Corn flakes production line, production capacity 200 kg

🌽🥣 Corn Flakes Production Line

🔹 Overview: A corn flakes production line is a fully integrated industrial system used to manufacture breakfast cereal (corn flakes) from corn and rice. This automated system processes the raw materials from mixing to final packaging. This type of production line is used in food processing plants to produce healthy, crispy, and light breakfast products.

✅ Features: Uses corn or rice as the primary raw material.

Fully automated design. High-quality and consistent production.

Flexibility to change flavors and shapes. Energy-efficient operation.

Easy operation and cleaning.

The line consists of the following parts

1. Corn and rice mixer

2. Screw conveyor

3. Extruder

4. Product conveyor belt

5. Hot air oven

6. Coating drum

7. Flavor and coating solution tanks

8. Coating pump

9. Drying oven

10. Vibrating screen

11. Cooling conveyor belt

12. Conveyor belt for feeding the packaging machines

13. Packaging and sealing machines

Corn and rice mixer

Precise mixing of raw materials – the perfect start for high-quality corn flake production! The corn and rice mixer is a crucial step in corn flake production lines. It mixes corn or rice with additives such as oil and water, adjusting the moisture content and ensuring a homogeneous mixture before heat treatment.

➤ Detailed Functionality:

1. ✅ Mixing Raw Materials: The mixer combines corn or rice with liquids and additives, such as oil and water, to achieve a homogeneous mixture in terms of texture and moisture content.

2. ✅ Adjustable Discharge Opening: Equipped with a precise discharge opening that allows for complete control of the material flow to the next processing stage.

3. ✅ Water Tank with Level Indicator: Features a built-in water tank for precise moisture control, with a visual indicator to measure the liquid level.

4. ✅ Safety Guard: A protective metal mesh prevents the operator's hand from entering the mixing chamber during operation, ensuring safety.

5. ✅ Inspection and Cleaning Opening: The machine is equipped with a top opening for easy monitoring of the mixing process and for convenient cleaning of the mixing chamber.

6. ✅ Magnet for Removing Impurities: The mixing chamber contains a powerful magnetic strip to capture any metallic impurities present in the corn or rice.

7. ✅ High-Quality Food-Grade Construction: The mixer is made entirely of food-grade stainless steel (304), ensuring hygiene, easy cleaning, and maintenance. ➤ Technical Specifications:

Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 180 cm

Width: 120 cm

Height: 230 cm

Mixer capacity: 400 kg

Machine number: 001

Model: THV-2025 CO-R

Country of origin: Made in Turkey

➤ Features of the Corn and Rice Mixer: Ensures a homogeneous and precise mixing of raw materials; Allows control of moisture levels to suit each product; Features advanced safety mechanisms to protect the operator during operation; Durable and high-quality design suitable for continuous operation in a professional food processing environment.

Spiral conveyor

Safe and precise automatic conveying – the perfect solution for corn flakes production lines! The screw conveyor is an essential component in corn flakes production lines, automatically and continuously feeding the raw materials (corn or rice) to the extruder, while ensuring hygiene and industrial safety standards are met.

➤ Detailed operating mechanism:

1. ✅ 75 kg capacity feed hopper: Equipped with a 75 kg capacity hopper to ensure a continuous flow of raw materials to the screw conveyor.

2. ✅ Automatic feeding to the extruder: The screw conveyor transports the corn or rice to the extruder continuously and evenly, without any manual intervention.

3. ✅ Bottom access port for cleaning: Features a bottom access port for easy cleaning and removal of any remaining material.

4. ✅ Operator safety guard: Equipped with a safety mesh that prevents the operator's hand from entering the rotating part, ensuring safety during operation.

5. ✅ Magnetic impurity removal system: Includes a sophisticated magnetic system to capture and remove any metallic impurities that may be present in the corn or rice.

6. ✅ Food-grade industrial design: Made entirely of food-grade 304 stainless steel to guarantee hygiene, ease of cleaning, and easy maintenance. ➤ Technical Specifications:

Power: 1.25 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 90 cm

Height: 250 cm

Tank Capacity: 75 kg

Machine Number: 002

Model: THV-2025 CO-R

Country of Origin: Made in Turkey

➤ Features of the Screw Conveyor: Provides precise and consistent material flow to the production line; enhances workplace safety thanks to its mechanical protection; helps maintain product quality by removing metal impurities; durable and easy-to-service design; ideal for continuous industrial processes in food processing plants.

Extruder

Perfect corn flake shaping – High-precision industrial performance, 24/7! The extruder is the heart of the corn flake production line, puffing and shaping the flakes to the desired design. Using advanced technologies and intelligent control systems, it ensures consistent quality in every batch.

