Natural potato chips production line

🌟 Your Golden Business Opportunity: A Natural Potato Chips Manufacturing Plant 🌟

Your Real Chance in the Profitable Food Industry

🚀 Introduction:

In a world where priorities change rapidly, the food industry remains one of the most stable and profitable sectors.

No matter how markets and trends evolve, the demand for food remains constant... and that's where your golden opportunity lies.

Today, we present to you a business project that is among the best in terms of demand, distribution speed, and sustainable profits.

🥔 What is this project?

It's a plant for producing natural potato chips – a product that needs no introduction!

People love it, consume it daily, and demand it in homes, stores, cafes, and even schools.

What makes this project unique?

✔️ A well-known product

✔️ Frequent consumption

✔️ No need to convince customers

✔️ Appeals to all ages and social classes

✔️ Excellent profitability

✔️ Easy marketing and distribution

✅ Why is this project profitable and guaranteed?

Let's be honest…

Yes, there are large companies in the market, but does that mean the market is saturated?

The answer: Absolutely not.

🔸 Markets still demand more

🔸 There is a clear shortage of high-quality local products

🔸 Consumers are always looking for better quality at a reasonable price

🔸 And above all, loyalty in this market is built on taste, packaging, and availability, not just the company name.

If you can offer a superior product, you can enter the market strongly and achieve daily profits.

📌 In addition:

A highly scalable project

Moderate capital investment compared to other projects

Machinery is available in both local and international markets

Raw material (potatoes) is available year-round

No high-level technical expertise required to operate the plant

You can start with small-scale production and gradually grow

💼 A word for the smart investor:

If you are looking for a real investment opportunity, this project is right here.

But let me tell you something very important:

> Successful projects don't start with just an idea, but with a sound feasibility study.

Yes, a detailed feasibility study may cost you $1,000 or even $3,000,

but it gives you a very accurate picture of:

🔍 Market size

📊 Expected profits

⚠️ Challenges

💡 Opportunities

🎯 Unique selling points

Every dollar you invest in the study will return many times over in operations and production.

💡 Imagine this scenario:

Your product enters the market and competes successfully within the first 3 months

You secure distribution contracts with supermarkets and local stores

You increase production as demand doubles

After a year, you start exporting your product to one or two countries

And in just two years, your brand becomes well-known and popular

Is this just a dream?

Absolutely not…

It is a very realistic possibility if you start the right way.

🎯 Conclusion:

A potato chip factory project isn't just an idea, but a ready-to-implement opportunity for those with the courage and a smart investment mindset.

Think about this:

"How many times have you seen a new product enter the market and achieve huge sales in a short time?"

The secret isn't luck, but choosing the right project and executing it meticulously.

✨ Don't wait any longer… this is your opportunity.

🔑 Make the decision and take the first step towards building your profitable business.

Would you like me to prepare for you now:

A preliminary feasibility study?

A detailed business plan?

A marketing proposal for your project?

I am ready to assist you at any stage of the process.

Your ideal partner: Al-Huda Company

The line consists of the following parts

1. Besleyici, kozmetik tankı ve konveyör bant

2. İki kademeli patates yıkama makinesi

3. Toplama hazneli konveyör bant

4. İki kademeli patates soyma makinesi

5. Patates muayene konveyör bant

6. Konveyör bant

7. Patates ayıklama vibratörü

8. Dilimleme besleyici

9. Patates kesme makinesi

10. Nişasta çıkarma haşlama makinesi

11. Su kurutma vibratörü ve patates dilim ayırma

12. Hava kurutma tüneli

13. Sürekli kızartma makinesi

14. Yağ kurutma vibratörü

15. Muayene konveyör bant

16. Baharatlama makinesi

17. Baharatlama silindiri

18. Paketleme makinesi konveyör bant

19. Paketleme makineleri

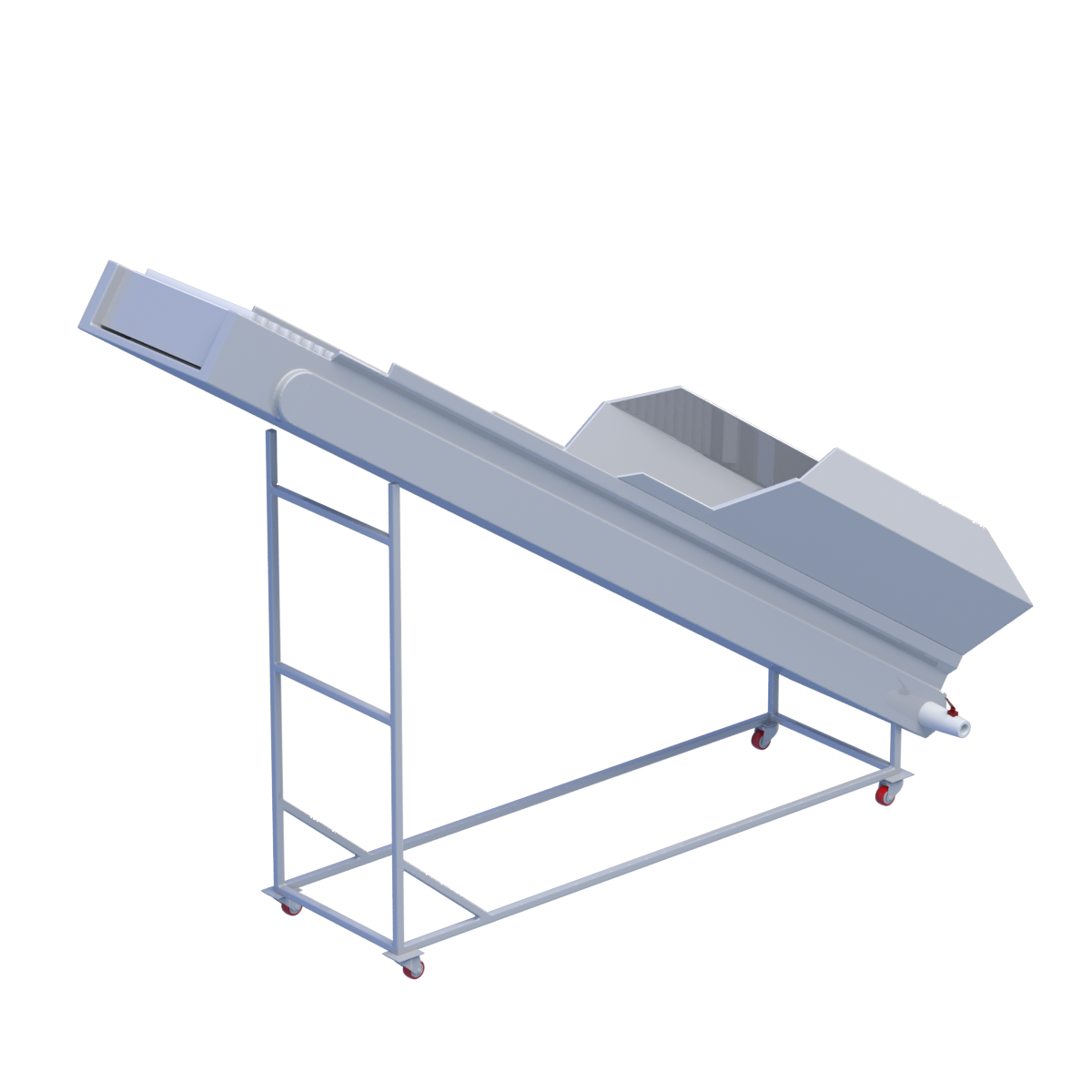

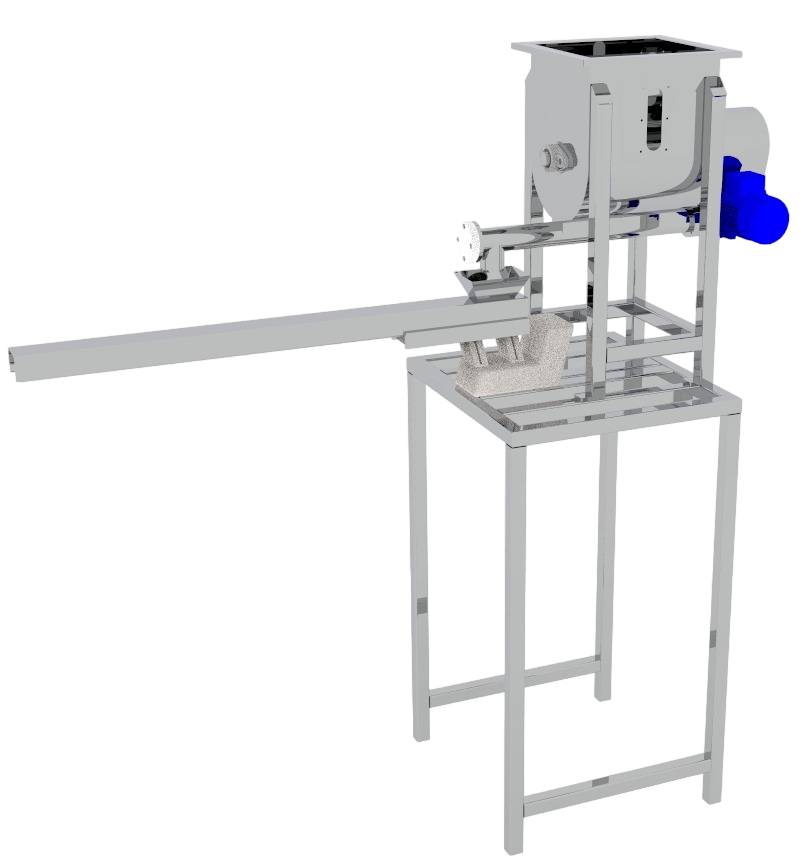

ASSEMBLY TANK FEEDER WITH CONVEYOR BELT

The efficient potato collection and conveying process is a crucial stage in the potato processing line. The collection tank and conveyor system ensures the smooth and efficient transfer of potatoes to the washing line, thus optimizing the overall production process.

