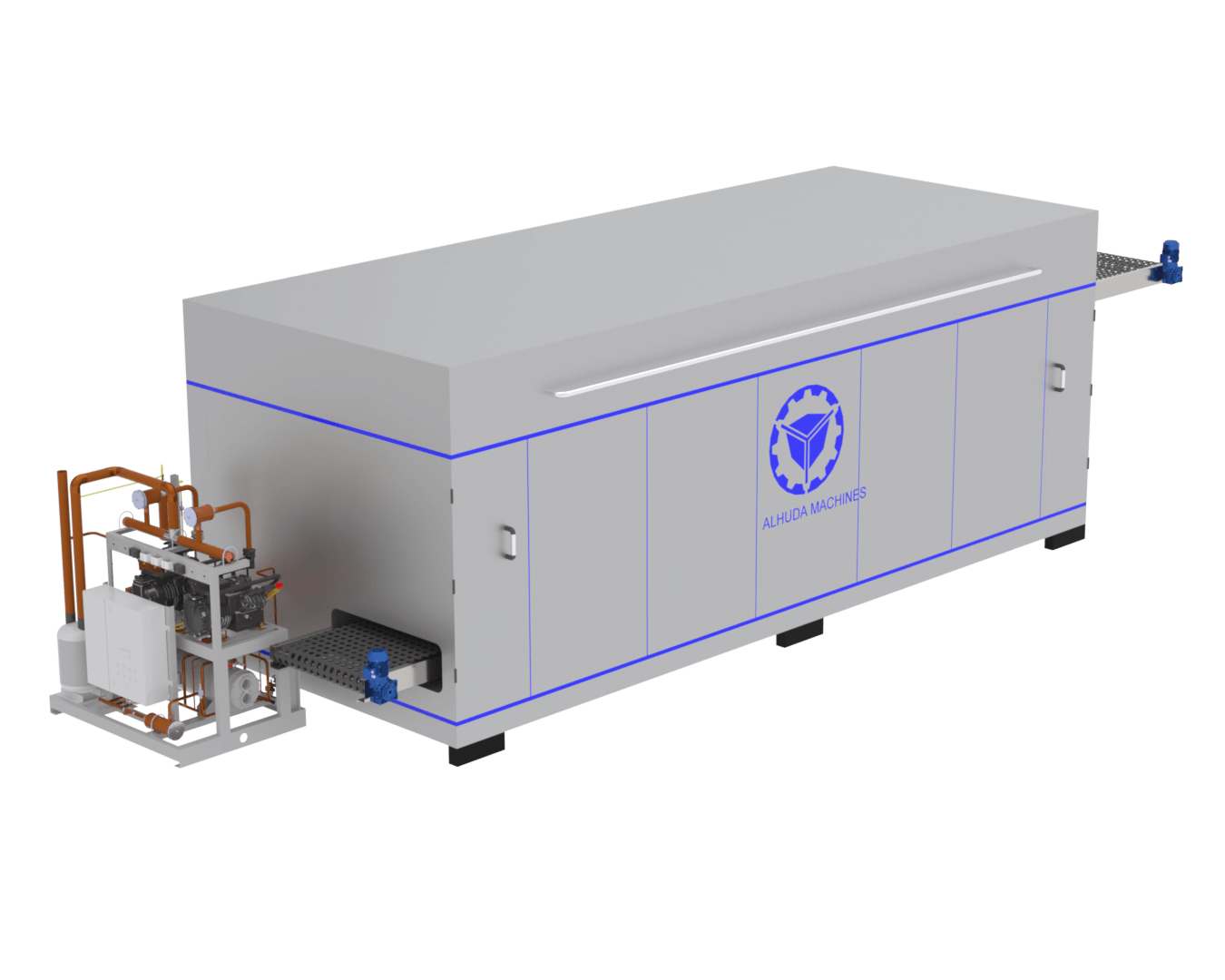

Cooling tunnel - Freezer Stun Chamber

❄️ Rapid Freezing Tunnel (Blast Freezer): Preserving Quality Starts with Professional Freezing

🍟 From production temperature... to a safe and healthy freezing point

The freezing tunnel (or blast freezer) is the crucial stage where the partially fried potato strips are frozen quickly and efficiently to preserve texture and flavor, prevent bacterial growth, and ensure the highest quality final product.

⚙️ Instant Freezing Mechanism – Precision Industrial Technology:

1️⃣ 130cm Wide Conveyor Belt

The potato strips are smoothly transported through the freezing chamber on an industrial-grade conveyor belt made of food-grade 304 stainless steel, designed to withstand extreme freezing conditions.

2️⃣ Adjustable Conveyor Speed – Industrial Inverter

Equipped with a powerful 7 HP motor and an inverter control unit to adjust the belt speed according to the product type and quantity, ensuring even freezing without any delays or clumping.