➤ Detailed Operating Mechanism:

1. ✅ Flake Shaping and Puffing: The extruder transforms the corn or rice mixture into corn flakes through pressure and heat, with the ability to control the flake shape using different molds.

2. ✅ Flexible Production Capacity: It can produce 175 to 200 kg of flakes per hour, depending on the desired flake type and shape.

3. ✅ Advanced Industrial Gearbox: Made from high-quality, corrosion-resistant materials, designed for continuous operation 24/7.

4. ✅ High-Quality Bearing System: Equipped with Swedish and Japanese SKF bearings and rotating components for long-lasting performance.

5. ✅ Robust Heating Screw: Made from metal treated in a modern vacuum furnace for superior corrosion resistance and stable operation.

6. ✅ Precise Material Feeding: Features a main screw for feeding the extruder screw, controlled by an electronic inverter.

7. ✅ Dual Cooling Systems: The extruder has both internal water cooling and external air cooling to regulate the operating temperature.

8. ✅ Electronic Cutting Knife: A variable-speed, electronically controlled knife precisely determines the flake length.

9. ✅ Separate Smart Control Panel: An external, sealed, dust-proof control panel with air filters and ventilation for use in hot environments. 10. ✅ Advanced control systems: Fully automatic operation via 3 inverters, with a display for fault codes and a user-friendly control panel for flexibility.

11. ✅ Startup heating system: Equipped with an electronic heating system and a temperature sensor to ensure quick and reliable startup.

➤ Technical Specifications:

Electrical Power: 39.75 kW – 380/220 VAC – 50 Hz

Length: 180 cm

Width: 120 cm

Height: 240 cm

Production Capacity: 175 to 200 kg/hour

Machine Number: 003

Model: THV-2024 CO-R

Country of Origin: Turkey

➤ Extruder Features: Full electronic control of pellet shape and length; reliable and continuous operation thanks to industrial cooling and lubrication systems; advanced external control panel for safe operation and easy maintenance; high-quality food-grade design, ideal for modern corn flake production lines.