Advanced Features:

1️⃣ Safe and reliable potato collection and conveying system

✔️ The collection tank is designed with a large capacity to accommodate significant volumes of potatoes.

✔️ Potatoes are conveyed smoothly and evenly, without any damage or bruising.

2️⃣ Durable construction using food-grade stainless steel

✔️ Made entirely of food-grade 304 stainless steel for maximum hygiene and quality.

✔️ Resistant to corrosion and harsh industrial conditions, ensuring a long lifespan.

3️⃣ Energy-efficient operation

✔️ Powered by a high-efficiency electric motor for smooth and reliable potato conveying.

✔️ Operates on 380/220V – 50Hz power supply with low energy consumption.

4️⃣ Robust frame for durability and stability

✔️ Constructed with 10x10 cm 304 stainless steel profile for strength and stability during operation.

✔️ 3 mm thick stainless steel side panels for enhanced durability.

5️⃣ User-friendly design for easy operation and maintenance

✔️ Equipped with adjustable, stable legs for secure operation.

✔️ Easy disassembly and assembly for efficient maintenance and cleaning. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Power: 3.75 kW | 380/220 V | 50 Hz ✅ Dimensions:

Length: 450 cm

Width: 150 cm

Height: 420 cm

✅ Part Number: 001

Model: THV-2024PV-B

✅ Country of Origin: Turkey – High-quality industrial product manufactured according to European standards. Features of the conveyor belt with collection tray:

✔️ Durable and rust-resistant design for long-lasting performance.

✔️ Gentle transport to prevent damage to the potatoes.

✔️ Safe and energy-efficient operation with full control over the conveyor speed.

✔️ Easy maintenance and cleaning for maximum operational efficiency.

💡 The ideal solution for safe and smooth potato transport within your production line!

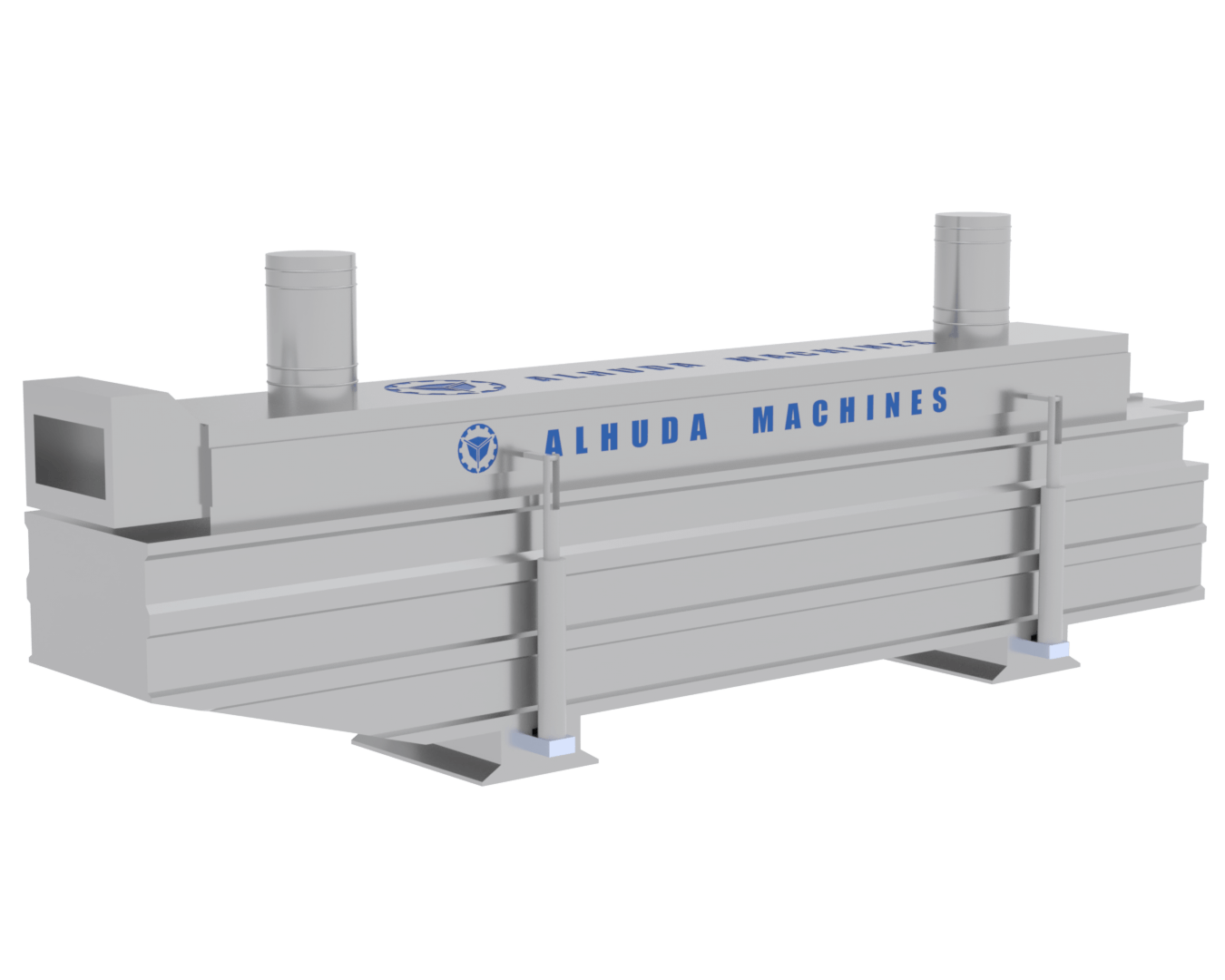

Potato washing machine

Perfect hygiene and product quality start with the first step

The two-stage potato washing machine is a crucial first step in the potato chip or French fries production line. Cleanliness and washing quality are not just a matter of hygiene; they are essential for ensuring consistent taste, improving operational efficiency, and maintaining the integrity of the entire production line.

⚙️ What does this machine do?

The potato washing machine cleans potatoes thoroughly, removing all dirt and impurities before they enter the cutting and frying stages.

It uses a two-stage cleaning system to guarantee the removal of even the finest dirt, even under the harshest supply conditions.

💡 Its professional operating mechanism:

1️⃣ First washing stage

The potatoes are passed through a high-pressure water washing system, which removes dirt and any unwanted surface layers.

2️⃣ Scrubbing and polishing stage

The potatoes then pass over specially designed, soft, synthetic brushes, ensuring thorough cleaning while preserving the outer skin (or as per the production line requirements).

🛡️ Reliable industrial quality:

🔹 High-quality Turkish manufacturing,

🔹 Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion,

🔹 Easy to disassemble, clean, and maintain,

🔹 Designed to withstand long hours of operation in demanding environments. 📐 Technical Specifications:

Item Details

✅ Machine Number 002

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 5.25 kW

✅ Voltage 380/220 VAC

✅ Length 550 cm

✅ Width 120 cm

✅ Height 180 cm

🔍 Features of the Potato Washing Machine:

✔️ Two-stage cleaning for thorough and precise removal of dirt

✔️ Ideal preparation of potatoes before cutting

✔️ Maintains the quality of the raw material before processing

✔️ Reduces downtime and maintenance due to dirt or impurities in the production line

✔️ Easy to operate and maintain

✔️ Designed to meet hygiene and safety standards in food processing plants

✔️ Ideal for medium and large-scale production facilities

✔️ Ensures a clean and hygienic production environment from the very first step

🎯 Who is this machine for?

If you strive to produce high-quality potatoes with a pure taste and perfect texture from the very beginning – the THV-2024PV-B potato washing machine is an essential addition to your production line. Start with a clean process and invest in a machine that guarantees a product worthy of consumer trust.

Conveyor belt line with collecting basin

Precise cleaning and automatic potato transport to the peeling stage

🚿 The most important preparation stage in the production line

The integrated potato washing unit, part of the conveyor system, is a crucial step in the potato chip or French fry production line. It ensures:

✅ Removal of dirt and impurities

✅ Preparation of the potatoes for the peeling stage

✅ Cleanliness of the raw material before mechanical processing

This integrated system increases production line efficiency and saves time and effort by combining two processes into one machine.

⚙️ How it works:

1️⃣ Effective washing with flowing water

The potatoes are submerged in the wash tank, where a strong, balanced stream of water removes dirt and mud.

2️⃣ Automatic transport to the peeling machine

After washing, the integrated conveyor belt automatically transports the potatoes to the peeler, eliminating the need for manual handling and ensuring a smooth and efficient production flow. 🛡️ High-Quality Industrial Equipment:

🔸 Professionally manufactured in Turkey

🔸 Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion

🔸 Parts that come into contact with food are made of safe, food-grade chrome

🔸 Easy-to-clean design, adhering to the highest food safety standards

📐 Technical Specifications:

Item Details

✅ Machine Number 003

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel + food-grade chrome

✅ Power 3.75 kW

✅ Voltage 380/220 VAC

✅ Length 280 cm

✅ Width 120 cm

✅ Height 260 cm

🔍 Features of the Washing Tank with Conveyor Belt:

✔️ Ideal for washing potatoes with running water

✔️ Automatic transfer to the peeling machine

✔️ Reduces manual labor and speeds up production

✔️ Ensures cleanliness and quality of the raw material before peeling

✔️ Made entirely of safe, food-grade materials

✔️ Easy to disassemble, maintain, and clean

✔️ Supports a smooth workflow within your potato processing line

🎯 Is it suitable for your production line?

If you are looking for a smart and integrated machine that provides efficient washing and automatic transfer without wasting time or effort, the Washing Tank with Conveyor Belt – THV-2024PV-B is an ideal choice for small, medium, and large production lines.

Start your production line with meticulous cleanliness and high efficiency… and make quality your hallmark from the very first step.