3️⃣ Inlet Temperature: +5°C – Outlet Temperature: -22°C

An optimal design to rapidly lower the temperature of the potato strips to -22°C, ensuring instant freezing that prevents any loss of texture, color, or flavor.

4️⃣ High-Quality Thermal Insulation – 15cm Panel with Internal Foam

The walls, ceiling, and floor of the tunnel are made of 15cm thick stainless steel sandwich panels, fully insulated with polyurethane foam to maintain the freezing temperature efficiently. 5️⃣ Stainless steel floor with integrated drainage channel

The tunnel floor is completely covered with 1mm thick stainless steel, with a specific slope designed to drain melting water through an integrated drainage channel, preventing water buildup and odors, and maintaining optimal hygiene.

🌀 Cooling Units – German Technology:

🔹 Evaporator:

Equipped with four industrial fans from Rosenberg, Germany

🔸 Rotation speed: 1400 RPM

🔸 Operating voltage: 380V

🔹 Condenser:

2 German (Rosenberg) fans

🔸 Rotation speed: 900 RPM

🔸 Equipped with comprehensive protection systems:

Gas pressure sensors (high/low)

Oil pressure protection

Pressure gauges for leak and malfunction detection

🔹 Compressor:

German or Italian, with built-in protection:

✅ Overcurrent protection

✅ Short circuit protection

✅ High-efficiency cooling system for rapid freezing

🧠 Intelligent Industrial Control System – PLC:

The freezing chamber is operated and controlled via a smart PLC-based control panel:

✔️ Fault display and alerts

✔️ Pressure and temperature monitoring

✔️ Operational scheduling

✔️ User-friendly for technicians

🛡️ European-quality food-grade construction:

🔸 Manufactured in Turkey to European standards

🔸 Entire exterior and interior made of food-grade 304 stainless steel

🔸 Thermal insulation + moisture and corrosion resistance

🔸 Hygienic design meeting US food safety standards

📐 Technical Specifications:

Item Details

✅ Machine Number 017

✅ Model ALEUDA-2024AS-M

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 180 kW

✅ Main Motor 7 HP (Inverter control)

✅ Voltage 380/220VAC – 50Hz

✅ Length: 15 meters

✅ Width: 350 cm

✅ Height: 300 cm

✅ Incoming product temperature: +5°C

✅ Outgoing product temperature: -40°C

✅ Production capacity: 7000 kg/hour

✅ Insulation thickness: 15 cm (foam + panel + stainless steel)

✅ Refrigeration systems: German/Italian (Rosenberg)

🔍 Features of the rapid freezing tunnel:

✔️ Instant freezing to preserve shape, taste, and texture

✔️ Smart water drainage system to prevent water accumulation and odors

✔️ Highly efficient thermal insulation

✔️ Intelligent control and full monitoring via PLC

✔️ Continuous operation capability within production lines

✔️ Easy cleaning and maintenance

✔️ Compliant with international food safety standards

🎯 Who is this machine for?

For any industrial facility aiming to produce pre-fried potatoes with a long shelf life and without any loss of quality, the rapid freezing tunnel is the crucial final step that determines product quality and shelf life.

🔧 Proper freezing... is the key to market success.

Gravimetric packaging machines continuity system 1pc

📦 7/24 Hassas Paketleme için Otomatik Akıllı Ağırlık Paketleme Makinesi

🍟 Yarım Kızarmış Patates Dilimlerinin Hızlı, Güvenilir ve Sıkı Paketlenmesi

Ağırlık paketleme makinesi, yüksek verimli üretim hatlarının gereksinimlerini karşılamak üzere en yeni otomatik kontrol teknolojisi kullanılarak tasarlanmıştır.

Servo motorlar, hassas bir tartım sistemi ve akıllı bir kontrol arayüzü sayesinde dengeli, atıksız paketleme ve sürekli üretim hatlarıyla optimum uyumluluk sağlar.

⚙️ Akıllı Çalışma – Hassasiyet + Hız + Güvenlik:

1️⃣ Tam Servo Tahrik Sistemi:

Tüm hareket, tartım ve çekme fonksiyonları, yüksek hassasiyetli servo motorlar tarafından desteklenir ve çalışma sırasında anında kontrol ve optimum tepki sağlar.

2️⃣ Endüstriyel Kontrol Ünitesi – Delta PLC:

Son derece duyarlı bir endüstriyel PLC işlemci tarafından desteklenen gelişmiş bir kontrol sistemi, tüm makine bileşenlerini yönetir ve kesintisiz, istikrarlı bir çalışma sağlar.

3️⃣ Gelişmiş 10 inç DELTA Dokunmatik Ekran:

10 inç elektronik dokunmatik ekrana sahip basit ve sezgisel kullanıcı arayüzü, teknisyenin işlevleri izleyip ayarlamasını ve anında uyarıları görüntülemesini sağlar.