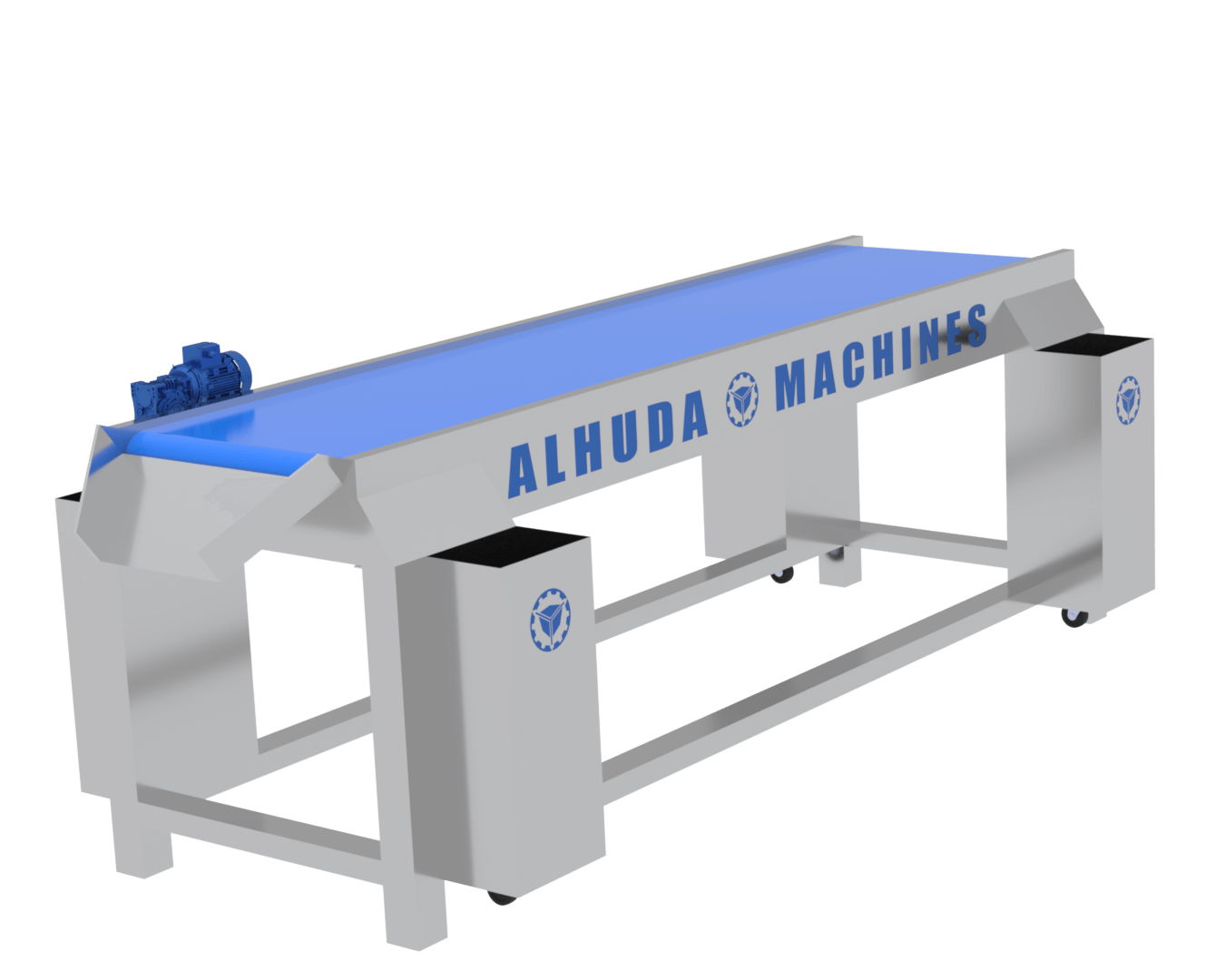

Conveyor belt for the product

Smooth and hygienic material transfer – the perfect solution for moving products from the extruder to the oven! The conveyor belt is a vital component in the corn flakes production line, smoothly transporting the shaped product from the extruder to the oven, while maintaining a clean surface and ensuring easy maintenance and mobility.

➤ Detailed Features:

1. ✅ Wheeled frame: Equipped with robust floor wheels for easy movement and effortless cleaning of the surrounding area.

2. ✅ Durable food-grade belt: The conveyor belt surface is made of PVC or food-grade plastic, ensuring hygienic and safe transport of the corn flakes without contamination or sticking.

3. ✅ Integrated cleaning slots: Features dedicated slots that allow for easy cleaning of both the inside and outside of the belt without disassembly.

4. ✅ Automatic cleaning brushes: Equipped with automatic brushes that continuously clean the belt during operation, ensuring a clean production environment.

5. ✅ High-quality industrial design: Made entirely of food-grade 304 stainless steel for corrosion resistance and easy daily cleaning. ➤ Technical Specifications:

Power: 1.25 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 80 cm

Height: 200 cm

Machine Number: 004

Model: THV-2025 CO-R

Country of Origin: Turkey

➤ Features of the Conveyor Belt: Ensures smooth and safe material transport between production stages; easy to move and clean thanks to its smart design and casters; maintains product hygiene with a continuous cleaning system specifically designed for demanding food processing environments.

Grilling and roasting oven

Balanced roasting and optimal thermal performance – for the best results in corn flakes production! The roasting oven is the essential thermal processing stage in the corn flakes production line. The grains are roasted at high temperatures with precise air distribution, ensuring a crisp texture and perfect flavor. The system utilizes advanced American hot air technology, offering the highest levels of efficiency and operational flexibility.

➤ Detailed Features:

1. ✅ Hot air roasting oven: Equipped with American hot air drying and roasting technology, reaching temperatures up to 300°C.

2. ✅ High production capacity: Produces up to 300 kg per hour, making it ideal for medium to large production lines.

3. ✅ Multiple fuel options: Operates on diesel or natural gas (LPG) for flexible operational choices.

4. ✅ Automatic cleaning system: The internal conveyor belt features a self-cleaning system to maintain cleanliness without production downtime.

5. ✅ Independent control for each layer: Each layer has its own motor and inverter for precise control of belt speed and roasting temperature.

6. ✅ Intelligent temperature control: Two programmable temperature controllers ensure consistent roasting temperature.

7. ✅ Removable heating chambers: Two removable heating chambers for easy maintenance and inspection.

8. ✅ Comprehensive thermal insulation: Encased in 12 cm of fiberglass insulation on all sides for optimal heat retention and energy efficiency.

9. ✅ Optimal air distribution: Top and bottom air distribution system with side recirculation for even roasting.

10. ✅ Dual thermal fans: Equipped with one fan to exhaust hot air and another to draw in and circulate air internally.

11. ✅ Advanced control panel: A separate, removable control panel with a touchscreen, a text-based fault diagnostics system, and full control of the air circulation fans via inverters.