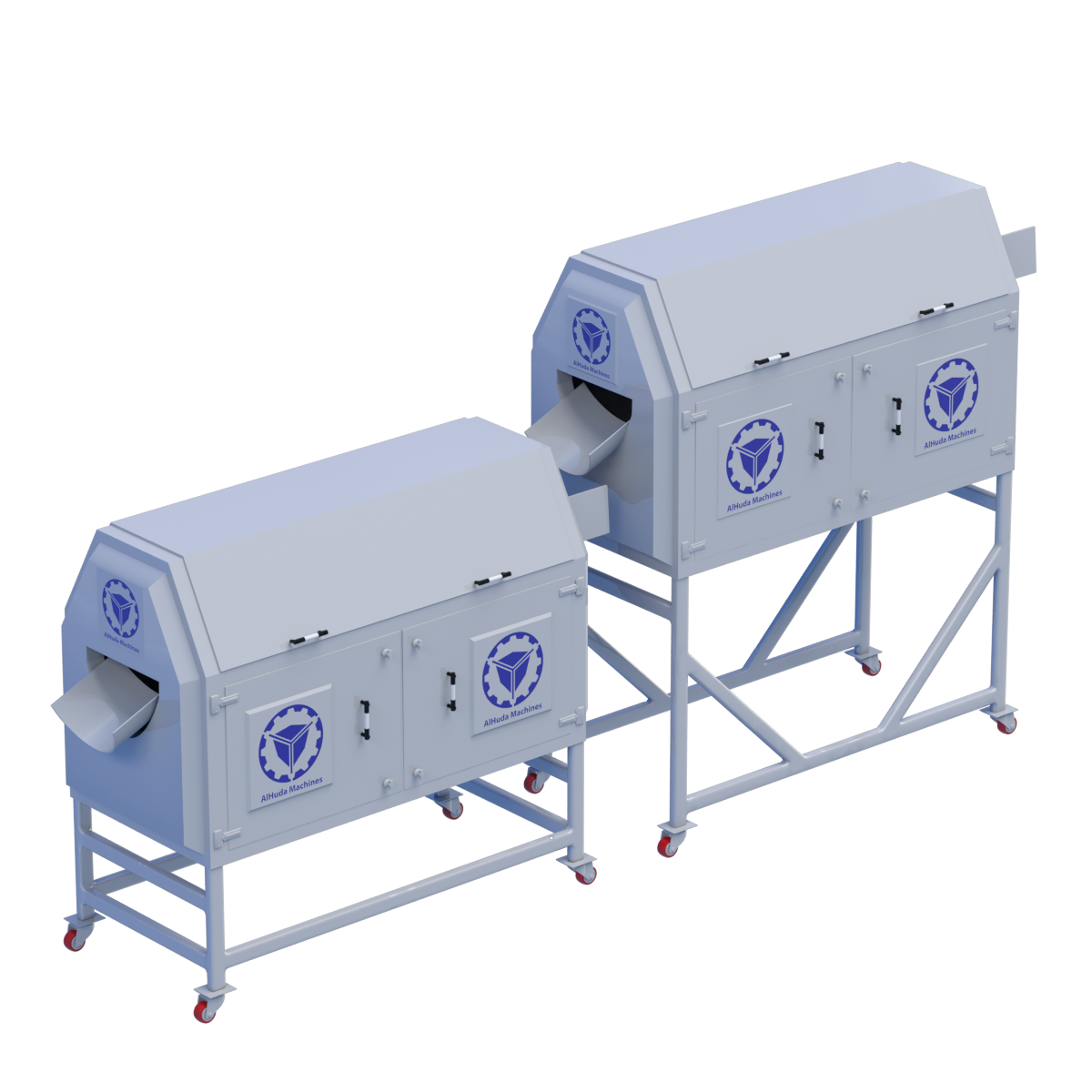

Potato peeling machine

Smart peeling with brush technology… less waste, higher quality

🧼 A crucial step in the production line

The potato peeling machine is one of the most important stages in preparing potatoes before they enter the processing line, whether for producing potato chips, French fries, or frozen products.

What truly sets this machine apart is its advanced peeling system, which focuses on removing only the peel, without wasting any of the potato flesh, thus increasing efficiency and reducing waste.

🧽 Professional operating mechanism with an advanced brush system:

1️⃣ Rotating disc with brushes

The machine operates using a central disc that rotates continuously at 360 degrees, with bars covered in soft, synthetic brushes.

2️⃣ Peeling and polishing simultaneously

During rotation, the potatoes are repeatedly rolled between the brushes, ensuring gentle peeling without affecting the shape of the potatoes or causing excessive waste.

3️⃣ "Brush Peeling" system

Also known as "Soft Brush Peeling," this system is used in advanced food industries to guarantee a smooth, shiny product, perfectly prepared for the next stage of processing. 🛡️ High-Quality Construction:

🔸 Professionally manufactured in Turkey with precision engineering

🔸 Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion

🔸 Reliable peeling system with long lifespan and minimal maintenance requirements

🔸 Safe and easy-to-clean design, ideal for food processing environments

📐 Technical Specifications:

Item Details

✅ Machine Number 004

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 10.5 kW

✅ Voltage 380/220VAC – 50Hz

✅ Length 500 cm

✅ Width 140 cm

✅ Height 250 cm

🔍 Features of the Potato Peeler:

✔️ Gentle and precise peeling with minimal waste

✔️ Advanced technology using soft, synthetic brushes

✔️ Continuous agitation ensures consistent results for every potato

✔️ Maintains potato shape and gives them a polished appearance

✔️ Robust industrial design for long-term operation

✔️ Easy to maintain and clean

✔️ Ideal for high-quality production lines

🎯 Who is this machine for?

This machine is designed for those who want to produce potatoes with a clean appearance and excellent texture, while preserving the maximum amount of the original potato weight.

It's a smart investment that reduces waste, improves the final product quality, and adds a professional touch to every potato that passes through it.

Start your production line with "smart peeling"...

🔑 Because the quality of the beginning determines the quality of the end.

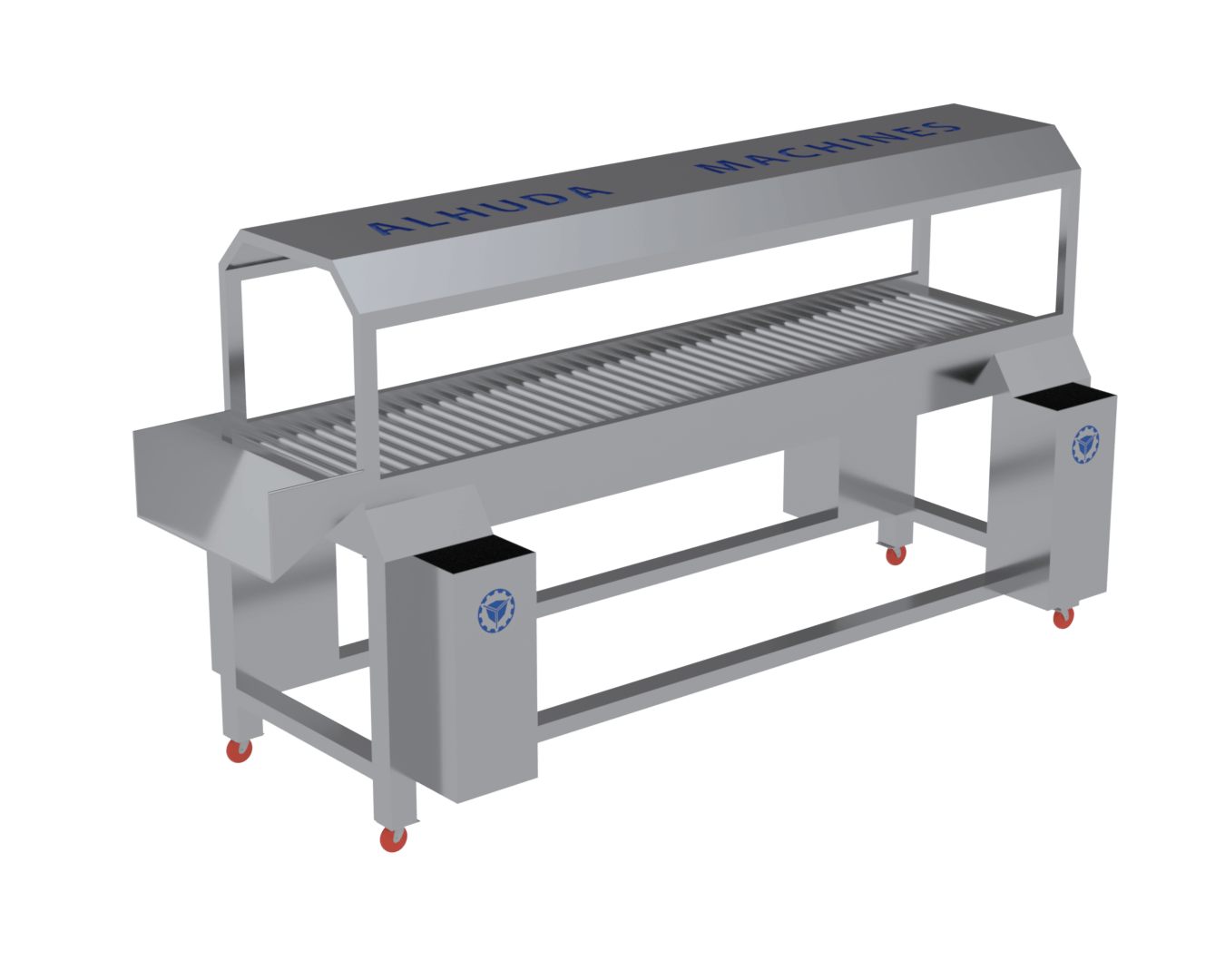

Roller conveyor line for potato inspection

Precise inspection to remove unsuitable potatoes… for the highest quality and food safety

🧾 Visual inspection stage… an essential step

In potato processing lines, the potato inspection stage is a vital and essential step to ensure a clean, uniform, and defect-free final product.

The inspection conveyor belt rotates the potatoes continuously, allowing operators or an automated inspection system to easily and effectively identify and remove any damaged or unsuitable potatoes.

⚙️ Smart operating mechanism:

1️⃣ Rotating conveyor belt for comprehensive inspection

The potatoes are placed on a conveyor belt equipped with rotating rollers that turn each potato as it moves along, allowing it to be inspected from all angles.