4️⃣ Akıllı Çok Başlıklı Tartım Sistemi:

Her paketin ağırlığını otomatik olarak belirlemek, optimum dengeyi sağlamak ve israfı önlemek için yüksek hassasiyetli bir elektronik tartım sistemine dayanır.

5️⃣ Otomatik Rulo Çekme ve Ayarlama Sistemi:

– Rulo yükleme merdivenini otomatik olarak hareket ettirmek için bir adım motoru ile donatılmıştır.

– Rulo çekimini telafi etmek için başka bir adım motoru.

– Ani kapanmaları önlemek için rulo tamamlanmaya yaklaştığında otomatik uyarı.

6️⃣ Dahili Güvenlik Sistemleri:

Makine, operatörü çalışma sırasında tehlikelerden koruyan ve açılma veya arıza durumunda çalışmayı engelleyen endüstriyel güvenlik sensörleri ile donatılmıştır.

7️⃣ Detaylı Üretim Sayaçları:

– Miktarları izlemek için günlük sayaç.

– Toplam üretim sayacı.

– Verileri yönetim sistemlerine bağlama olanağı. Fabrikalar

8️⃣ Hazır Paketler için Konveyör Bant + Dahili Tarih Yazıcısı:

– Kapatıldıktan sonra paketlerin sorunsuz taşınması

– Ambalaj etiketleri için otomatik üretim ve son kullanma tarihi yazıcısı (talep üzerine)

🛡️ Gıda Endüstrisi Üretim Kalitesi:

🔸 Avrupa standartlarına uygun Türk üretimi

🔸 Yağ ve neme dayanıklı, gıdaya uygun 304 paslanmaz çelikten üretilmiş tüm gövde

🔸 Ürünle temas eden tüm parçalar gıda güvenliği yönetmeliklerine uygundur

🔸 7/24 kesintisiz çalışma için tasarlanmıştır

📐 Teknik Özellikler:

Ürün Detayları

✅ Makine No. 018

✅ Model ALEUDA-2024AS-M

✅ Üretim Ülkesi: Türkiye 🇹🇷

✅ Malzeme: Gıdaya uygun 304 paslanmaz çelik

✅ Güç: 5,25 kW

✅ Voltaj: 380/220 VAC – 50 Hz

✅ Uzunluk: 230 cm

✅ Genişlik: 130 cm

✅ Yükseklik: 200 cm

✅ Rulo tipi: Entegre selofan

✅ Delta kontrol ekranı – 10 inç dokunmatik ekran

✅ Delta endüstriyel PLC kontrol ünitesi

✅ Tartım sistemi: Elektronik tartım başlığı seti

✅ İstenilen ağırlığa göre üretim hızı

✅ Dahili tarih yazıcısı (istek üzerine)

🔍 Tartımlı paketleme makinesinin özellikleri:

✔️ Yüksek tartım hassasiyeti israfı önler

✔️ Tek bir ekrandan tüm aşamaların akıllı kontrolü

✔️ Tüm hatla uyumlu üretim hızı

✔️ Emniyet ve güvenlik sistemi

✔️ Temiz ve bakımı kolay tasarım

✔️ Her türlü kağıt veya plastik kap için uygundur

🎯 Bu makine kimler için?

Doldurma hızı, tartım Hassasiyet ve kesintisiz, sorunsuz çalışma sağlayan bu tartımlı paketleme makinesi, yüksek performanslı bir üretim ortamında profesyonel paketleme için kapsamlı bir çözüm sunar.

🔧 Paketleme, kaliteyi ve pazarlanabilirliği koruyan son dokunuştur.

Electrical parts and control panels

Circuit breakers: Schneider brand

Contactors: Schneider brand

Control panel: Delta

Inverters: Delta

Motors: GAMAK

Speed reducers: YILMAZ

Or as per customer request

Basic information

🏭 Semi-Fried Potato Production Line – by Al Huda Industrial Company

Made in Turkey – German Technology – Global Standards

Al Huda Industrial Company offers state-of-the-art semi-fried potato production lines featuring advanced European technology, ensuring superior product quality, high operational efficiency, and long-term durability.

This production line is designed to meet the needs of food processing plants and ambitious investors, adhering to the highest standards of hygiene, food safety, and industrial reliability.