➤ Technical Specifications:

Power: 10.5 kW – 380/220 VAC – 50 Hz

Length: 700 cm

Width: 150 cm

Height: 220 cm

Machine Number: 005

Model: THV-2025 CO-R

Country of Origin: Made in Turkey

➤ Features of the Hot Air Convection Oven: Provides even roasting with efficient heat distribution, allowing for flexible operation using either gas or diesel. Features advanced cleaning, cooling, and air distribution systems. A professional design suitable for continuous operation in food processing plants.

Diameter blending mixer with stirring mechanism

Uniform coating for corn flakes – perfect flavor and attractive shine! The syrup coating mixer is a crucial final stage in the corn flake production line. It coats the flakes with syrup (liquid flavor or sugar solution) to achieve the desired final taste and a shiny, appealing appearance. This is accomplished using precise, fully automated spraying and rotating systems.

➤ Detailed Functionality:

1. ✅ Variable speed conveyor belt: The speed of the conveyor belt is electronically controlled by an inverter to precisely adjust the flow rate of the flakes.

2. ✅ Adjustable, automated rotating arm: Equipped with a movable arm that gently rotates and stirs the flakes inside the mixer, ensuring uniform coating. The speed and rotation can be adjusted according to the product type and desired syrup application.

3. ✅ Automatic syrup/flavor spraying system: Features automatically controlled, programmable spray nozzles that distribute the syrup evenly across the entire surface of the flakes.

4. ✅ Precise electronic syrup/flavor dosing: The syrup is pumped at a precisely controlled, electronically adjustable rate to deliver the exact amount needed.

5. ✅ Consistent rotation mechanism: The flakes rotate slowly and evenly inside the mixer, ensuring complete coating without breakage or clumping.

6. ✅ Easy mobility and cleaning: Equipped with casters for easy movement within the plant, and designed for easy daily cleaning.

7. ✅ High-quality food-grade construction: Made entirely of 304-grade stainless steel for food safety and durability.

➤ Technical Specifications:

Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 280 cm

Width: 120 cm

Height: 170 cm

Machine Number: 006

Model: THV-2024 CO-R

Country of Origin: Turkey

➤ Features of the Coating Mixer: Provides a uniform and optimal coating for corn flakes. Ensures precise control of the spraying and coating speed, depending on the product type. Facilitates cleaning and transportation within the factory. Maintains the quality of the final product, giving it an attractive appearance and excellent taste.

Mixer tank diameter

Precise preparation of syrup and flavoring – a dual heating system for optimal coating results! The syrup mixing tank is a vital component in the process of coating corn flakes with sugar or liquid flavorings. The syrup is precisely mixed, heated, and then automatically pumped to the spraying unit.

➤ Detailed Functionality:

1. ✅ Homogeneous mixing of syrup and flavoring: The tank is specifically designed for mixing the liquid flavorings (syrup) used in corn flake coating, with a capacity of 200 liters per tank.

2. ✅ Double-jacket design for indirect heating: Equipped with a double-walled insulation layer, the water surrounding the tank is heated without direct contact with the flavoring, ensuring the integrity and stability of the ingredients.

3. ✅ Integrated system on a single frame: The two tanks and the pump are mounted on a single, heat-treated steel base, fully clad in stainless steel, ensuring durability and ease of cleaning.

4. ✅ Mobile casters: Equipped with sturdy casters for easy movement within the plant and for periodic cleaning around the unit.

5. ✅ Precise temperature control: Features an external temperature gauge to monitor the water temperature in the heating jacket.

6. ✅ Water level indicator: Includes a visual indicator to show the level of hot water in the jacket, ensuring safe and continuous operation.

7. ✅ Fully food-grade design: Made of food-grade 304 stainless steel, guaranteeing hygiene and ease of maintenance.

➤ Technical Specifications:

Power: 3.75 kW – 380/220 VAC – 50 Hz

Length: 200 cm

Width: 120 cm

Height: 170 cm

Capacity per mixer: 200 liters

Machine number: 007

Model: THV-2025 CO-R

Country of origin: Made in Turkey

➤ Features of the twin-tank mixer: Provides consistent flavor mixing with safe indirect heating. Easy to move and clean thanks to its compact design and casters. Equipped with temperature and level indicators for precise control of water temperature and level. Durable, hygienic design, ideal for corn flake production plants.

Syrup pump

A precise system for pumping syrups and flavors using American technology to reduce waste and increase efficiency! This pump is specifically designed for pumping syrups or liquid flavors in snack, popcorn, and corn flakes production lines, ensuring precise dosing and minimizing material consumption. It operates using advanced technology based on an alternating suction and pumping system, guaranteeing a consistent and uniform distribution of the flavor or syrup on the product.