2️⃣ Removal of unsuitable potatoes into a dedicated bin

As soon as any unsuitable potato (with spots, damage, mold, etc.) is detected, it can be manually or automatically removed through special openings leading to a bin located below the conveyor belt, without disrupting the production flow.

3️⃣ Continuous and uninterrupted flow

The smart design ensures continuous operation while guaranteeing real-time removal of rejected potatoes, thus maximizing operational efficiency.

🛡️ Reliable Manufacturing Quality:

🔸 High-quality Turkish manufacturing

🔸 Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion

🔸 Ergonomic design for easy maintenance and cleaning

🔸 Suitable for use in food processing plants that require the highest hygiene and safety standards

📐 Technical Specifications:

Item Details

✅ Machine Number 005

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 160 cm

🔍 Features of the Inspection Conveyor Belt:

✔️ Continuously rotates potatoes for thorough inspection from all sides

✔️ Equipped with collection bins for defective potatoes

✔️ Maintains uninterrupted production flow

✔️ Open design for easy cleaning and maintenance

✔️ Reduces waste in later production stages

✔️ Ideal for production lines focused on quality and professional sorting

🎯 Who is this conveyor belt for?

If you strive to deliver a clean, high-quality final product, integrating an inspection conveyor belt into your production line is a smart investment.

It helps you identify defects before they become costly, demonstrating your commitment to product quality and customer satisfaction.

Start improving quality from the very beginning…

🔍 Because even the smallest details make a difference in competitive markets.

Conveyor line

Smooth and consistent transport of potatoes to the cutting stage… efficiently and reliably

💧 A dual role in the production line

The water tank integrated into the conveyor belt is a key element for controlling the flow of potatoes after peeling and before cutting.

It combines two essential functions:

1. Submerging the potatoes in water to preserve their quality.

2. Lifting and feeding them into the cutting machine smoothly and without any jams or stoppages.

This machine ensures a continuous and smooth flow, maintaining the balance of the production line, which reduces downtime and improves the cutting quality.

⚙️ A practical and efficient operating mechanism:

1️⃣ A water tank of the right depth

The potatoes are submerged immediately after peeling to maintain their natural color and prevent oxidation before cutting.

2️⃣ An integrated conveyor system for lifting the potatoes

The conveyor automatically lifts the potatoes from the tank towards the cutting machine at a controlled speed, ensuring a balanced flow to the cutting stage.

3️⃣ Consistent transport without any buildup

This system helps to distribute the potatoes evenly, making the cutting machine's performance more precise and efficient. 🛡️ High-Quality Construction:

🔸 Reliable Turkish manufacturing

🔸 Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion

🔸 Ergonomic design prioritizes hygiene and ease of maintenance

🔸 Suitable for food processing environments requiring high hygiene standards

📐 Technical Specifications:

Item Details

✅ Machine Number 006

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 280 cm

✅ Width 120 cm

✅ Height 180 cm

🔍 Features of the Water Tank with Conveyor Belt:

✔️ Prevents discoloration of potatoes before cutting

✔️ Ensures efficient and consistent feeding of potatoes into the cutting machine

✔️ Prevents material buildup and improves workflow

✔️ Made entirely of food-safe materials

✔️ Easy to clean and maintain

✔️ Reduces unexpected downtime or errors during the cutting process

🎯 Who is this machine for?

For any food processing facility aiming to produce high-quality, uniform products, integrating a water tank with a conveyor belt is a smart move to ensure smooth production flow and consistent cutting and packaging results.

Transport your potatoes smoothly, efficiently, and professionally…

🔧 Because efficient production starts with smart equipment.

Mechanical vibrator for potato feeding

Gradual sorting and professional handling of potatoes before cutting

📦 Precise and intelligent control of potato flow

The vibratory conveyor is a crucial component in the potato processing line, as it sorts and arranges the potatoes gradually before they enter the cutting machine or other processing stages.

Thanks to its advanced vibration system and four-stage sorting process, the conveyor prevents clumping and ensures a precise, consistent feed rate.

⚙️ Smart operating mechanism:

1️⃣ Four-stage gradual movement

The conveyor moves the potatoes through four successive stages. Each stage contributes to distributing the potatoes and breaking up any clumps, facilitating a smooth and orderly flow to the subsequent machines.

2️⃣ High-frequency vibration

The conveyor utilizes a robust industrial vibration system that allows the potatoes to move smoothly without sticking together, improving efficiency and reducing waste.

3️⃣ Dedicated path for precise feeding

The conveyor belt is designed to direct the potatoes to the cutting or inspection machine in controlled quantities, preventing malfunctions caused by inconsistent feeding. 🛡️ Durable and Safe Manufacturing Quality:

🔸 Professionally manufactured in Turkey

🔸 Made entirely of food-grade 304 stainless steel, resistant to rust and corrosion

🔸 Easy to clean, perfectly suitable for food processing environments

🔸 Practical design supports continuous operation and high production capacity

📐 Technical Specifications:

Item Details

✅ Machine Number 007

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 4.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 230 cm

✅ Width 80 cm

✅ Height 170 cm

🔍 Features of the Vibrating Potato Sorter:

✔️ Precise vibrating motion for accurate sorting and feeding

✔️ Prevents potato clumping and sticking before cutting

✔️ Four stages separate and evenly distribute the potatoes

✔️ Maintains a stable and balanced production flow

✔️ Safe industrial design, easy to maintain and clean

✔️ Reduces malfunctions caused by excessive or irregular feeding

🎯 Who is this machine for?

If you are looking for smoother and more efficient performance in the initial processing stages, the vibrating sorter is the ideal machine to ensure precise and consistent feeding…

It helps you achieve stable production, reduce waste, and improve the quality of the final product.

Start your production line with a smart sorter…

🔧 Because a balanced production line makes a big difference in the final result.

Slicer server

Precise feeding prevents clogs and ensures efficient, continuous production

📦 A key component of the production line

The potato feeder is a vital component in the potato processing line. It is responsible for feeding the slicer machine with potatoes in a consistent and precise manner, maintaining smooth operation and preventing any downtime caused by irregular or uneven feeding.

This component regulates and feeds the potatoes into the slicer machine smoothly and safely, resulting in a more stable and efficient production line performance.

⚙️ How it works:

1️⃣ Consistent, reliable feeding

The feeder delivers measured quantities of potatoes to the slicer machine, preventing overloading or clogging.

2️⃣ Precise mechanical movement

It utilizes a well-designed mechanical system to distribute the potatoes evenly, avoiding damage to the blades or any production line stoppages.

3️⃣ Seamless integration with other machines

The feeder is designed to work seamlessly with the slicer machine, serving as the perfect link that ensures continuous and uninterrupted production.

🛡️ High-Quality Industrial Design:

🔸 Precision-engineered and manufactured in Turkey

🔸 Made entirely of food-grade 304 stainless steel – rust and corrosion resistant

🔸 Hygienic and easy-to-clean design – ideal for food processing environments

🔸 Suitable for continuous operation in high-capacity production lines

📐 Technical Specifications:

Item Details

✅ Machine Number 008

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Rating 1.5 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 150 cm

✅ Width 50 cm

✅ Height 170 cm

🔍 Features of the Slicer Feeder:

✔️ Precise and consistent feeding maintains slicer efficiency

✔️ Prevents jamming and uneven feeding that can cause malfunctions

✔️ Robust industrial design for continuous operation

✔️ Easy to maintain and clean, meeting food safety standards

✔️ Contributes to consistent production line performance from start to finish

✔️ Reduces the risk of slicer damage due to excessive pressure or uneven distribution

🎯 Who is this machine for?

If you operate a potato processing line and want to avoid unexpected downtime and improve slicer efficiency, this slicer feeder is the perfect solution.

🔧 Ensure a precise start to your production line for a professional final result.

✴️ Because consistent feeding makes the difference between intermittent production and continuous, reliable, high-quality output.

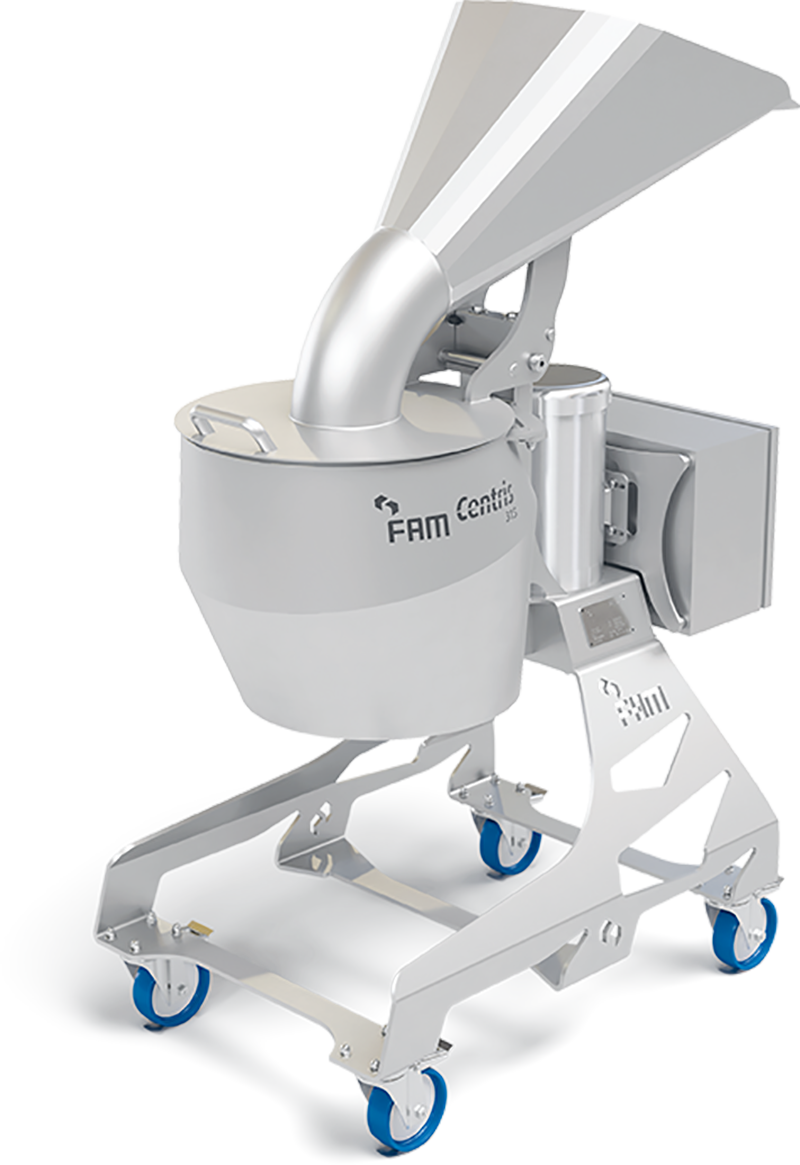

FAM POTATO CUTTING MACHINE

High precision potato slicing with superior European quality. The Belgian potato slicer from FAM guarantees perfect slicing of potatoes without damaging the surface, reducing waste and increasing production efficiency. It produces smooth, uniform slices, both straight and wavy, at high speed, making it the ideal choice for industrial potato processing lines. Its smart design ensures easy operation and cleaning, saving time and money.