📌 Key Information about the Line:

Item Value

🔸 Total Line Length Approximately 100 meters

🔸 Line Width Approximately 4 meters

🔸 Required Area Approximately 700 square meters

🔸 Approximate Electricity Consumption 150 kWh for the production line + 180 kWh for the freezer

🔸 Heat Source (Oil/Gas Boiler) Consumes 25 liters/hour during the first hour

🔸 Number of Required Workers Only 8 to 10 workers are needed to operate the entire line

🔸 Production Capacity Up to 7 tons per hour, depending on machine settings

🛠️ Detailed Explanation of All Stages and Components of the Production Line:

1️⃣ Potato Sorting and Inspection Machine – Code 003

🔹 Sorts potatoes to detect and remove damaged ones

🔹 Equipped with automatic outlets to separate unsuitable potatoes

🔹 Made entirely of food-grade 304 stainless steel

2️⃣ Potato Washing and Conveyor Belt – Code 004

🔹 Integrated with a water tank

🔹 Conveyors the potatoes to the cutting stage

🔹 Operates smoothly to ensure continuous flow without clumping

3️⃣ Graduated Sorting Vibrator – Code 005

🔹 Vibrates the potatoes through 4 gradual stages

🔹 Prevents random feeding and protects the cutter from clogging

4️⃣ Cutter Feeder – Code 006

🔹 Regulates the flow of potatoes into the cutter

🔹 Prevents damage caused by irregular feeding

🔹 An essential component for synchronizing the machines

5️⃣ Belgian FAM Potato Cutter – Code 007

🔹 Cuts potatoes into uniform sizes

🔹 High precision and quality cutting without damage

🔹 Low energy consumption and professional performance

6️⃣ Conveyor Belt with Integrated "Jacuzzi" Washing Tank – Code 008

🔹 Washes sliced potatoes to remove starch

🔹 Double washing system + direct lift to the grading machine

7️⃣ Grading conveyor belt – Code 009

🔹 Separates very small and unwanted pieces

🔹 Ensures uniform size of potato slices

🔹 Made of food-grade polyamide and stainless steel rollers

8️⃣ Starch removal machine (blancher) – Code 010

🔹 Removes sugars and starch from the slices

🔹 Uses a whirlpool system + air pressure + water sprays

🔹 Full control of speed and time + safe hydraulic system

9️⃣ Vibrating separator and water-draining machine – Code 011

🔹 Vibrates at high speed to separate stuck pieces

🔹 Removes excess water before the drying stage

10️⃣ Hot air drying system – Code 012

🔹 Uses hot air + 6 fans to dry the moisture

🔹 Enhances crispness and prevents oil contamination during frying

🔹 Closed thermal circuit for faster heating

11️⃣ Continuous fryer – Code 013

🔹 Precise initial frying at a controlled temperature

🔹 Uses an external heat exchanger to protect the oil

🔹 Equipped with 6 hydraulic agitators + PID control

🔹 Three-stage oil filtration system + two 800-liter tanks

🔹 Equipped with an electrical emergency system to prevent burning

🔹 The best point in the line in terms of technology and safety

12️⃣ Oil-draining vibrator – Code 014

🔹 Separates excess oil from the potatoes

🔹 Prevents sticking or breakage

🔹 Operates in four gradual stages

13️⃣ Quality control conveyor belt – Code 015

🔹 Allows for inspection of the finished product Manually

🔹 Removal of black spots or defects before packaging

1️⃣4️⃣ Potato Cooling and Conditioning System – Code 016

🔹 Consists of 7 layers with a smart speed control system

🔹 Equipped with cooling fans to maintain temperatures up to 15°C

🔹 Features an automatic cleaning system

1️⃣5️⃣ Freezing Tunnel or Blast Freezer – Code 017

🔹 Freezing temperature down to -22°C

🔹 High cooling capacity and German components (Rosenberg)

🔹 Includes: evaporator, condenser, compressors, and a PLC control panel

🔹 Sloping stainless steel floor for drainage – 15cm thick foam insulation

🔹 130cm wide internal conveyor belt

1️⃣6️⃣ Automatic Weighing Packaging Machine – Code 018

🔹 Multi-head precise weighing system

🔹 PLC control – DELTA touchscreen – date printer

🔹 Fully servo-driven design for continuous operation

🔹 Operates 24/7 without interruption

🔹 Ideal packaging in sealed cellophane bags

✅ Why choose Al Huda's potato processing line?

✔ Turkish-made with European standards and German technology

✔ Integrated design ensures continuous operation and high efficiency

✔ Smart control at every stage, from washing to packaging

✔ After-sales service: installation + training + maintenance + continuous technical support

✔ Trial operation at the company's facility – Gaziantep

✔ Full refund guarantee if the line does not meet specifications

✔ Suitable for large-scale industrial investment and export projects

🧪 Testing and Operational Guarantees:

🔧 Before shipment, the entire line is fully tested and operated at the factory to ensure that every component is fully functional. 📋 Detailed performance reports and operational videos are provided.

📜 Our production line holds internationally recognized quality certifications.

📞 Contact us now to receive a complete feasibility study and a detailed plant and space layout plan.

Al-Huda Company – Generations of experience, cutting-edge technology.