⚙️ How it works:

1️⃣ Automatic suction and pumping: The syrup or flavor is drawn from the tank via a high-quality food-grade silicone hose, then pumped by a geared motor connected to a solid aluminum pump.

2️⃣ Precise electronic control: The pumping volume is electronically controlled via an inverter, allowing for precise adjustment of the syrup or flavor flow according to the product type and specific requirements.

3️⃣ Easy mobility and cleaning: The pump is mounted on a mobile base made of food-grade stainless steel (304) with casters, facilitating easy movement and daily cleaning.

🧰 Technical Specifications:

✅ Model: THV-2025 CO-R

✅ Part Number: 008

✅ Fluid Type: Syrup – Liquid Flavors

✅ Material:

• Pump: Solid Aluminum

• Base: 304 Stainless Steel

• Hose: Food-grade Silicone

✅ Drive Type: Gear Motor-driven Pump

✅ Control System: Inverter for Electronic Flow Control

✅ Power Supply: 380/220VAC – 50Hz – 1.125 Kw

✅ Dimensions:

• Length: 80 cm

• Width: 60 cm

• Height: 70 cm

🇹🇷 High-quality Turkish Made: The ideal choice for factories seeking to improve distribution efficiency and reduce waste, while ensuring ease of operation and maintenance. A precise system for pumping syrup and flavors using American technology to minimize waste and maximize efficiency! This pump is specifically designed for pumping syrup or liquid flavors in snack, popcorn, and corn flakes production lines, maintaining precise dosing and saving on material consumption. It operates with advanced technology based on an alternating suction and pumping system, ensuring a consistent and uniform distribution of flavor or syrup on the product.

Operating Mechanism: Automatic Suction and Pumping: The syrup or food-grade liquid is drawn from the tank through a high-quality food-grade silicone hose, then pumped by a gear motor connected to a solid aluminum pump. Precise Electronic Control: The pumping volume is electronically controlled by an inverter, allowing precise adjustment of the syrup or flavor flow according to the product type and requirements. Easy mobility and cleaning: The pump is mounted on a mobile base made of food-grade stainless steel (304) with casters, facilitating easy movement and daily cleaning.

Technical Specifications:

Model: THV-2025 CO-R

Part Number: 008

Fluid Type: Concentrates – Liquid Flavors

Materials:

• Pump: Solid aluminum

• Base: Stainless steel 304

• Hose: Food-grade silicone

Drive Type: Gear motor connected to the pump

Control System: Inverter for electronic flow control

Power Supply: 380/220VAC – 50Hz – 1.125 kW

Dimensions:

• Length: 80 cm

• Width: 60 cm

• Height: 70 cm

High-quality, made in Turkey. An ideal choice for manufacturers seeking to improve distribution efficiency, reduce waste, and benefit from ease of operation and maintenance.

Hot air drying oven

Complete roasting for optimal flavor – High-precision and efficient thermal performance! The second oven is used in the final stage of corn flake roasting, employing the same advanced hot air system to ensure the perfect crispness, consistent flavor, and uniform size. It utilizes proven American technology, featuring a smart operating system and fully automated cleaning.

➤ Detailed Operating Mechanism:

1. ✅ Hot air roasting and drying oven: Utilizes an American-designed heat distribution system to raise the roasting temperature to 300°C.

2. ✅ Consistent production capacity: Produces 300 kg per hour, ensuring seamless integration with other production stages.

3. ✅ Flexible fuel options: Operates on diesel or natural gas (LPG), allowing for selection based on availability.

4. ✅ Automatic mesh cleaning system: Equipped with an automatic cleaning mechanism to maintain the cleanliness of the corn flake-carrying mesh.

5. ✅ Independent control for each layer: Each layer has its own motor and electronic inverter for precise control of the rotating mesh speed.

6. ✅ Smart temperature control: Two programmable temperature controllers for automatic adjustment of the roasting temperature as needed.

7. ✅ Removable heating chambers: Two easily removable chambers for quick and safe cleaning and maintenance.

8. ✅ Complete thermal insulation: Insulated with 12 cm of fiberglass on all sides to maintain heat and reduce energy consumption.

9. ✅ Intelligent air distribution system: Hot air is distributed from above and below with side recirculation for even roasting.

10. ✅ Dual fans: One fan for circulating hot air and another for drawing in and circulating ambient air to ensure consistent temperature.

11. ✅ Separate control panel: A detachable, independent control panel with a touchscreen and a fault-reporting system via text messages, and inverter-controlled fans.