⚙️ Advanced Operating Mechanism:

1️⃣ Precise and High-Quality Slicing

✔️ Professional slicing without damaging the potato surface, preserving quality.

✔️ Produces smooth, uniform straight and wavy slices.

✔️ Fast and efficient slicing, reducing waste and increasing productivity.

2️⃣ Easy Operation and Cleaning

✔️ Ergonomic design for easy operation with minimal effort.

✔️ Sliced potatoes are easy to wash, ensuring a clean final product.

✔️ Easy disassembly and assembly, saving time during maintenance and cleaning.

3️⃣ High Performance with Adjustable Thickness

✔️ Adjustable slice thickness for optimal results.

✔️ 1500 blades of each type included with the machine to ensure continuous operation at peak efficiency.

✔️ A powerful motor guarantees high slicing speed and consistent performance.

4️⃣ Durable and Rust-Resistant Construction

✔️ Made entirely of food-grade 304 stainless steel for hygiene and durability.

✔️ High corrosion resistance ensures a long lifespan for the machine. 📏 Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel for hygiene and durability.

✅ Dimensions:

✔️ Length: 120 cm

✔️ Width: 100 cm

✔️ Height: 150 cm

✅ Power: 1.5 kW – 380/220 V – 50 Hz

✅ Machine Number: 009

✅ Model: THV-2024PV-B

✅ Country of Origin: Europe – Made in Belgium by FAM

💡 Why choose the FAM Potato Slicer – THV-2024PV-B?

✔️ Professional slicing without damaging the potato surface, preserving its quality.

✔️ Ability to produce straight-cut and zigzag slices quickly and efficiently.

✔️ Advanced European design by FAM, ensuring the highest quality standards.

✔️ Adjustable slice thickness for desired results.

✔️ Made of food-grade 304 stainless steel for hygiene and easy maintenance.

✔️ Saves time and money thanks to its ease of operation, cleaning, and maintenance.

🔹 The ideal solution for slicing potatoes with the highest quality and efficiency!

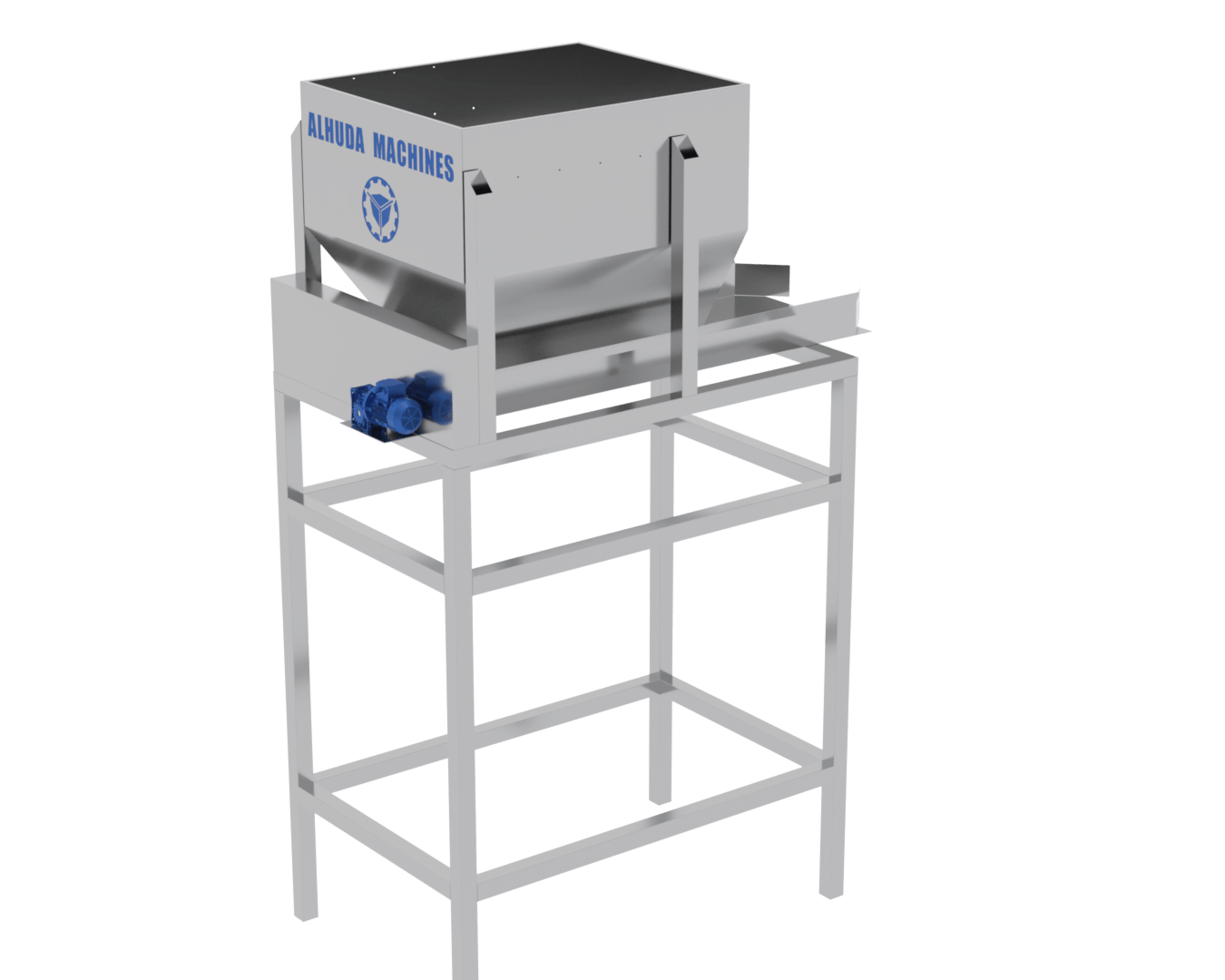

Potato starch extraction and potato chip processing machine

Advanced potato slice processing with a dual water and air system for superior frying quality

🧼 The essential pre-frying stage

This machine is a crucial step in the potato processing line. It precisely removes excess starch and sugars from the potato slices, improving texture, extending shelf life, and enhancing frying quality.

It utilizes an innovative water and air system, employing high-pressure water and compressed air in a "whirlpool" effect, to ensure continuous agitation and effective washing of the slices within a closed cylindrical tank.

⚙️ Smart operating mechanism:

1️⃣ Whirlpool principle (water + air)

High-pressure water and air are pumped to gently agitate the potato slices within the cylindrical tank, effectively removing trapped sugars and starch.

2️⃣ Rotating cylindrical tank

This maintains continuous movement and flow of the potatoes throughout the processing time. The dwell time in the tank can be adjusted according to the potato type and slice size.

3️⃣ Final high-pressure rinse

As the slices exit the machine, they pass under high-pressure water sprays, removing any remaining starch from the surface, ensuring a clean product ready for frying.

4️⃣ Variable speed conveyor belt

The conveyor belt is equipped with a variable speed motor controlled by an inverter, allowing precise adjustment of the processing time.

5️⃣ Dual High-Pressure Pumps

🔹 Air pump for optimal jacuzzi effect

🔹 Water pump for washing nozzles, with adjustable pressure and direction

6️⃣ Safe Lifting Mechanism for the Mobile Tank

The upper part of the machine is raised and lowered using four hydraulic cylinders operating on an oil pressure system, ensuring complete safety during operation or maintenance.

🛡️ High-Quality Construction and Reliability:

🔸 Professionally manufactured in Turkey

🔸 Made entirely of food-grade 304 stainless steel – rust and corrosion resistant

🔸 Designed to meet hygiene and safety standards in the food industry

🔸 Suitable for continuous operation in large production lines

📐 Technical Specifications:

Item Details

✅ Machine Number 010

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 5.25 kW

✅ Voltage 380/220VAC – 50Hz

✅ Length 600 cm

✅ Width 140 cm

✅ Height 200 cm

🔍 Features of the Starch Removal Machine:

✔️ Effective removal of starch and sugars for improved frying quality

✔️ Water and air jacuzzi system for thorough cleaning of the slices

✔️ Adjustable processing time depending on the type of potato

✔️ High-pressure water nozzles with adjustable angle and pressure

✔️ Hydraulic system for safe lifting of the mobile part

✔️ Ideal for production lines requiring consistent and fast performance

✔️ Industrial design, easy to clean and maintain

🎯 Who is this machine for? If your goal is to improve the quality of your final product and ensure consistently crispy and uniform French fries, this starch removal machine is an essential and indispensable part of your production line.

🔧 Because smart preparation of potato slices… starts here

🌊 The quality of frying begins with the quality of water treatment

VIBRATOR FOR DRYING WATER AND SEPARATING THE SLICES

Instant drying after boiling to ensure perfect separation of potato chips

🧊 A crucial step before frying

The vibrating dewatering machine is a key component of the potato chip production line. It efficiently and gently removes excess water after the boiling process, preventing the chips from sticking together and maintaining their quality as they move to the next stages.

Thanks to its high-frequency vibration, this machine provides an effective way to dry the chips without damaging their delicate structure.

⚙️ Smart operating mechanism:

1️⃣ High-frequency vibration

Excess water is removed through precise, controlled vibration, ensuring that the potato slices are evenly distributed and quickly lose surface moisture without breaking.

2️⃣ Uniform transfer to the next stage

The machine regulates the movement of the chips and transfers them directly to the next stage of the production line, maintaining a smooth and uninterrupted workflow.

3️⃣ Bottom tray for water collection

A collection tray at the bottom of the machine gathers the water from the dewatering process, keeping the production area clean and facilitating easy drainage. 🛡️ High-quality construction, ideal for delicate products:

🔸 Precision-engineered and reliable Turkish manufacturing

🔸 Made of food-grade 304 stainless steel – rust-resistant and easy to clean

🔸 Suitable for handling fragile products like potato chips, without damage or breakage

🔸 Operates efficiently in high-capacity production lines

📐 Technical Specifications:

Item Details

✅ Machine Number 011

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 170 cm

✅ Width 100 cm

✅ Height 160 cm

🔍 Features of the Vibrating Dehydrator:

✔️ Fast and efficient drying of potato chips after cooking

✔️ Prevents sticking and preserves the delicate structure of the chips

✔️ High-frequency vibration without causing damage or cracking

✔️ Clean and durable industrial design

✔️ Bottom tray for collecting excess water

✔️ Ready for continuous operation in high-performance production lines

🎯 Who is this machine for?

If you are looking for a smart and efficient solution to reduce moisture content in potato chips before frying or freezing, the vibrating dehydrator is the ideal choice to maintain:

✅ Chip quality

✅ Smooth production flow

✅ Reduced downtime and malfunctions

🔧 Excess moisture means loss… Proper drying means a perfect product.

Hot air drying tunnel

🔥Professional heat drying for improved frying quality and guaranteed crispiness

🌬️Effective drying before frying

The hot air potato dryer is an essential step in the processing of potato slices after boiling. It removes moisture from the potato slices by exposing them to controlled streams of hot air, ensuring:

✅ Reduced water content in the slices

✅ Perfect crispiness after frying

✅ Protection of the oil from contamination or degradation

✅ Prevention of clumping or sticking of the slices

⚙️Smart operating mechanism:

1️⃣ Conveyor belt with integrated heating system

The potato slices are transported on a special conveyor belt, exposed to direct streams of hot air, which contributes to thorough and precise drying.

2️⃣ Electric heaters + 6 fans

An internal heating system utilizes powerful electric heaters, with six fans that distribute the hot air evenly within a closed circuit, ensuring consistent temperature and faster drying.

3️⃣ Air pressure for enhanced efficiency

The heating process is further enhanced by directed air pressure, which boosts the drying speed and efficiency without affecting the shape or texture of the slices.

4️⃣ Closed thermal circuit

A smart design that minimizes heat loss and energy consumption, maintaining a stable thermal environment inside the machine for optimal performance.

🛡️ High-Quality Industrial Equipment:

🔸 Precision-engineered in Turkey to European standards

🔸 Made of food-grade 304 stainless steel – rust-resistant and easy to clean

🔸 Suitable for high-capacity food production environments

🔸 Supports continuous operation without performance decline

📐 Technical Specifications:

Item Details

✅ Machine Number 012

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 9.75 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 160 cm

🔍 Features of the Hot Air Dryer:

✔️ Efficient internal and external drying of potato slices

✔️ Prevents sticking and clumping of the slices

✔️ Facilitates the frying process and keeps the oil clean

✔️ Fast and evenly distributed heating system

✔️ Closed-loop system to minimize heat loss and improve efficiency

✔️ Durable, hygienic, and easy-to-maintain industrial design

🎯 Who is this machine for?

If you aim to enhance the quality of your fried potatoes in terms of crispiness, color, and cleanliness, then a hot air dryer is an essential and indispensable piece of equipment for your production line.

🔧 The less moisture, the crispier and better-tasting the potatoes will be.

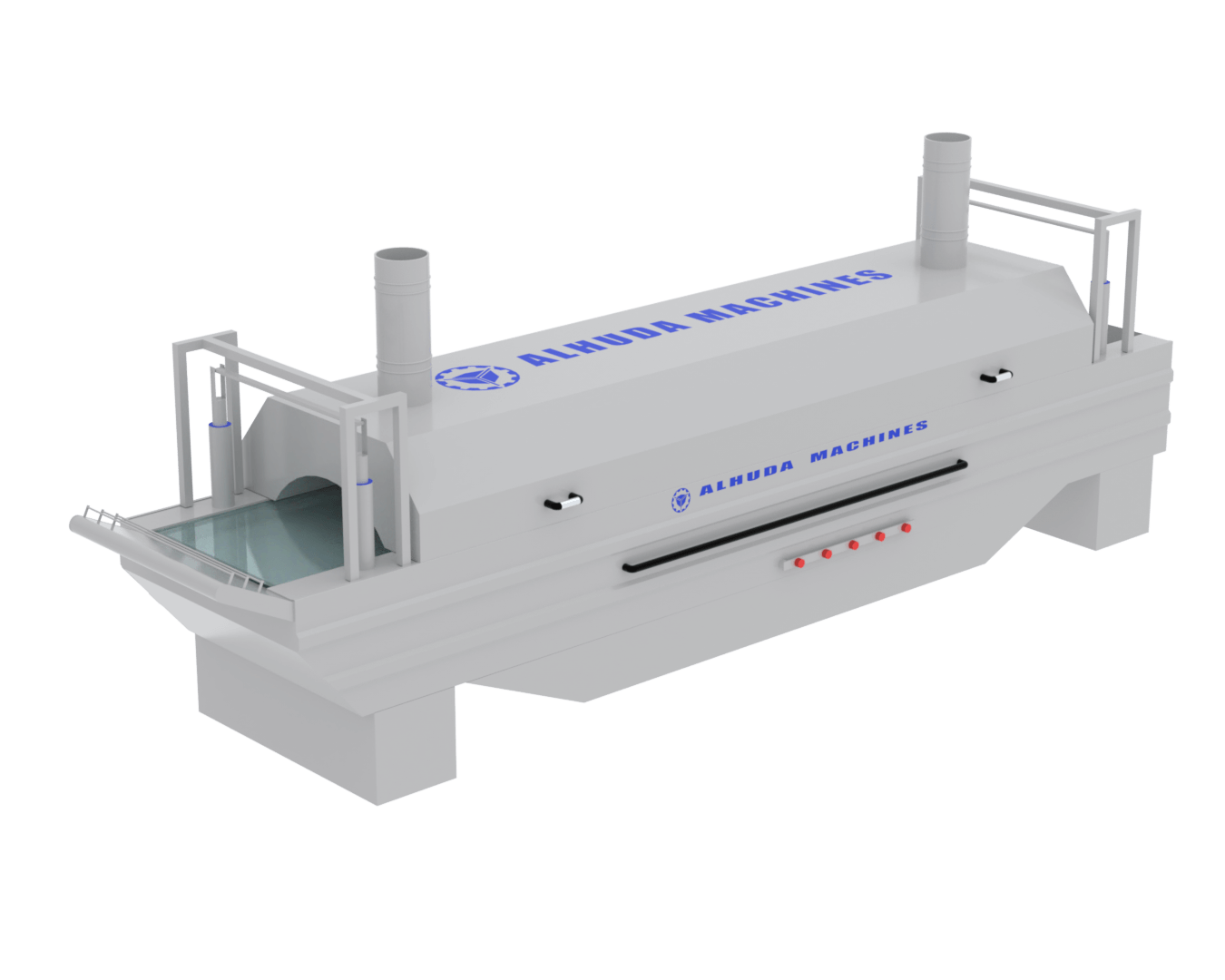

Continuous fryer

Professional frying at precise temperatures and with high-quality oil for the best crispy potato results

🔥 The heart of the production line – Smart frying

The industrial fryer is a key component for quality in potato production.

It uses an indirect heating system with an external heat exchanger (boiler), which maintains stable oil temperature and prevents oil degradation.

Thanks to continuous agitation and advanced temperature control, this machine ensures even and thorough frying of every potato slice, resulting in a golden, crispy product, free from blemishes or burning.

⚙️ Smart operating mechanism:

1️⃣ Indirect heating via an external boiler

An external heat exchanger is used to heat the oil, preventing it from burning and preserving its flavor and quality for longer.

2️⃣ Continuous agitation inside the fryer

The potato slices move automatically in a controlled, circular motion inside the oil bath, ensuring complete immersion and continuous stirring.

3️⃣ Conveyor belt with inverter control

The speed of the conveyor belt, which transports the potatoes, is controlled by an inverter-driven motor, allowing adjustment of the frying time according to the desired product type.

4️⃣ Precise PID temperature control

A smart PID control system maintains the oil temperature with high precision, minimizing quality variations between batches.

5️⃣ Advanced safety system for emergencies

In case of power failure or malfunction, the potatoes can be automatically lifted out of the oil by a built-in hydraulic system, preventing burning or damage. 🛡️ Hygiene, safety, and sustainability:

🔄 Three-stage oil filtration system

Continuously filters the oil during frying to maintain oil purity and flavor quality.

Equipped with a high-capacity pump (100,000 liters/hour).

🧯 Complete thermal insulation

The fryer is fully insulated with 12 cm of insulating material on all sides, protecting against heat and ensuring the safety of operators.