➤ Technical Specifications:

Power: 10.5 kW – 380/220 VAC – 50 Hz

Length: 500 cm

Width: 150 cm

Height: 220 cm

Machine Number: 009

Model: THV-2025 CO-R

Country of Origin: Made in Turkey

➤ Features of the second oven: Ensures even, consistent roasting after the product has been coated. Maintains stable temperature thanks to the intelligent distribution system. Easy maintenance and transport thanks to its modular design. Designed to meet the highest food safety and industrial quality standards.

Shaker to separate and prevent cornflakes from sticking

Precise separation and anti-clumping – effective protection for corn flakes before packaging! The vibratory separator is an essential final stage in the corn flakes production line. It uses high-frequency vibration to separate any clumps of flakes, ensuring they flow smoothly and individually to the packaging stage without breakage or accumulation.

➤ How it works in detail:

1. ✅ Separates clumpy flakes: Utilizes powerful, precise vibration to separate flakes that have stuck together after roasting or cooling, preserving their original shape.

2. ✅ Prevents breakage during transport: Protects the flakes from breaking by reducing pressure and minimizing clumping before they enter the packaging process.

3. ✅ Three-stage conveyor belt: Features a three-stage, inclined conveyor belt for gradual and controlled separation, increasing efficiency and preventing buildup.

4. ✅ Hygienic industrial design: Made entirely of food-grade 304 stainless steel for corrosion resistance and easy cleaning.

➤ Technical Specifications:

Power: 4.5 kW – 380/220 VAC – 50 Hz

Length: 300 cm

Width: 100 cm

Height: 140 cm

Machine Number: 010

Model: THV-2025 PV-B

Country of Origin: Made in Turkey

➤ Benefits of the vibratory separator: Separates clumpy flakes without damaging their shape. Prevents product breakage before packaging, improving packaging quality. Enhances material flow and increases production line efficiency. Durable and hygienic design, ideal for continuous operation in food processing environments.

Relax and cool down itinerary

A smart industrial solution for receiving hot granules and gradually cooling them before flavoring or packaging! This industrial conveyor is used to receive the product directly after it exits the shaker, where the granules are still hot and require initial cooling and temperature control before proceeding to subsequent stages such as flavoring or packaging. The system gradually reduces the product temperature, helping to maintain its shape and minimizing the risk of sticking or breakage.

⚙️ Technical Specifications:

🔹 Model: THV-2025 CO-R

🔹 Function: Receiving hot product from the shaker – Initial cooling and temperature control

🔹 Material: High-quality, heat-resistant, food-grade stainless steel frame

🔹 Belt type: Heat-resistant stainless steel mesh belt

🔹 Machine number: 011

📏 Dimensions:

▪️ Length: 4 meters

▪️ Width: 80 cm

▪️ Height: 100 cm

▪️ Design: Open sides for ventilation and faster cooling

🔧 Additional Options:

✔️ Durable industrial wheels for easy movement

✔️ Adjustable height as needed

✔️ Option to add cooling fans (upon request)

✅ Why choose this model? • It ensures product integrity after the shaker and prevents damage to the granules • It is made entirely of food-grade, heat-resistant materials • It guarantees smooth and safe product transfer to subsequent stages • It is customizable to suit the product type and production line

💡 The ideal solution to ensure product quality and shape consistency after the shaker, and achieve seamless processing in 2025! Product cooling conveyor after the shaker: A smart industrial solution for receiving hot granules and gradually cooling them before seasoning or packaging! This industrial conveyor is used to receive the product directly after it exits the shaker, where the granules are still hot and require initial cooling and temperature control before proceeding to subsequent stages such as seasoning or packaging.

The conveyor gradually reduces the product temperature, helping to maintain its shape and minimizing the risk of sticking or breakage. Technical Specifications:

Model: THV-2025 CO-R

Function: Receiving hot product from the shaker – Initial cooling and temperature control Material:

High-quality, heat-resistant, food-grade stainless steel frame Conveyor belt: Heat-resistant stainless steel mesh mat

Machine number: 011

Dimensions:

Length: 4 meters

Width: 80 cm

Height: 100 cm

Design: Open sides for ventilation and faster cooling Additional options: Durable industrial wheels for easy movement Adjustable height to suit your needs Optional cooling fans (available upon request)

Why choose this model? Because it ensures the product's integrity after the shaker and prevents damage to the granules. Because it is made entirely of food-grade, heat-resistant materials. Because it guarantees a smooth and safe transfer of the product to subsequent processing stages. Because it is customizable to suit your product type and production line. The ideal solution to ensure product quality and shape consistency after the shaker, and to achieve seamless processing in 2025!