🧼 Easy maintenance and cleaning

Features convenient access panels for cleaning and maintenance, as well as drain ports for used oil. 🛢️ Oil and Filtration Systems:

🛢️ Double-jacketed tanks with heaters

✅ 2 clean oil tanks – each with a capacity of 800 liters

✅ Oil recovery tank – capacity: 800 liters

✅ All tanks are equipped with heaters to maintain oil temperature

💨 Dual steam vents

For oil vapor discharge and pressure regulation inside the fryer

📐 Technical Specifications:

Item Details

✅ Machine Number 013

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 20.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 800 cm

✅ Width 150 cm

✅ Height 200 cm

🔍 Features of the Industrial French Fryer:

✔️ Indirect oil heating for superior product quality

✔️ Continuous agitation for even heat distribution

✔️ Automatic safety system in case of power outage

✔️ PID temperature control for precise temperature management

✔️ Three-stage continuous oil filtration

✔️ Professional thermal insulation and high operational safety

✔️ Large, separate oil tanks with internal heaters

✔️ Practical design and easy maintenance

🎯 Who is this machine for?

If your goal is to produce high-quality French fries with consistent color and crispness, that stay fresh longer without oil degradation, then this fryer is the heart of your production line.

🔧 Because frying perfection… equals market success.

OIL DRYING VIBRATOR

Precise removal of excess oil after frying… for lighter, tastier, and crunchier potato chips

💧 An essential step after frying

This machine removes excess oil from fried potato chips using a high-frequency vibration system, which contributes to:

✅ Improved quality of the final product

✅ Preventing chips from sticking together

✅ Maintaining the chips' shape without breakage

✅ Reducing the fat content of the product

This step is essential for producing crispy, light potato chips that are more appealing to consumers.

⚙️ Smart operating mechanism:

1️⃣ High-frequency vibration

The fried chips are gently conveyed on a belt using a powerful, controlled vibration to effectively drain the surface oil without damaging the chips.

2️⃣ Four progressive stages for oil filtration

The conveyor belt is designed to operate in four sequential movement stages, which help to remove the oil gradually and evenly, preventing oil buildup or saturation of the chips.

3️⃣ Prevents sticking and breakage

The vibration system prevents the chips from sticking together or piling up, and it reduces mechanical friction that could cause breakage.

🛡️ Industrial Quality and Reliable Performance:

🔸 Professionally manufactured in Turkey

🔸 Made entirely of food-grade 304 stainless steel – rust-resistant and easy to clean

🔸 Specifically designed to handle delicate products like potato chips

🔸 Supports continuous operation in high-performance production lines

📐 Technical Specifications:

Item Details

✅ Machine Number 014

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 4.5 kW

✅ Voltage 380/220VAC – 50Hz

✅ Length 300 cm

✅ Width 100 cm

✅ Height 140 cm

🔍 Features of the Vibrating Oil Removal Machine:

✔️ Effectively removes excess oil after frying

✔️ Prevents chips from sticking together or breaking

✔️ Gentle, four-stage vibration for efficient oil removal

✔️ Reduces fat content in the final product

✔️ Ideal for thin, crispy potato chips

✔️ Hygienic and easy-to-clean industrial design

🎯 Who is this machine for?

If you want to offer a more professional, lighter-tasting product, this oil removal machine is the perfect post-frying solution to ensure:

✅ Healthier potato chips

✅ Balanced crispiness

✅ Reduced quality loss due to excess oil

🔧 Lighter product = greater customer satisfaction

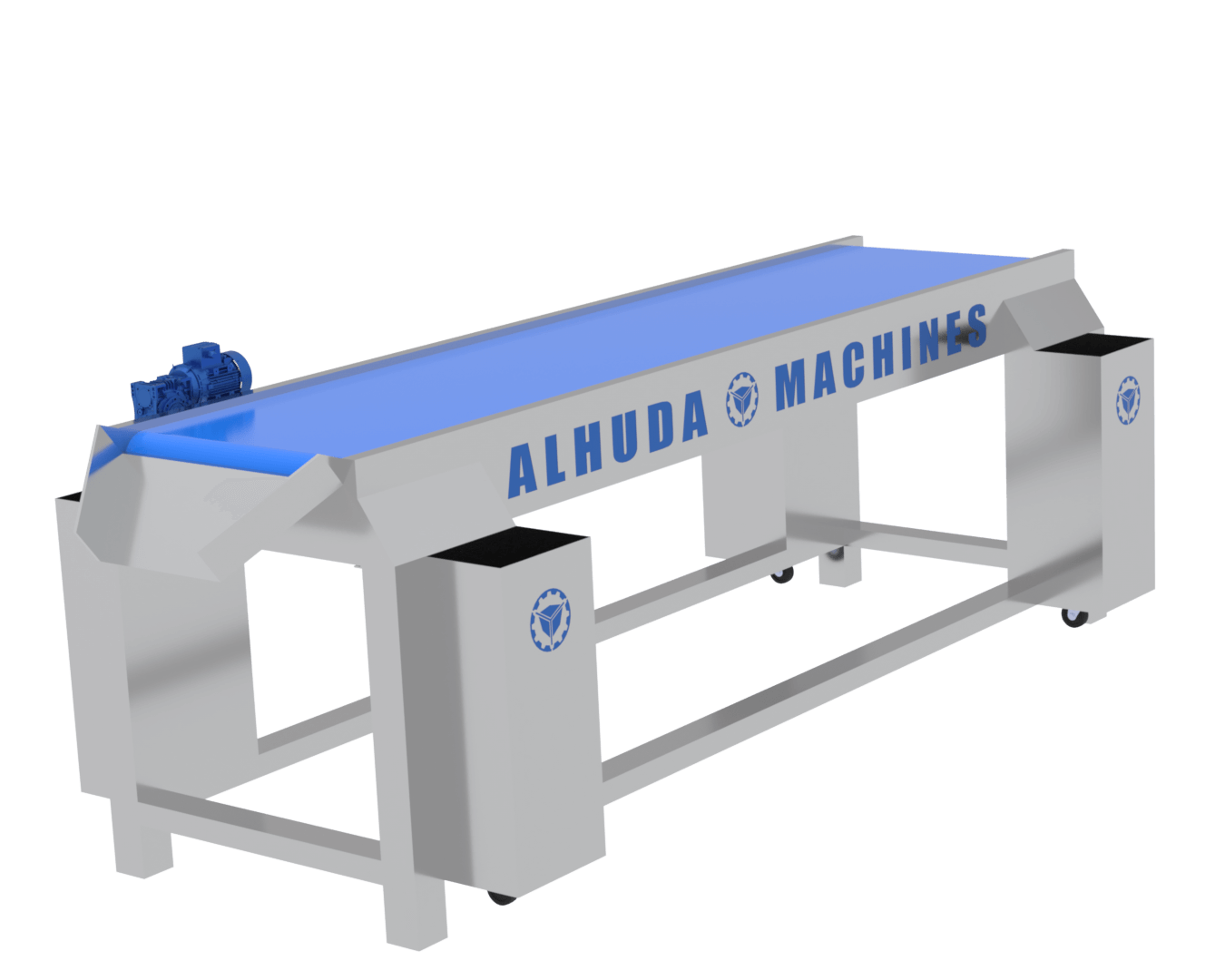

INSPECTION CONVEYOR LINE

👁️🗨️Quality Assurance Inspection Step Before Flavoring and Packaging

🧐 Thorough Inspection Before Packaging

This conveyor belt is used to inspect potato chips after frying and oil removal, and before flavoring and packaging, to ensure:

✅ Removal of damaged or discolored chips (black spots)

✅ Exclusion of non-conforming chips

✅ Maintaining consistent shape and quality of the final product

⚙️ How it works:

1️⃣ Even chip transport

The conveyor belt moves at a consistent speed, allowing human operators or an optional industrial vision system to accurately inspect each chip, either manually or automatically.

2️⃣ Clear and unobstructed inspection area

The conveyor belt is designed with an open surface, making it easy for workers or cameras to see and inspect every chip as it passes along the line.

3️⃣ Ready for integration with flavoring and packaging systems

After inspection, the chips are automatically transferred directly to the flavoring or packaging stage.

🛡️ Professional Manufacturing Quality:

🔸 Precision-engineered in Turkey

🔸 Made of food-grade 304 stainless steel – ideal for food processing environments

🔸 Easy-to-clean surface, safe for food handling

🔸 Designed to streamline the inspection process and minimize waste

📐 Technical Specifications:

Item Details

✅ Machine Number 015

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 1.125 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 400 cm

✅ Width 100 cm

✅ Height 130 cm

🔍 Features of the Visual Inspection Conveyor:

✔️ Enables precise inspection of potato chips before packaging

✔️ Helps to remove damaged or substandard chips

✔️ Ensures consistent product quality

✔️ Practical, open design facilitates easy monitoring and cleaning

✔️ Ideal for the pre-flavoring and packaging stage

🎯 Who is this machine for?

If product quality is your priority, this potato chip inspection conveyor is essential before the flavoring and packaging stage, as it guarantees that only high-quality chips reach the consumer.

🔧 Quality starts with attention to detail.

Flavoring device - spice

🍘 Professional and precise coating for every chip… for a consistent taste and uniform quality

🍥 Balanced flavor on every chip

This machine is a key component in the production line after quality control, as it mixes and evenly distributes the flavor powder onto the potato chips.

This stage ensures:

✅ Uniform coating of all chips

✅ Precise control of the flavor quantity

✅ Improved taste and appearance

⚙️ Smart operating mechanism:

1️⃣ Flavor powder mixing and agitation tank

The tank is equipped with an internal agitator that keeps the flavor powder in a consistent, homogeneous state, preventing clumping or settling.

2️⃣ Horizontal screw feeder

The flavor powder is precisely conveyed from the tank to the spraying unit using a screw feeder designed for dry materials.

3️⃣ Inverter-controlled flow rate

The system is equipped with a motor and an inverter to control the flow rate of the flavor powder to the vibratory feeder, allowing for optimal calibration.

4️⃣ Precise electronic control panel

The system features a dedicated electronic control panel for complete control of the flavor quantity and its even distribution.