Packing machine feeder conveyor line

Precise and balanced product transfer to maintain quality. The conveyor belt is a crucial part of the corn flakes production process, ensuring efficient transfer of the product from the final stage to three packaging machines, while maintaining the integrity of the flakes thanks to a precise and fully automated distribution system. Advanced operating mechanism:

1️⃣ Precise electronic control system: The product transfer speed is controlled by an electronic control circuit with advanced sensors, allowing for balanced product feeding according to the capacity of the packaging machines.

✅ Equipped with a hopper and vibrator to ensure a consistent flow of corn flakes without any buildup or jamming.

✅ Fully automatic operation minimizes manual intervention and maximizes production efficiency.

2️⃣ Advanced conveyor belt design: Features a Z-shaped PVC belt for smooth product transfer at the optimal angle, ensuring consistent flow without damaging the flakes.

✅ Made of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Its design minimizes vibrations and shocks, protecting the product from breakage.

3️⃣ Smart sensors for enhanced performance: Equipped with advanced electronic sensors that automatically adjust the product speed and flow, preventing any buildup or congestion on the production line.

✅ Ensures even distribution of the product to the packaging machines for consistent and reliable production.

4️⃣ Durable and easy-to-clean design: Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning, with a robust structure to withstand continuous industrial use.

✅ Equipped with sturdy casters for easy movement and maintenance. Technical Specifications:

✅ Material: Made entirely of food-grade 304 stainless steel for the highest hygiene and quality standards.

✅ Power: 5.25 kW | 380/220 V | 50 Hz

✅ Dimensions:

Length: 14 cm

Width: 90 cm

Height: 380 cm

✅ Machine Number: 012

✅ Model: THV-2025 PV-Z

✅ Country of Origin: Turkey Features of the Conveyor Belt:

✔️ Precise electronic control system with sensors for automatic adjustment of product transport speed.

✔️ Z-shaped PVC belt ensures smooth and consistent product flow without affecting product quality.

✔️ Impact and vibration-resistant design protects products from breakage.

✔️ Hopper and vibrator ensure even product flow and prevent product buildup during transport.

✔️ Made entirely of food-grade 304 stainless steel for rust resistance and easy cleaning.

✔️ Equipped with sturdy casters for easy movement and cleaning, making it ideal for industrial environments.

💡 The perfect solution for efficient product transport and ensuring the highest quality in production!

Continuous system weight packaging machines No.3

Automatic Weighing and Packaging Machine – Continuous Filling System

High performance, 24/7! We present an exceptional packaging machine, designed to the highest international standards to meet the demands of the modern food industry. This machine is the ideal industrial solution for accurately, quickly, and consistently packaging light products such as chips, potato sticks, seeds, nuts, and other dry goods. The machine features a fully servo-driven system, eliminating traditional mechanical components, resulting in significantly reduced downtime and maintenance, increased operational lifespan, and outstanding performance stability. Exceptional features that make this machine the best in its class:

✅ Continuous filling system with a conveyor belt for uninterrupted production.

✅ High output: 90 to 120 packages per minute (depending on weight).

✅ 14 highly sensitive and accurate weighing scales from HIGH DREAM.

✅ DELTA (Taiwan) PLC controller – instant response and precise operation.

✅ 7-inch DELTA touchscreen – complete and easy control of all machine functions.

✅ High-precision OMRON temperature control system – fully adjustable via the touchscreen.

✅ Automatic film feed system with a smart compensating motor and end-of-roll sensor.

✅ Durable food-grade 304 stainless steel frame – easy to clean.

✅ Completely free of mechanical complexities – relying solely on servo and stepper motors, resulting in virtually no maintenance. Why choose this machine?

⭐ Because it's built to last – robust and durable, designed for continuous, 24/7 operation.

⭐ Because it operates smoothly without any interruptions or unexpected breakdowns.

⭐ Because it utilizes advanced servo technology, ensuring the highest accuracy in weighing and filling.

⭐ Because it offers flexibility in adjusting size, weight, bag length, and production sequence.

⭐ Because it is user-friendly – easy to operate with a smart and simple interface. Included components:

🔹 Feed conveyor with hopper and vibrator – for efficient product feeding.

🔹 Conveyor for finished packages.

🔹 Date printer.

🔹 Mounting platform for the weighing scale. Technical specifications:

⚙️ Power: 5.75 kW – 380/220 V – 50 Hz.

📐 Dimensions:

Length: 500 cm

Width: 300 cm

Height: 420 cm

🆔 Model number: 013

Why choose Al Huda? Al Huda is not just a manufacturer; we are a trusted industrial partner that prioritizes quality and precision. With extensive experience in manufacturing packaging and filling lines, we strive to provide machines that combine European technology with high operational efficiency. Al Huda is proud that this specific model, the THV-2024PV-B, has become the preferred choice for food processing plants seeking to improve efficiency and reduce downtime, thanks to its fast, accurate, and reliable performance. Choose Al Huda... because quality starts here. A comprehensive and detailed description of the continuous weighing packaging machine has been written, emphasizing its strength, durability, ease of operation, and Al Huda's expertise. You can now review the text in the sidebar. Would you like me to convert it to a Word document for downloading and printing?

Electrical parts and control panels

Circuit breakers: Schneider brand

Contactors: Schneider brand

Control panel: Delta

Inverters: Delta

Motors: GAMAK

Gearboxes: YILMAZ

Or as per customer request

Basic information

✨ Corn Flakes Production Line – 200 kg/hour Capacity ✨

By Al Huda, a leading manufacturer of food processing equipment

The corn flakes production line is one of Al Huda's latest innovations, combining advanced European technology and modern industrial design to produce a high-quality product that meets international food safety standards.

This fully automated line, from raw material preparation (corn or rice) to final packaging, is the ideal solution for factories looking to produce high-quality, flavorful corn flakes efficiently.

🔹 Key Stages of the Production Process

The line consists of a fully integrated system of machines that work seamlessly together to ensure the production of crisp, high-quality flakes.

1️⃣ Corn/Rice Mixer

🔹 Mixes corn or rice with water, oil, and other ingredients to create a homogeneous mixture, ideal for the extrusion process.

2️⃣ Screw Conveyor

🔹 Automatically transports the mixture to the extruder, maintaining consistent flow and ease of operation.

3️⃣ Extruder

🔹 The heart of the production process, where the flakes are formed under precise pressure and temperature, allowing for control of shape, size, and production capacity up to 200 kg/hour.

4️⃣ Conveyor Belt

🔹 Transports the extruded flakes to the roasting stage without any loss of quality or breakage.

5️⃣ Hot Air Roasting Oven

🔹 The flakes are roasted to achieve the desired golden color and crisp texture, while preserving their nutritional value.

6️⃣ Coating and Flavoring Drum

🔹 To coat the wafers with a layer of sugar, honey, or special flavors, adding a distinctive taste and enhancing the product's appeal.

7️⃣ Flavor and Coating Mixing Tanks

🔹 Prepare pre-mixed flavors and liquids with heating and stirring systems to ensure consistent flavor.

8️⃣ Coating Pump

🔹 Precisely pumps the flavors to the drum, with controlled flow rate.

9️⃣ Drying Oven

🔹 Removes excess moisture to ensure the wafers remain crispy and have a long shelf life.

10️⃣ Vibrating Separator

🔹 Separates any stuck wafers and prevents clumping, resulting in a uniform final product.

11️⃣ Cooling Conveyor

🔹 Gradually cools the wafers before packaging to maintain their texture and prevent moisture absorption.

12️⃣ Conveyor for Packaging Machines

🔹 Regulates the flow of wafers and delivers them to the packaging machines smoothly and consistently.

13️⃣ Packaging and Sealing Machines

🔹 Packs the final product in airtight bags using precise weighing systems, with attractive packaging that preserves freshness.

🔹 Technical Specifications and Features

✔️ Production Capacity: Up to 200 kg/hour.

✔️ Fully Automatic Operation: From raw materials to final packaging.

✔️ 304 Stainless Steel Construction: Ensures hygiene, easy cleaning, and compliance with global food safety standards.

✔️ Advanced Safety Systems: Emergency stop, protection against accidental operation, and safety doors.

✔️ Intelligent Electronic Controls: Digital control panels, temperature sensors, and frequency inverters for speed adjustment.

✔️ High flexibility: Easily adjust the shape, size, and flavor of the cereal flakes.

✔️ Superior product quality: Crispy, light, and well-balanced flavor—perfect for both local and international markets.

🔹 Why choose Al Huda's corn flakes production line?

Over 20 years of experience in the food processing industry.

State-of-the-art European and German technology.

Durable, robust design with a long operational lifespan.

Continuous technical support and after-sales service.

Guaranteed results and internationally competitive quality.

✨ Conclusion

With Al Huda's 200 kg/hour corn flakes production line, you're not just buying a machine; you're investing in a complete production system that delivers:

Quality – Speed – Reliability – High profitability.

Gallery