🛡️ Food-grade industrial design quality:

🔸 High-quality Turkish manufacturing

🔸 Made entirely of food-grade 304 stainless steel – rust-resistant and easy to clean

🔸 Engineered design for continuous and precise operation

🔸 Ideal for dry powders, such as all types of chip seasonings

📐 Technical Specifications:

Item Details

✅ Machine Number 016

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 2.25 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 140 cm

✅ Width 80 cm

✅ Height 160 cm

🔍 Features of the Flavoring Mixer and Dispenser:

✔️ Continuous and uniform mixing of flavoring powder

✔️ Precise control of the dispensing amount thanks to the inverter

✔️ Spiral design for consistent, clumping-free feeding

✔️ Intelligent electronic control panel for calibration and adjustment

✔️ Hygienic design made of food-grade stainless steel

✔️ Ensures consistent flavor for every chip

🎯 Who is this machine for?

If your goal is to offer a perfectly balanced flavor and taste in your potato chips, this machine guarantees that every chip is coated with the ideal amount of flavoring powder, without any over- or under-seasoning.

🔧 Balanced flavor… the secret to product differentiation and brand loyalty.

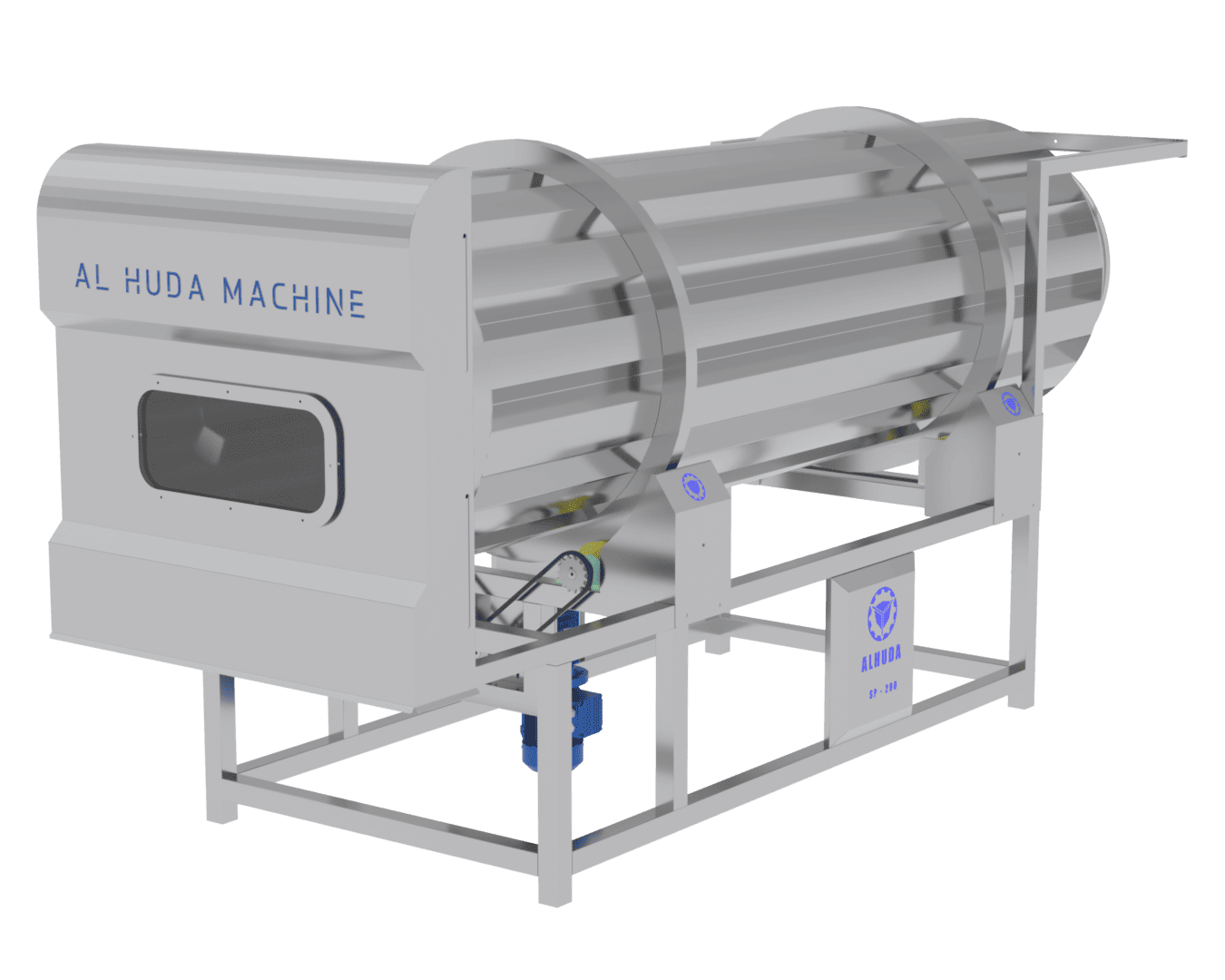

Flavor coating cylinder

Precise flavor distribution... Perfect coating for every chip

🌶️ Uniform rotation and seasoning

The seasoning machine is the final stage in the chip production line, where the potato chips are coated with the final flavor using a precisely calibrated rotating drum system.

The machine relies on slow, consistent rotation of the chips while a fine mist of flavor is applied, resulting in a perfectly seasoned product without clumping or uneven distribution.

⚙️ Smart operating mechanism:

1️⃣ 304 Stainless Steel Rotating Drum

Specially designed to gently rotate the chips during the seasoning process, preventing breakage and excessive friction.

2️⃣ Advanced American Flavor Sprayer

Equipped with a precise, adjustable sprayer that distributes the flavor powder or liquid evenly while the chips rotate inside the machine.

3️⃣ Electronic Speed Control (Inverter)

Easily adjust the rotation speed according to the product type using an inverter-controlled motor, allowing precise control of the seasoning time.

4️⃣ Anti-Clumping Mechanism

The internal baffles are designed to prevent flavor buildup or clumping inside the drum, ensuring precise flavor distribution.

5️⃣ Waste and Residue Removal System

The machine includes a mechanism to remove crumbs, broken chips, and unwanted small pieces, improving the overall product quality.

6️⃣ Chrome Cover and Wheels for Mobility and Cleaning

Features an elegant chrome cover at the product exit and bottom wheels for easy movement within the plant and quick cleaning.

🛡️ Food-grade industrial design quality:

🔸 Manufactured in Turkey to European standards

🔸 Made entirely of food-grade 304 stainless steel – rust-resistant and safe for food

🔸 Easy to disassemble, maintain, and clean

🔸 Designed for continuous operation in professional production lines

📐 Technical Specifications:

Item Details

✅ Machine Number 017

✅ Model THV-2024PV-B

✅ Country of Origin Turkey 🇹🇷

✅ Material Food-grade 304 stainless steel

✅ Power Consumption 3.75 kW

✅ Voltage 380/220 VAC – 50 Hz

✅ Length 300 cm

✅ Width 120 cm

✅ Height 150 cm

🔍 Features of the Drum Seasoning Machine:

✔️ Precise and even flavor distribution on all chips

✔️ High-quality, adjustable American-made flavor sprayer

✔️ Prevents clumping or uneven distribution

✔️ Full control over drum rotation speed and processing time

✔️ Automatic removal of impurities and broken pieces before packaging

✔️ Mobile design for easy cleaning and operation

🎯 Who is this machine for?

If you strive for a final product that satisfies consumer taste with a professional touch in flavor and consistency, this seasoning machine is the key to delivering superior quality.

🔧 The final flavor... is the customer's first impression.

Electrical parts and control panels

Circuit breakers: Schneider brand

Contactors: Schneider brand

Control panel: Delta

Inverters: Delta

Motors: GAMAK

Gearboxes: YILMAZ

Or as per customer request

Basic information

🥔💼 Natural Potato Chips Production Project – From Al Huda Company We present to you today one of the most successful and profitable industrial projects, widely available in various countries and cities. This project is considered a promising venture in the food industry:

🏭 Natural Potato Chips Factory The high and continuous demand for potato chips (natural chips) makes this project a golden opportunity for any investor looking for a guaranteed and successful production business. Potato chips are consumed daily by all age groups and are easily distributed in cities, neighborhoods, and even villages, facilitating sales even in the presence of large competitors.

✅ Why the Natural Chips Project? A product in high demand daily and frequently. Not dependent on a specific season or target audience. Easily scalable geographically. Easy marketing in stores, grocery shops, and supermarkets. Good profit margins and stable operating costs.

🏗️ Natural Potato Chips Production Line – Manufactured by Al Huda Company

🌟 High Quality and European Technology At Al Huda International, we are proud to offer a natural potato chips production line manufactured in Turkey, using advanced German technology, and with over 20 years of experience in this field.

💡 The line operates fully automatically, achieving high-quality production with minimal human intervention, while maintaining the crisp texture and natural flavor of the potato.

⚙️ Main Line Specifications:

🔸 Production Capacity: Starting from 500 kg/hour up to 2 tons/hour (upon request).

🔸 Number of Shapes: More than 3 different shapes, depending on the mold used.

🔸 Approximate Line Length: 70 meters.

🔸 Required Width: Approximately 4 meters. 🔸 Required installation area: approximately 500 square meters.

🔌 Power consumption: approximately 130 kW.

🔧 All parts are made of high-quality 304 food-grade stainless steel.

🛡️ Unmatched quality and guarantee: At Al Huda, we are fully committed to the quality of our production line. We conduct all tests and trials at our factory in Gaziantep, Turkey. We take full responsibility for any defects in specifications or performance.

🔄 If the production line does not meet your requirements, you are entitled to a full refund with no questions asked.

🏆 Why choose Al Huda?

✅ Made in Turkey with German technology.

✅ Over 20 years of experience in manufacturing chip production lines.

✅ Our products are certified with international quality standards.

✅ Continuous after-sales service and technical support.

✅ Production line testing at our factory before shipment.

✅ Possibility of customization according to customer requirements.

📩 For inquiries and to receive a detailed catalog, photos, and videos, please contact us:

💬 Our technical and administrative team is ready to answer all your questions and provide you with complete and detailed information.

🔚 Al Huda – your ideal choice and partner for success, ensuring a successful and reliable business venture.